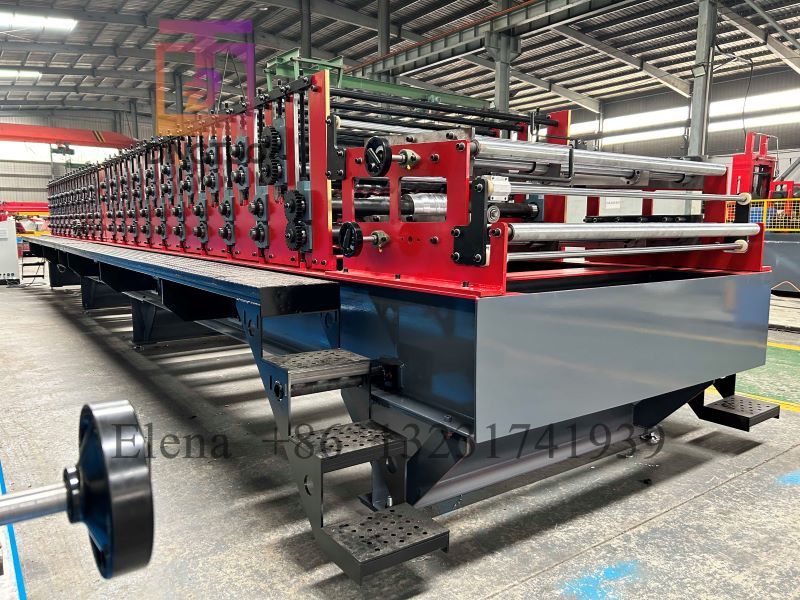

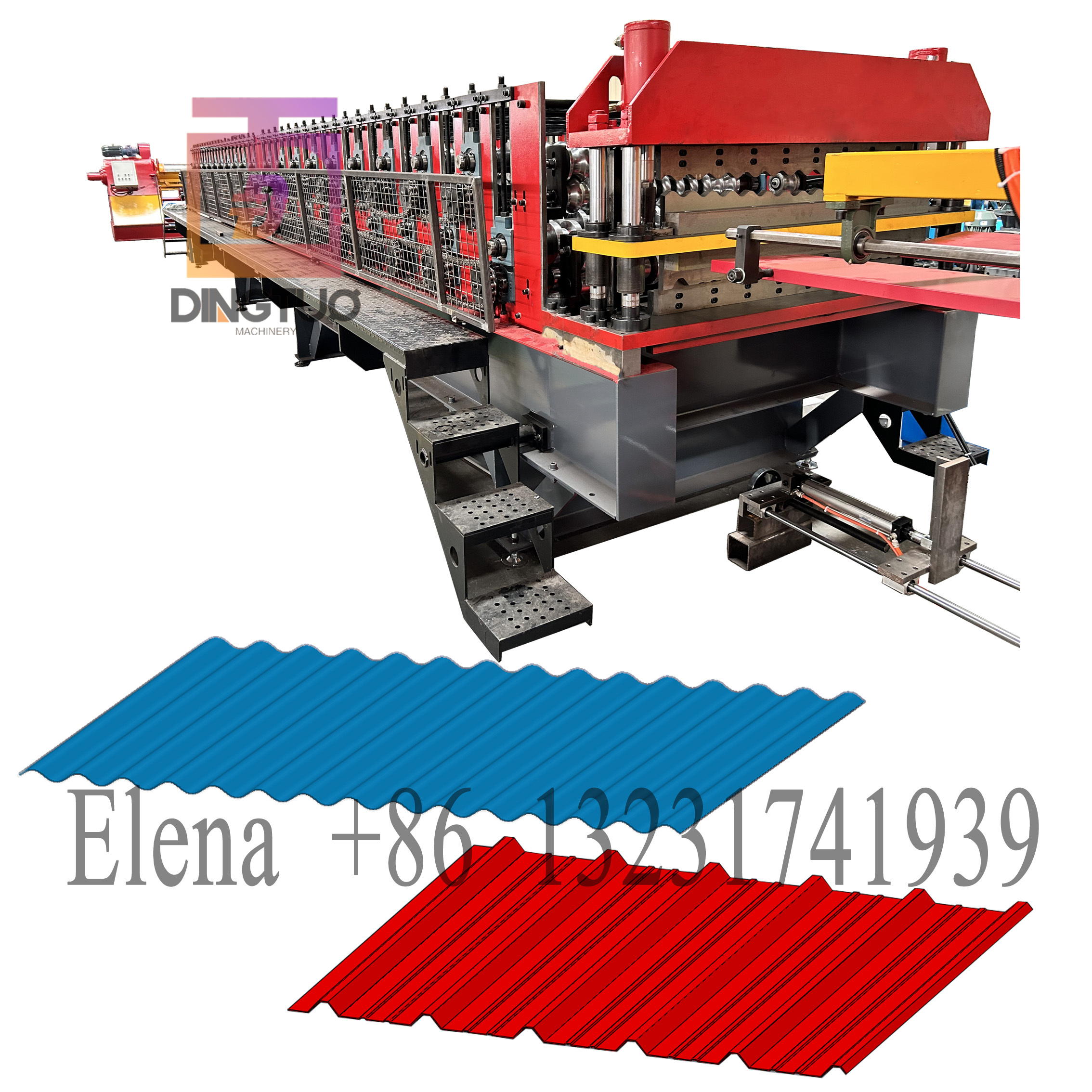

Full automatic double layer roll forming machine with auto stacker

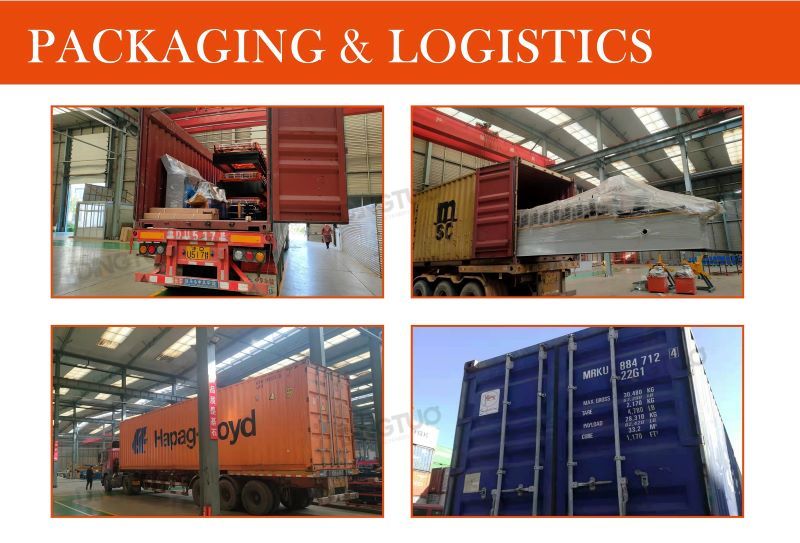

Key words:

Product category:

Tel/Whatsapp:

Full automatic double layer roll forming machine with auto stacker

Profile Drawing

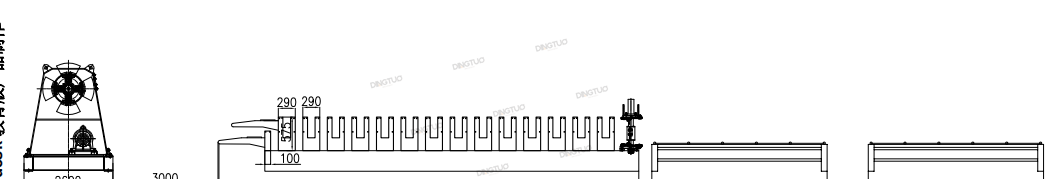

Machine Schematic

NO. | Description | Quantity (set) |

1 | 5T hydraulic decoiler with coil car | 1 |

2 | Feeding Platform | 1 |

3 | Forming System | 1 |

4 | Transmission system | 1 |

5 | Hydraulic cutting system | 1 |

6 | Hydraulic pump station | 1 |

7 | Electric Control Cabinet | 1 |

8 | Automatic stacker | 6m |

9 | Spare parts and tools | 1 |

Machine Parameter

No | Item | Parameter |

1 | Raw material | PPGI |

2 | Thickness | 0.3-0.8 mm |

3 | Feeding width/coil width | 41 inch or customized |

4 | Useful width | 36 inch |

5 | Machine stands | iron plates welded |

6 | Forming Speed | 20 m/min |

| 7 | Forming station | 22 |

| 8 | Total Power | 11 kw (main motor power) + 7.5 KW(hydraulic pump station motor power) |

9 | Mill bed material | 400H beams welded |

10 | Voltage | 380 V , 50HZ, 3 Phases |

11 | Diameter of shaft | 75mm diameter solid shafts |

12 | Cutting type | 4 pillar guides |

13 | Forming Shaft | 45# steel with grinding process |

14 | Forming Roller | 45# steel with hard chrome coating process and overall quenching or customized Gcr15 bearing steel material |

15 | Cutting Blade | Cr12 with hard treatment |

16 | Transmission | 1 inch chain double row |

17 | PLC | DELTA Brands /MITSUBISHI |

18 | Touch Screen | DELTA Brand/MITSUBISHI |

19 | Electrical motor | SHANGHAI BOJIANG brand |

20 | Encoder | OMRON Brand with aluminum bracket |

21 | Low-voltage electrical | SCHNEIDER Brands |

22 | Host Machine rough size | L11m*W2m*H2.2m |

23 | Host Machine rough weight | 15000KGS |

24 | Machine with Anchor bolts | Have |

| 25 | Automatic Stacker | 6m long double deck |

6m Auto Stacker For The Double Layer Machine

NO. | ITEM | SPECIFICATION |

1 | Receiving Sheet Sizes | Length:1.5 to 6m; Width:within 1.25m |

2 | Receiving And Unwinding Type | the cylinder is used to pull the receiving and unwinding, and the receiving plate can be moved vertically 500mm |

3 | Motor Power Of Feeding Table | 2.2kw Lichao brand motor, RV reducer. |

4 | Receiving Drum Material And Feeding Drum Material | The receiving drum adopts stainless steel drum; the outer surface of the feeding drum is plated with hard chromium. |

5 | Stacker Sizes | L6m*2.6m |

6 | The main machine moves up and down travel | The stacker can pick up the material in two layers, up and down 400mm |

7 | The main machine release board is assembled by manual stabilizing board. | |

8 | Pneumatic pusher is added before and after the main machine puts the board. | |

9 | Receiving Material Speed | Max. 25m/min |

Spare Part

No. | Name | Quantity | Country |

1 | Rely | several | China |

2 | Encoder | 1pcs | China |

3 | Encoder wheels | 2pcs | China |

4 | bearings | 2pcs | China |

5 | Travelling Buttons | 2pcs | China |

6 | Switch buttons | 3pcs | China |

7 | The electromagnetic valve | 1pcs | China |

8 | Oil tubes | 2pcs | China |

9 | Gears | 2pcs | China |

10 | Chains | 2meters | China |

11 | circlip | Several | China |

12 | Tool Box | 1 Set | China |

Recommend Products

Product Consulting

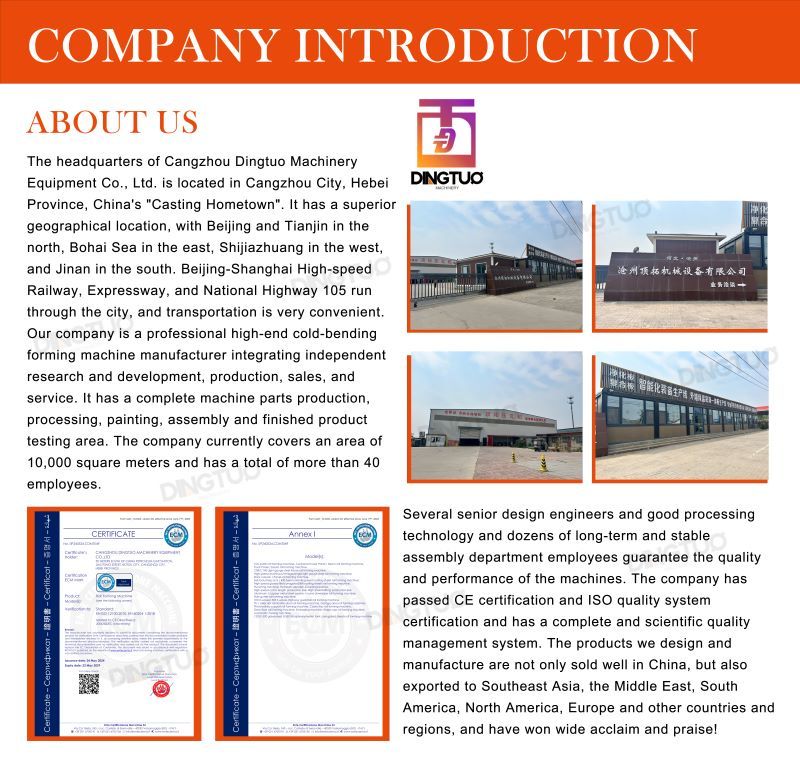

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat