High speed double layer roofing sheet roll forming machine with double layer automatic stacker

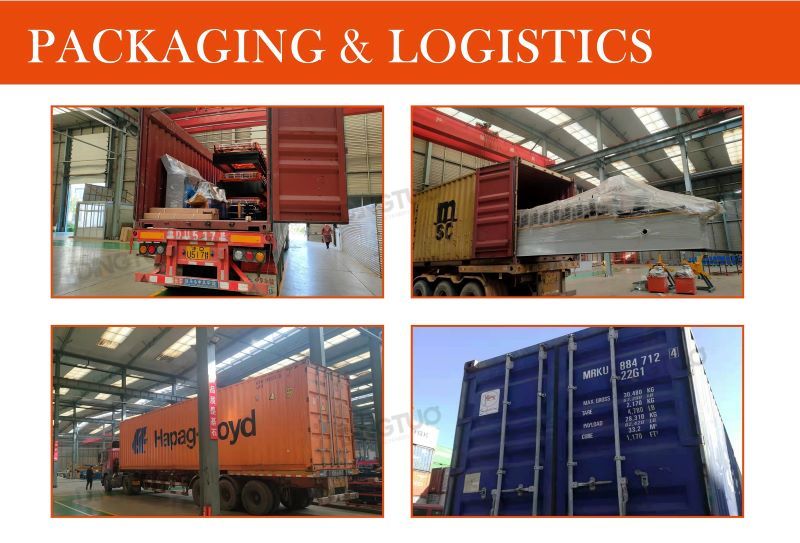

Key words:

Product category:

Tel/Whatsapp:

High speed double layer roofing sheet roll forming machine with double layer automatic stacker

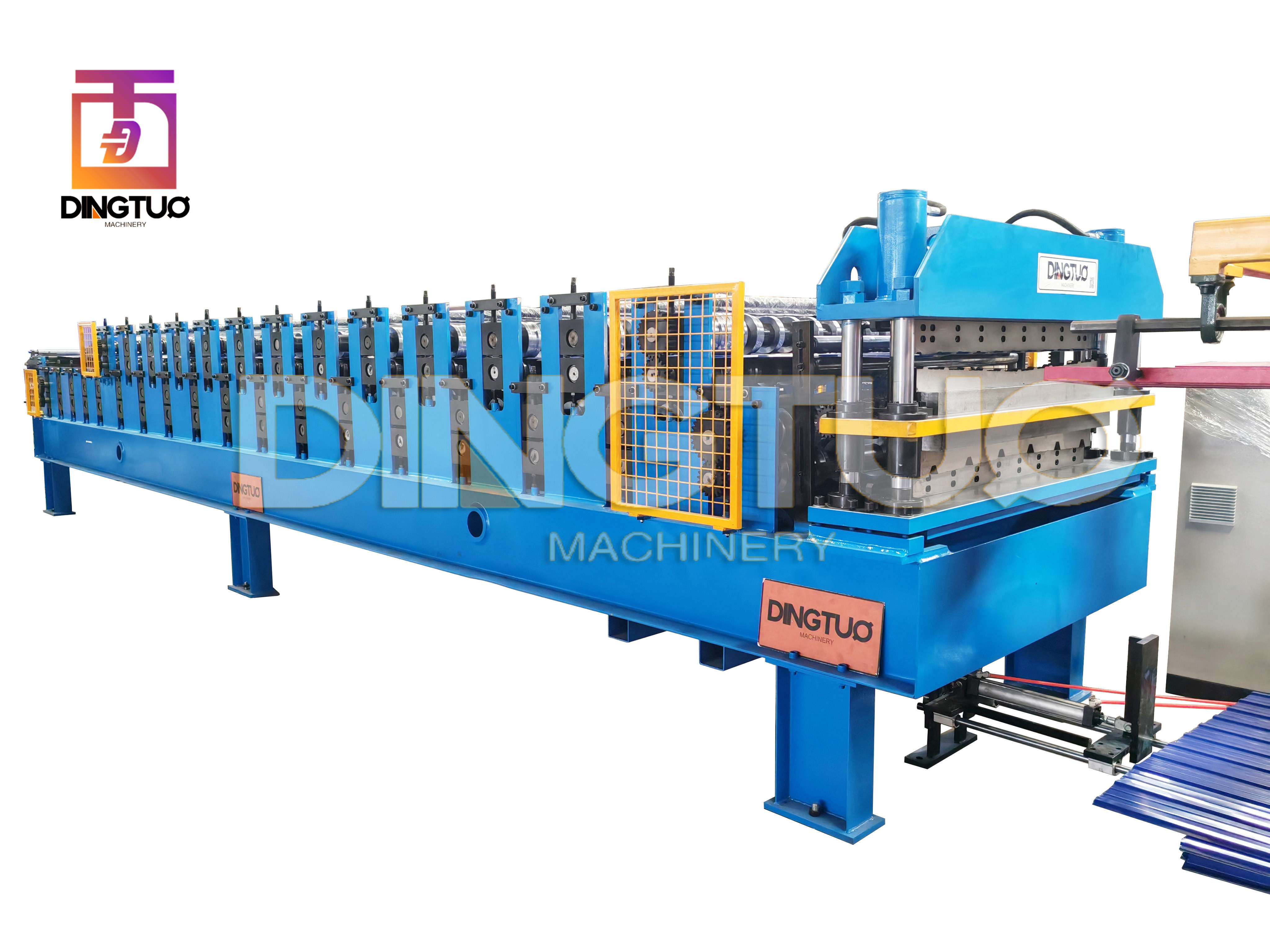

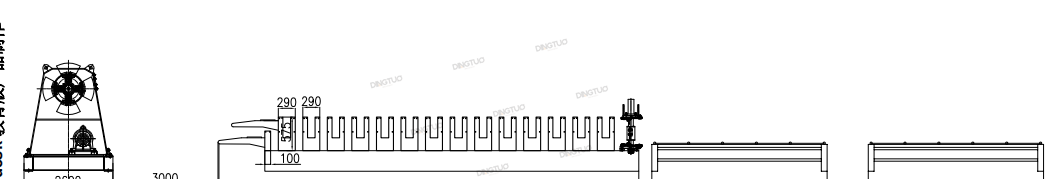

Machine Introduction And Schematic

The high-speed double layer roofing sheet roll forming machine is engineered with advanced technology that allows for the simultaneous production of two distinct types of roofing sheets, significantly reducing manufacturing time and costs. This dual-layer capability not only maximizes the utility of raw materials but also caters to the diverse aesthetic and functional requirements of various construction projects. Additionally, the machine's automatic stacker ensures that finished products are neatly organized and readily available for dispatch, minimizing manual handling and reducing labor costs. With adjustable settings, operators can easily switch between different profiles and thicknesses, making it ideal for both small-scale builders and large construction firms. The robust design of the machine ensures durability and reliability, capable of withstanding the rigors of continuous operation. Furthermore, its energy-efficient features contribute to lower operational costs, aligning with the industry's push towards sustainable practices. As the demand for high-quality roofing solutions continues to grow, investing in such advanced machinery not only enhances a company's competitive edge but also contributes to the overall improvement of building standards in the market. Ultimately, the high-speed double layer roofing sheet roll forming machine represents a pivotal innovation that addresses the pressing needs of the construction sector, paving the way for smarter, more efficient building solutions.

NO. | Description | Quantity (set) |

1 | 5T hydraulic decoiler with coil car | 1 |

2 | Feeding Platform | 1 |

3 | Forming System | 1 |

4 | Transmission system | 1 |

5 | Hydraulic cutting system | 1 |

6 | Hydraulic pump station | 1 |

7 | Electric Control Cabinet | 1 |

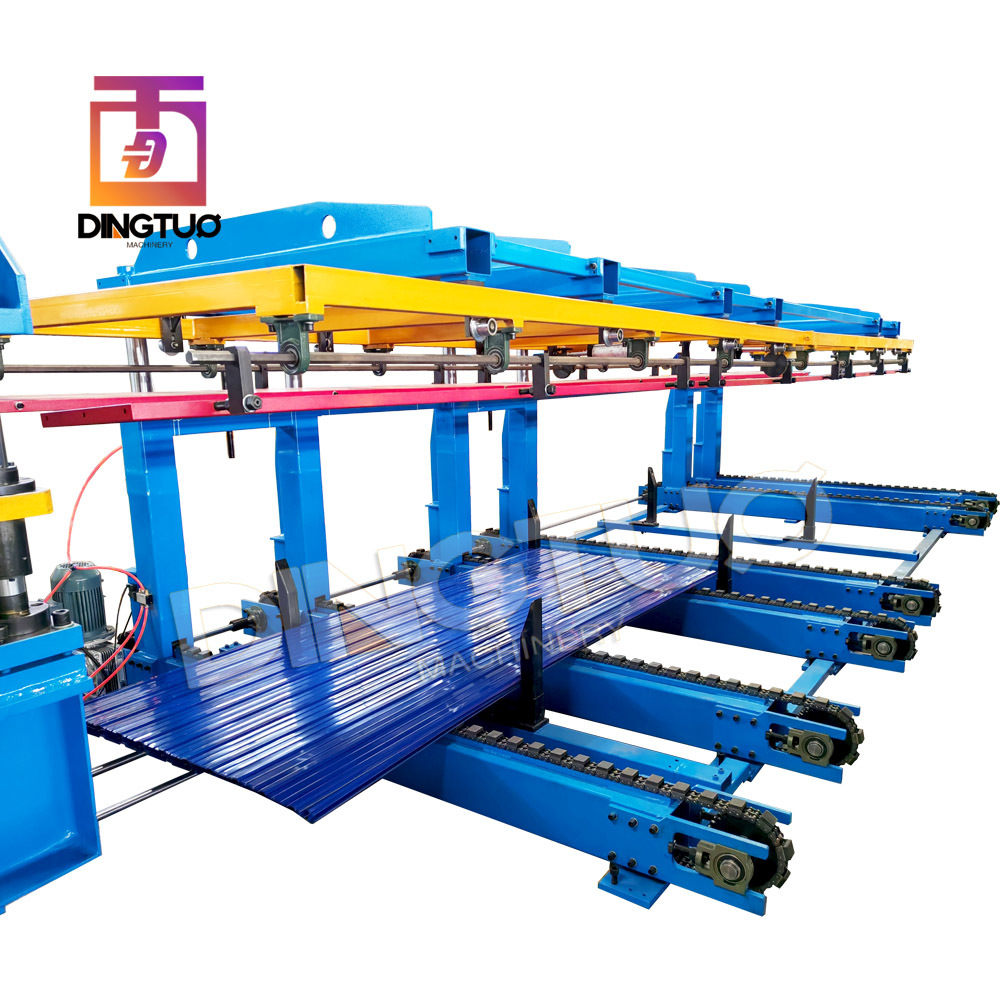

8 | Automatic stacker | 6m |

9 | Spare parts and tools | 1 |

Machine Parameter

No | Item | Parameter |

1 | Raw material | PPGI |

2 | Thickness | 0.3-0.8 mm |

3 | Feeding width/coil width | 41 inch or customized |

4 | Useful width | 36 inch |

5 | Machine stands | iron plates welded |

6 | Forming Speed | 20 m/min |

| 7 | Forming station | 22 |

| 8 | Total Power | 11 kw (main motor power) + 7.5 KW(hydraulic pump station motor power) |

9 | Mill bed material | 400H beams welded |

10 | Voltage | 380 V , 50HZ, 3 Phases |

11 | Diameter of shaft | 75mm diameter solid shafts |

12 | Cutting type | 4 pillar guides |

13 | Forming Shaft | 45# steel with grinding process |

14 | Forming Roller | 45# steel with hard chrome coating process and overall quenching or customized Gcr15 bearing steel material |

15 | Cutting Blade | Cr12 with hard treatment |

16 | Transmission | 1 inch chain double row |

17 | PLC | DELTA Brands /MITSUBISHI |

18 | Touch Screen | DELTA Brand/MITSUBISHI |

19 | Electrical motor | SHANGHAI BOJIANG brand |

20 | Encoder | OMRON Brand with aluminum bracket |

21 | Low-voltage electrical | SCHNEIDER Brands |

22 | Host Machine rough size | L11m*W2m*H2.2m |

23 | Host Machine rough weight | 15000KGS |

24 | Machine with Anchor bolts | Have |

| 25 | Automatic Stacker | 6m long double deck |

7 Tons X 1250mm Wide Hydraulic Decoiler With Coil Car

6m Double Layer Liftable Auto Stacker : speed fast and liftable stability

Spare Part

No. | Name | Quantity | Country |

1 | Rely | several | China |

2 | Encoder | 1pcs | China |

3 | Encoder wheels | 2pcs | China |

4 | bearings | 2pcs | China |

5 | Travelling Buttons | 2pcs | China |

6 | Switch buttons | 3pcs | China |

7 | The electromagnetic valve | 1pcs | China |

8 | Oil tubes | 2pcs | China |

9 | Gears | 2pcs | China |

10 | Chains | 2meters | China |

11 | circlip | Several | China |

12 | Tool Box | 1 Set | China |

Upgrade your roofing production with our quality metal self lock roofing sheet roll forming machine – engineered to deliver flawless, high-strength roofing sheets with secure interlocking edges. Designed for manufacturers seeking durability, efficiency, and precision, this machine ensures weatherproof, leak-resistant panels perfect for industrial, commercial, and residential applications.

Why Choose Our Machine?

✔ Self-Locking Technology – Produces interlocking roofing sheets that snap tightly together, eliminating gaps and enhancing structural integrity.

✔ Heavy-Duty Performance – Constructed with high-grade steel and hardened rollers for long-lasting operation, even under continuous use.

✔ Customizable Profiles – Adjustable roll-forming system supports multiple sheet designs (trapezoidal, standing seam, etc.) to meet diverse project needs.

✔ High-Speed Production – Automated PLC control enables fast output (15-30m/min) while maintaining consistent thickness and accuracy.

✔ Low Maintenance & Energy Efficient – Optimized design reduces downtime and power consumption, maximizing ROI.

Invest in a quality metal self lock roofing sheet roll forming machine that guarantees smooth operation, minimal waste, and superior corrosion-resistant panels. Trusted by global manufacturers, our machine combines advanced engineering with cost-effective production.

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat