high speed 0.12-0.3mm G550 material metal corrugated sheet roll forming machine

Key words:

Product category:

Tel/Whatsapp:

high speed 0.12-0.3mm G550 material metal corrugated sheet roll forming machine

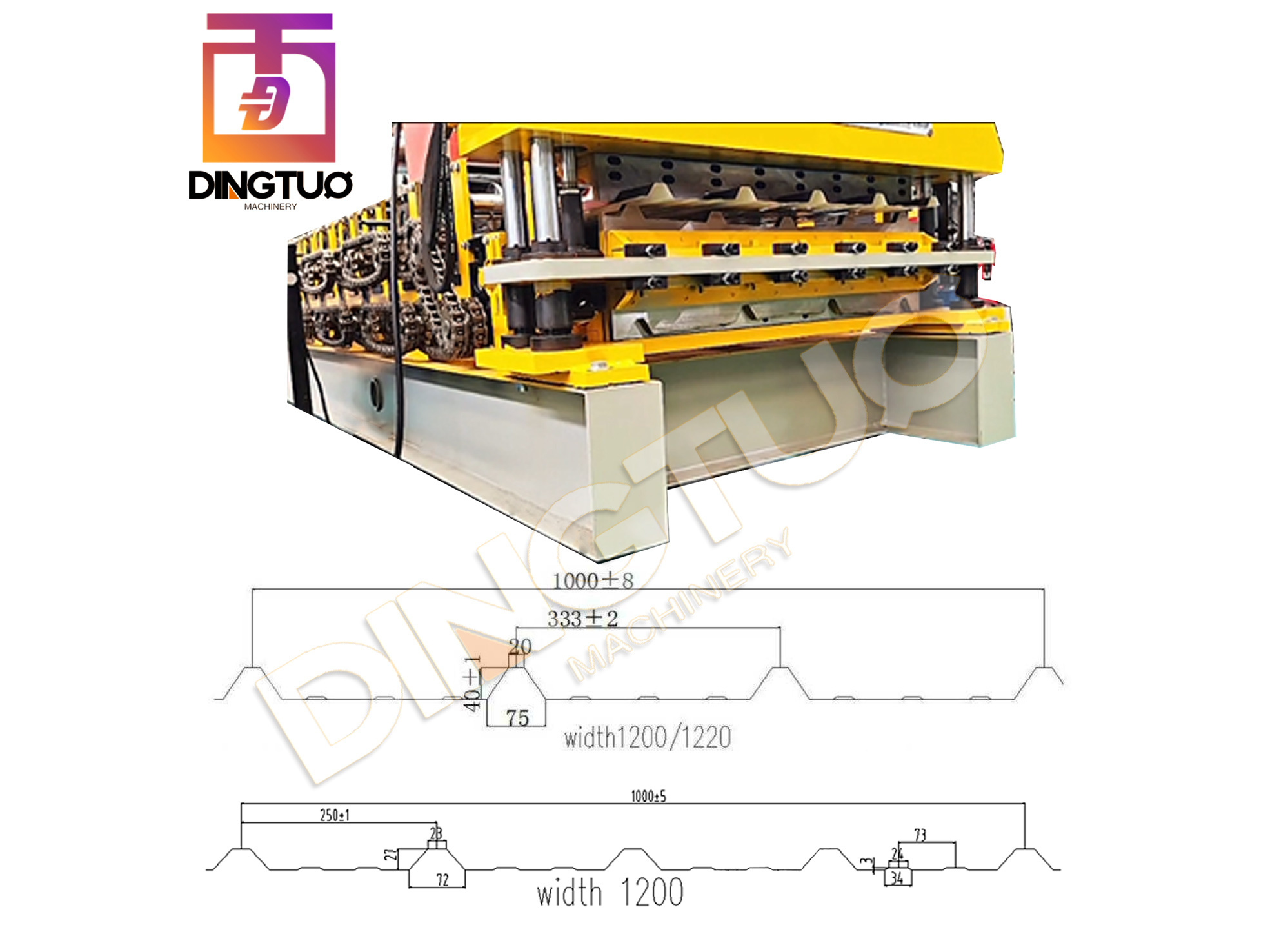

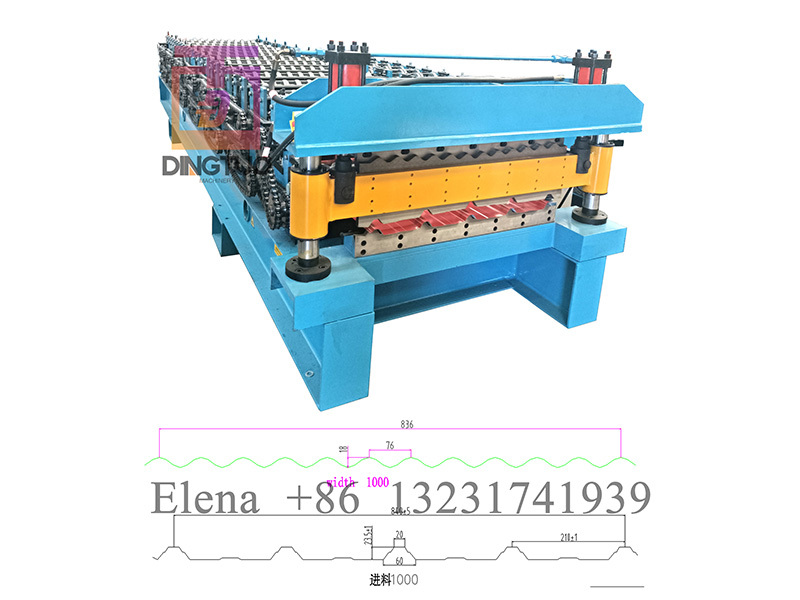

RELATED MACHINES

0.12 MM G550 MATERIAL METAL CORRUGATED ROOFING SHEET ROLL FORMING MACHINE

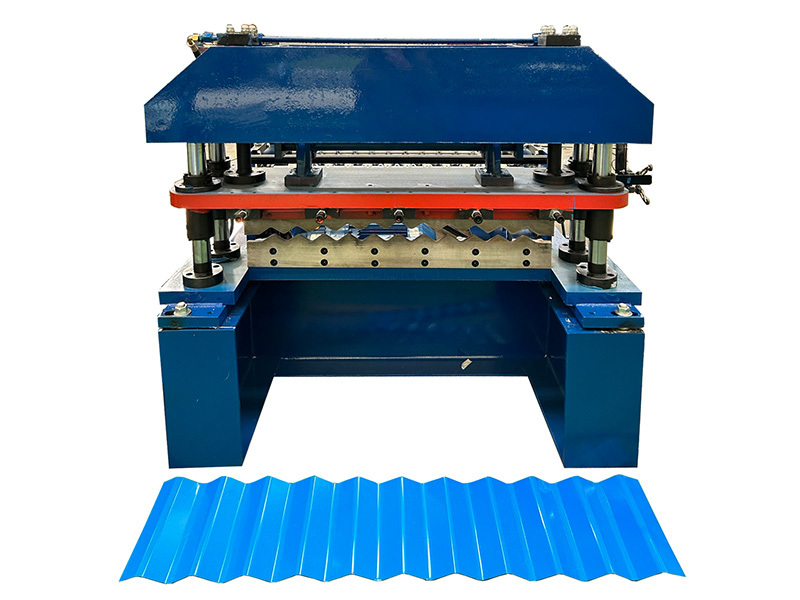

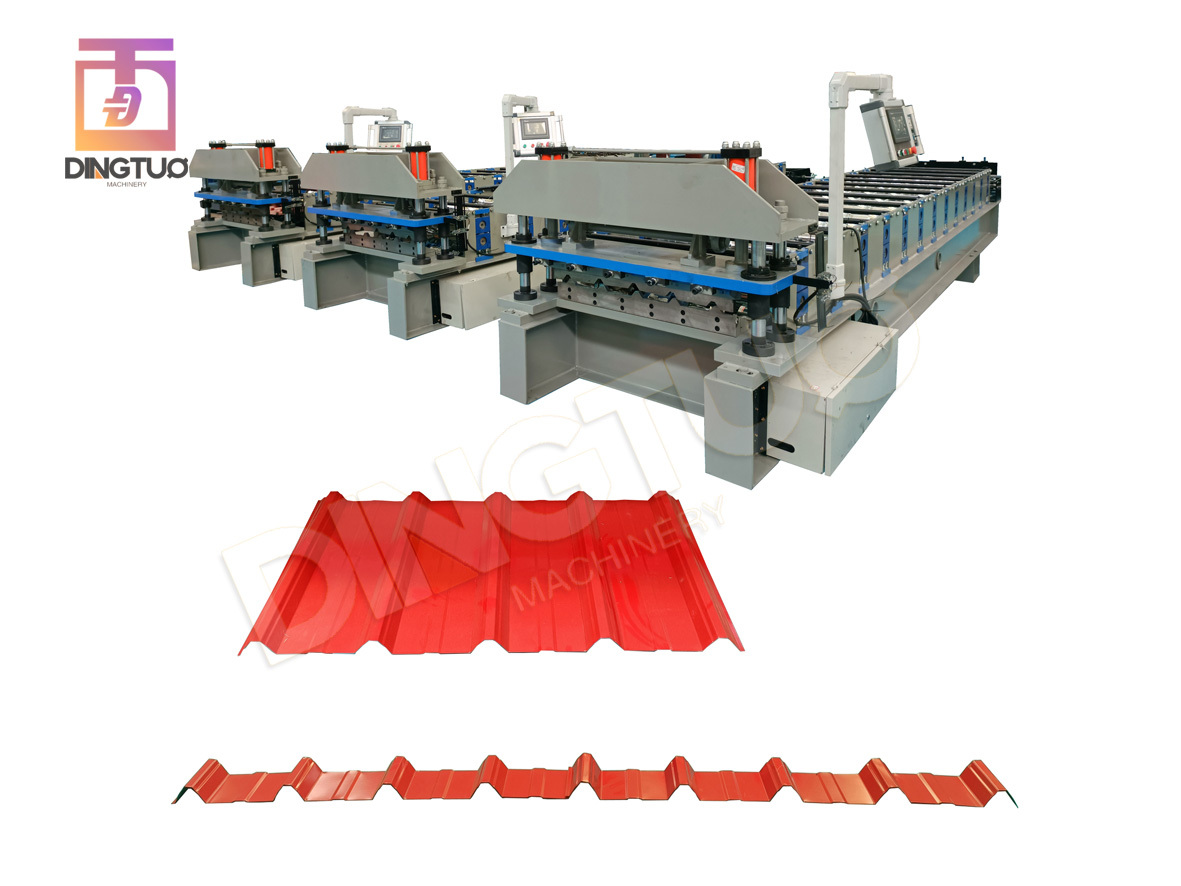

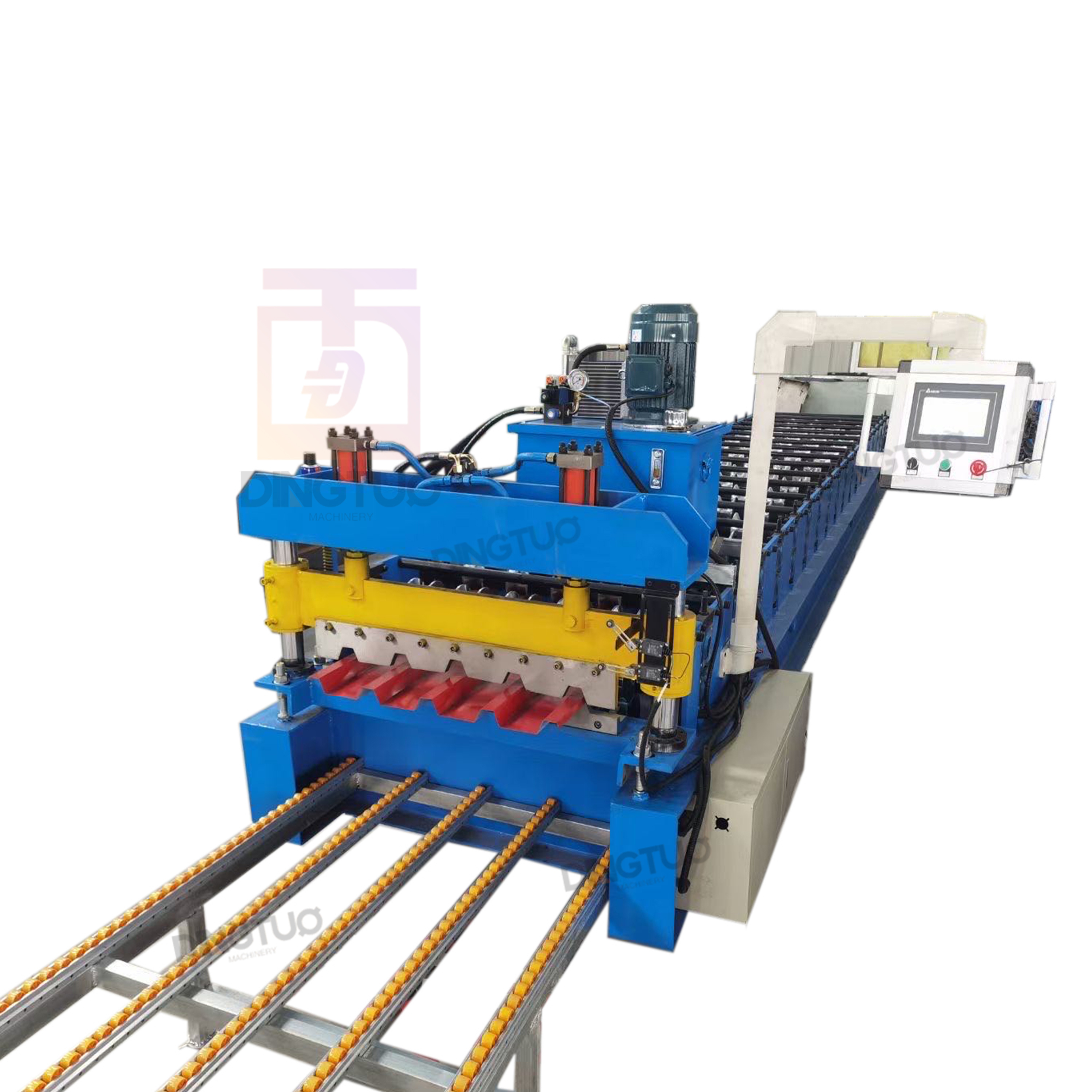

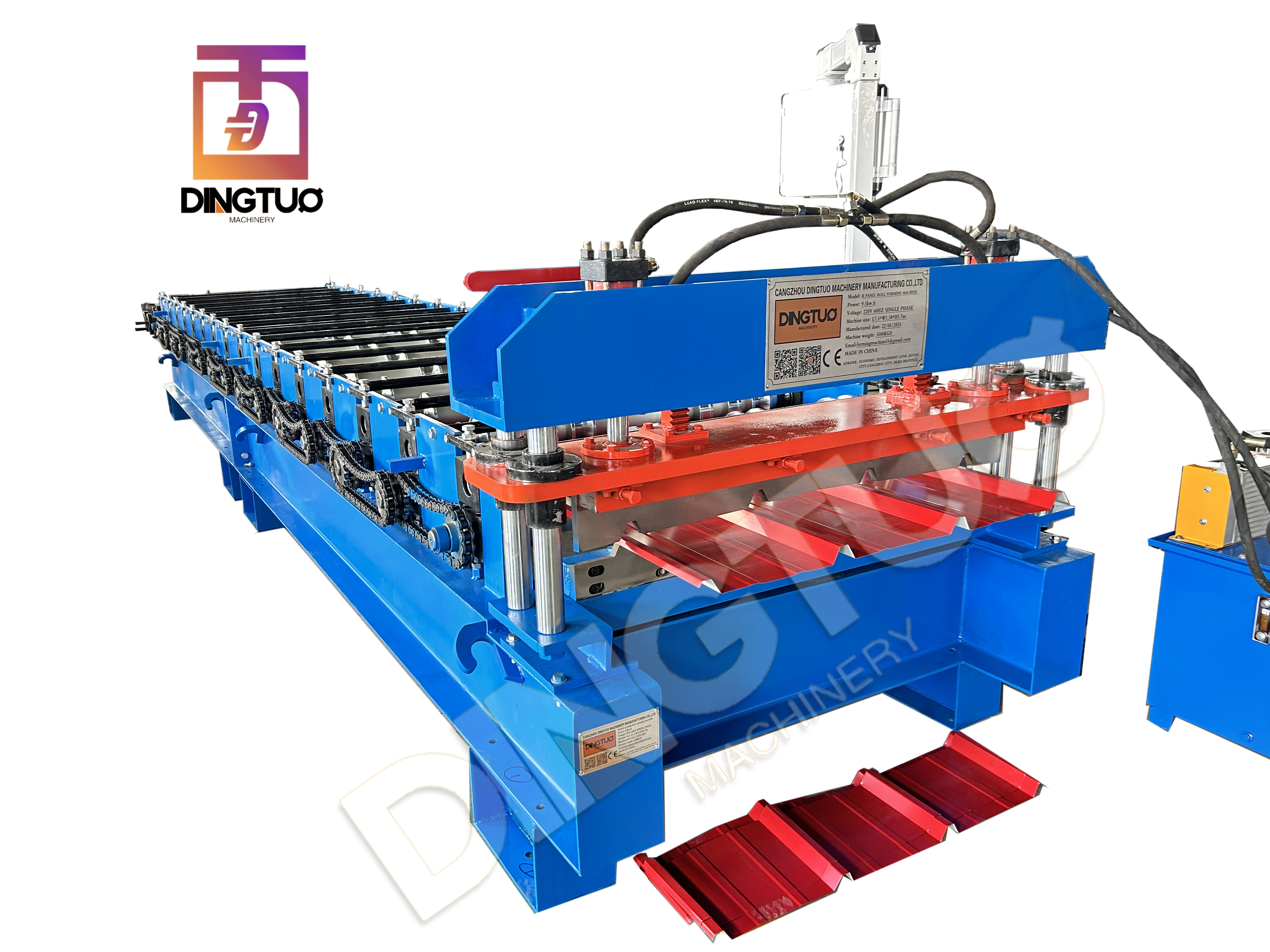

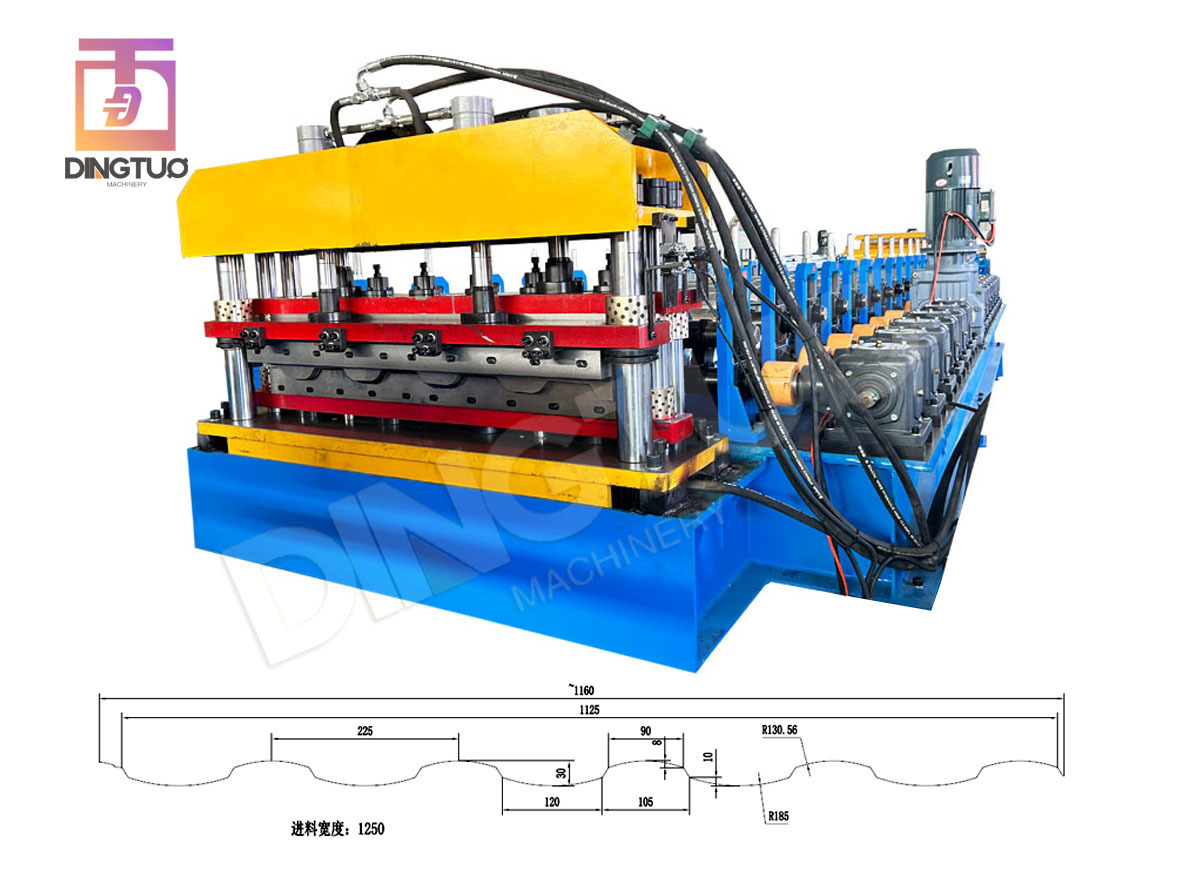

This is a specialized machine designed for the roll forming of metal corrugated roofing sheets. The machine is capable of processing raw materials with a minimum thickness starting at just 0.12mm, which allows for versatility in various roofing applications. Once the production process is complete, the finished corrugated sheets exhibit a flawless surface, completely free of any wrinkles or imperfections. Additionally, the arc shape of the sheets is exceptionally well-formed, exhibiting no rebound, which is crucial for ensuring the structural integrity and aesthetic appeal of the roofing material. The superior quality of the finished product can be attributed to the advanced technology used in the manufacturing of the machine itself. The rollers of this machine are meticulously processed using high-precision CNC (Computer Numerical Control) machine tools. This ensures that every roller is crafted with the utmost care, resulting in optimal smoothness and precision. The high level of accuracy in the roller manufacturing process directly contributes to the quality of the corrugated sheets produced, making this machine an essential asset for any roofing material manufacturer looking to deliver top-notch products to their clients.

MACHINE COMPONENTS

NO. | Description | Quantity (set) |

1 | 5T electric decoiler | 1 |

2 | Feeding Platform | 1 |

3 | Forming System | 1 |

4 | Transmission system | 1 |

5 | Hydraulic cutting system | 1 |

6 | Hydraulic pump station | 1 |

7 | Electric Control Cabinet | 1 |

8 | run out table | 1 |

9 | Spare parts and tools | 1 |

MACHINE PARAMETERS

No | Item | Parameter |

1 | Raw material | G550 GI |

2 | Thickness | 0.12-0.3 mm |

3 | Feeding width/coil width | 914 or customized |

4 | Useful width | 655mm or customized |

5 | Machine stands | 16mm |

6 | Forming Speed | 25-30 m/min |

7 | Forming station | 24 |

8 | Total Power | 7.5 kw (main motor power) + 5.5 KW(hydraulic pump station motor power) |

9 | Mill bed material | 350H beams welded |

10 | Voltage | 380 V , 50HZ, 3 Phases or customized |

11 | Diameter of shaft | 70mm diameter solid shafts ( fine grinding) |

12 | Cutting type | 4 pillar guides |

13 | Forming Shaft | 45# steel with grinding process |

14 | Forming Roller | 45# steel with hard chrome |

15 | Cutting Blade | Cr12 with hard treatment |

16 | Transmission | 1 inch chain double row |

17 | PLC | DELTA Brands /MITSUBISHI |

18 | Touch Screen | DELTA Brand/MITSUBISHI |

19 | Electrical motor | SHANGHAI BOJIANG brand |

20 | Encoder | OMRON Brand with aluminum bracket |

21 | Low-voltage electrical | SCHNEIDER Brands |

22 | Host Machine rough size | L11m*W2m*H2.2m |

23 | Host Machine rough weight | 6500KGS |

24 | Machine with Anchor bolts | Have |

25 | Run Out Table | have |

MACHINE DETAILS

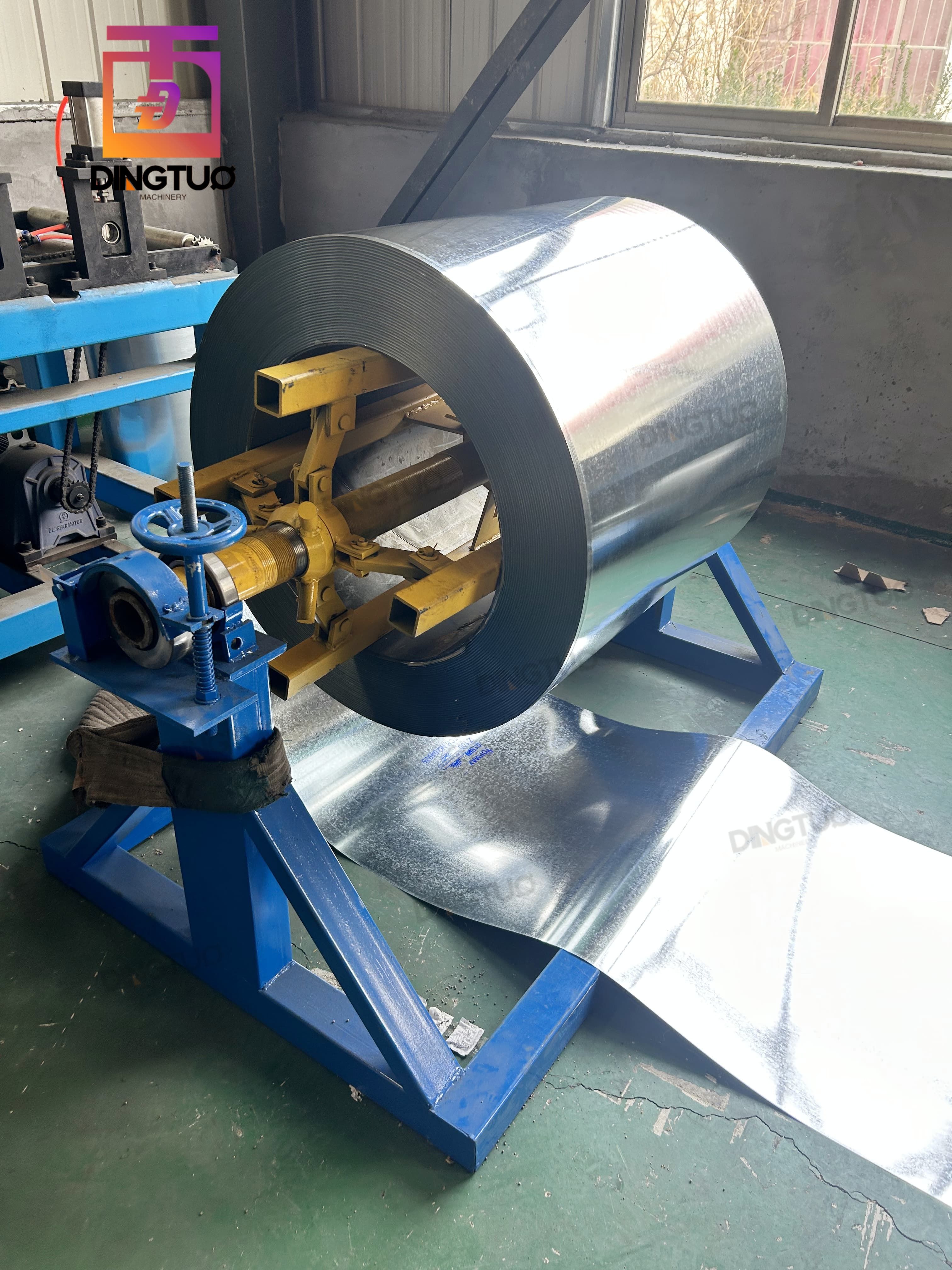

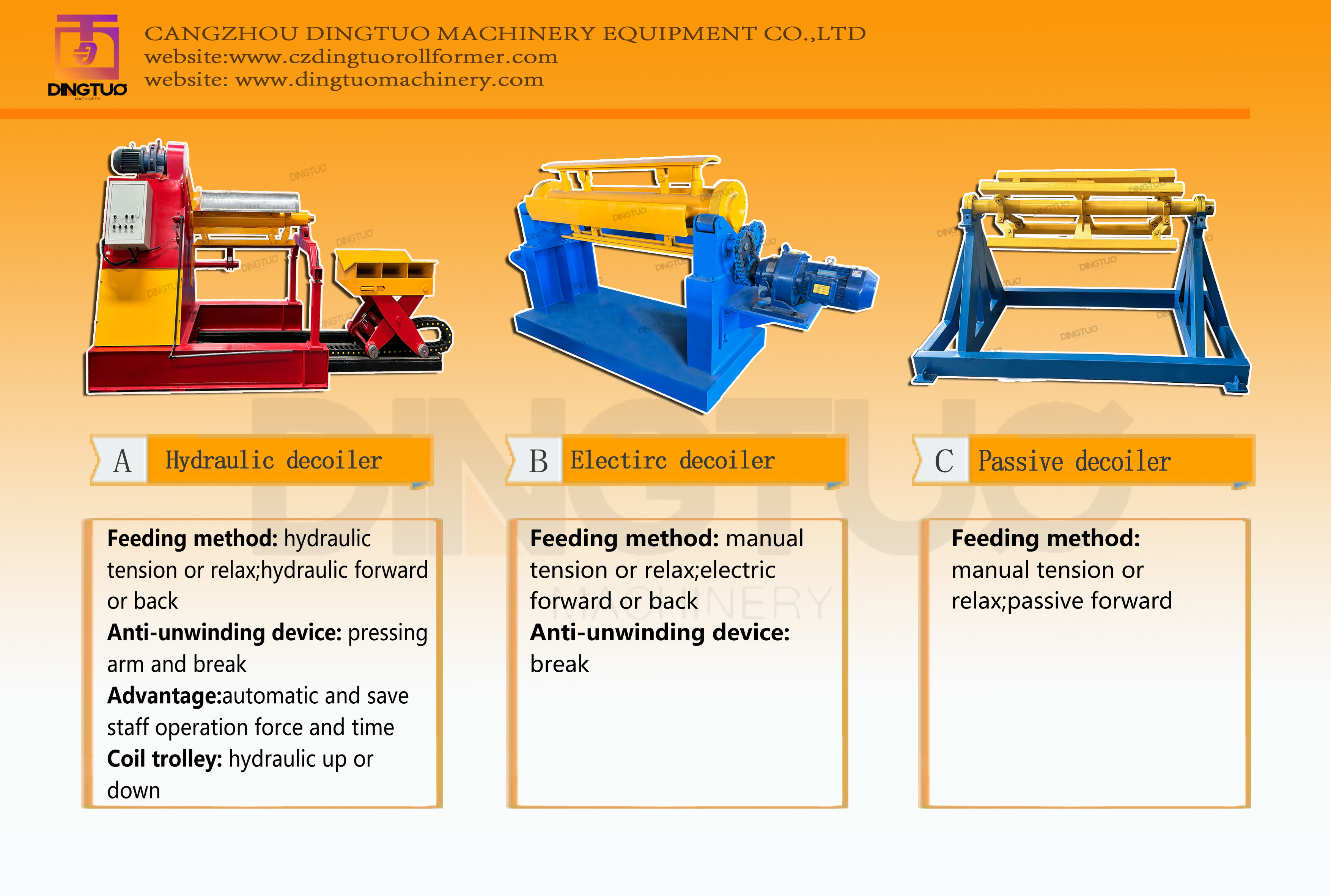

1.DECOILER

2. FORMING MACHINE

3. MACHINE RUN OUT TABLE

No. | Name | Quantity | Country |

1 | Rely | several | China |

2 | Encoder | 1pcs | China |

3 | Encoder wheels | 2pcs | China |

4 | bearings | 2pcs | China |

5 | Travelling Buttons | 2pcs | China |

6 | Switch buttons | 3pcs | China |

7 | The electromagnetic valve | 1pcs | China |

8 | Oil tubes | 2pcs | China |

9 | Gears | 2pcs | China |

10 | Chains | 2meters | China |

11 | circlip | Several | China |

12 | Tool Box | 1 Set | China |

Upgrade your roofing production with our quality metal self lock roofing sheet roll forming machine – engineered to deliver flawless, high-strength roofing sheets with secure interlocking edges. Designed for manufacturers seeking durability, efficiency, and precision, this machine ensures weatherproof, leak-resistant panels perfect for industrial, commercial, and residential applications.

Why Choose Our Machine?

✔ Self-Locking Technology – Produces interlocking roofing sheets that snap tightly together, eliminating gaps and enhancing structural integrity.

✔ Heavy-Duty Performance – Constructed with high-grade steel and hardened rollers for long-lasting operation, even under continuous use.

✔ Customizable Profiles – Adjustable roll-forming system supports multiple sheet designs (trapezoidal, standing seam, etc.) to meet diverse project needs.

✔ High-Speed Production – Automated PLC control enables fast output (15-30m/min) while maintaining consistent thickness and accuracy.

✔ Low Maintenance & Energy Efficient – Optimized design reduces downtime and power consumption, maximizing ROI.

Invest in a quality metal self lock roofing sheet roll forming machine that guarantees smooth operation, minimal waste, and superior corrosion-resistant panels. Trusted by global manufacturers, our machine combines advanced engineering with cost-effective production.

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat