PBR & R panel roll forming machine

Key words:

Product category:

Tel/Whatsapp:

PBR & R panel roll forming machine

RELATED MACHINES

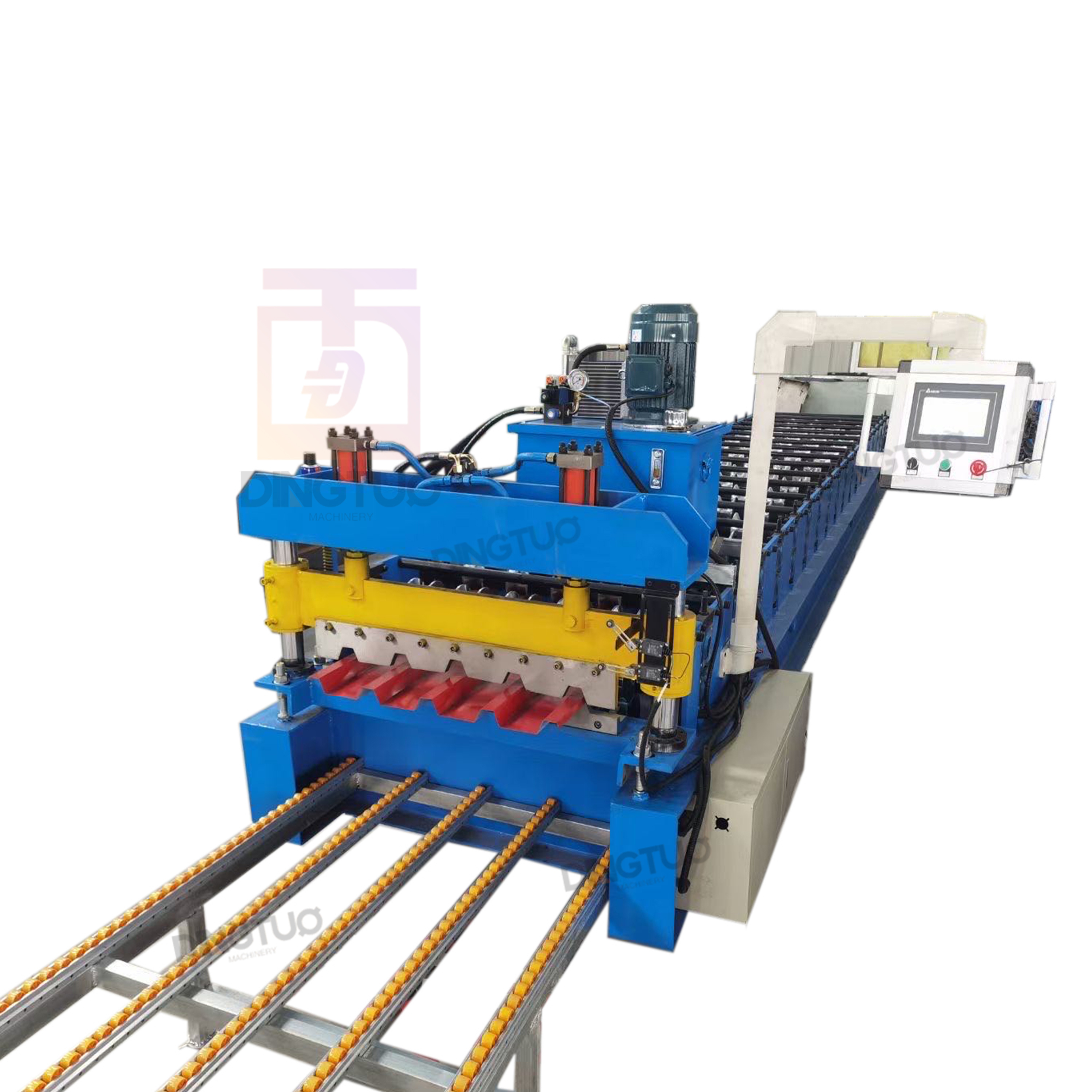

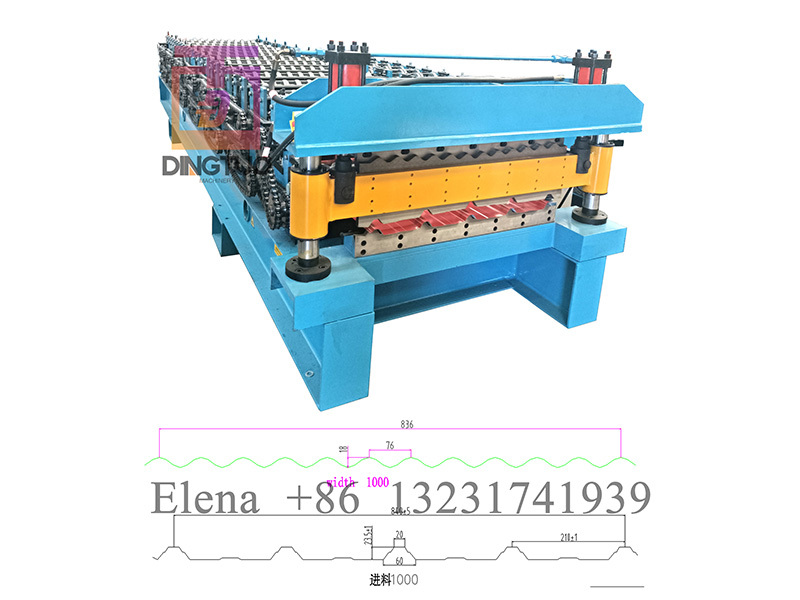

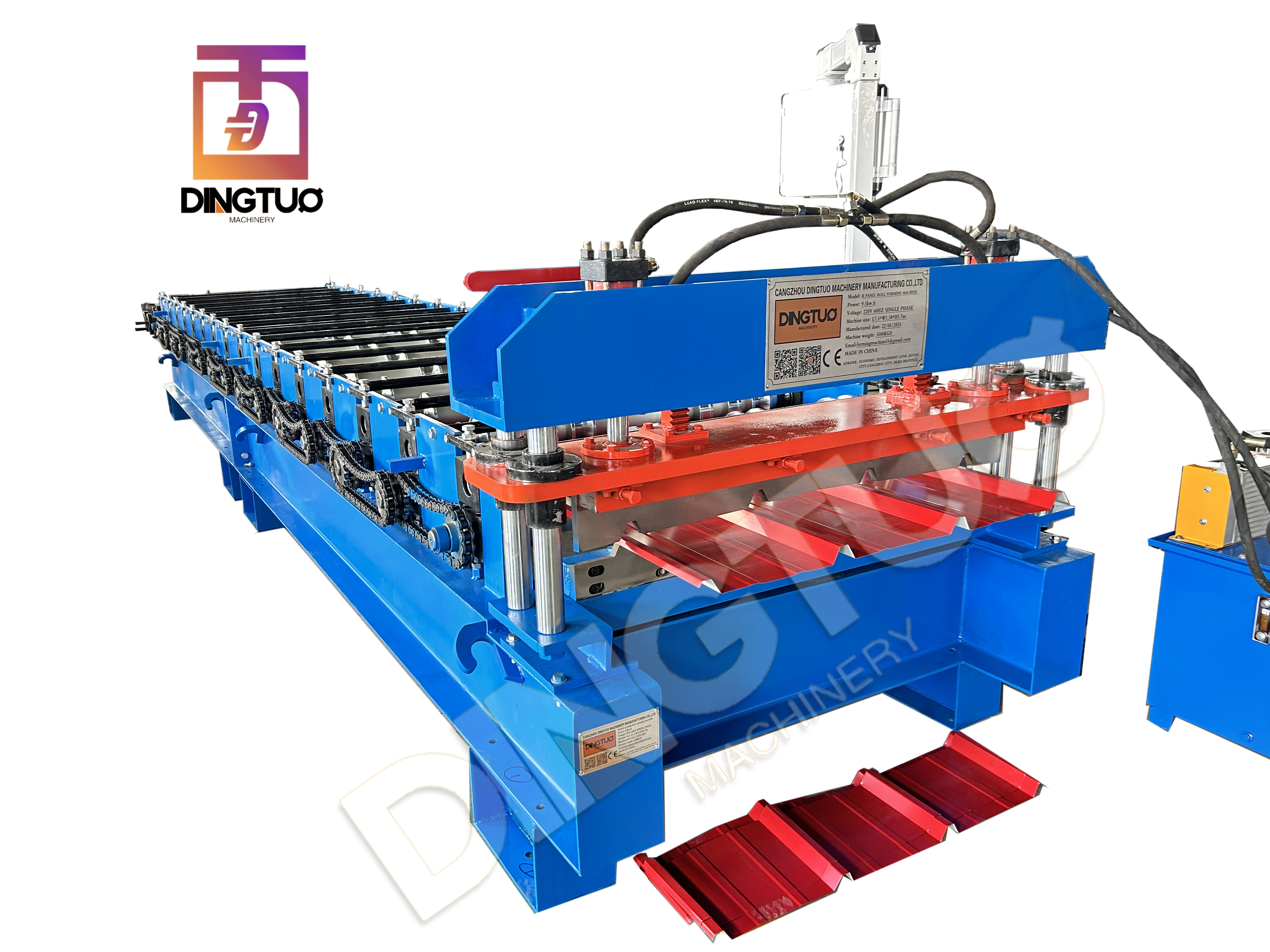

METAL PBR & R ROOF PANEL ROLL FORMING MACHINE

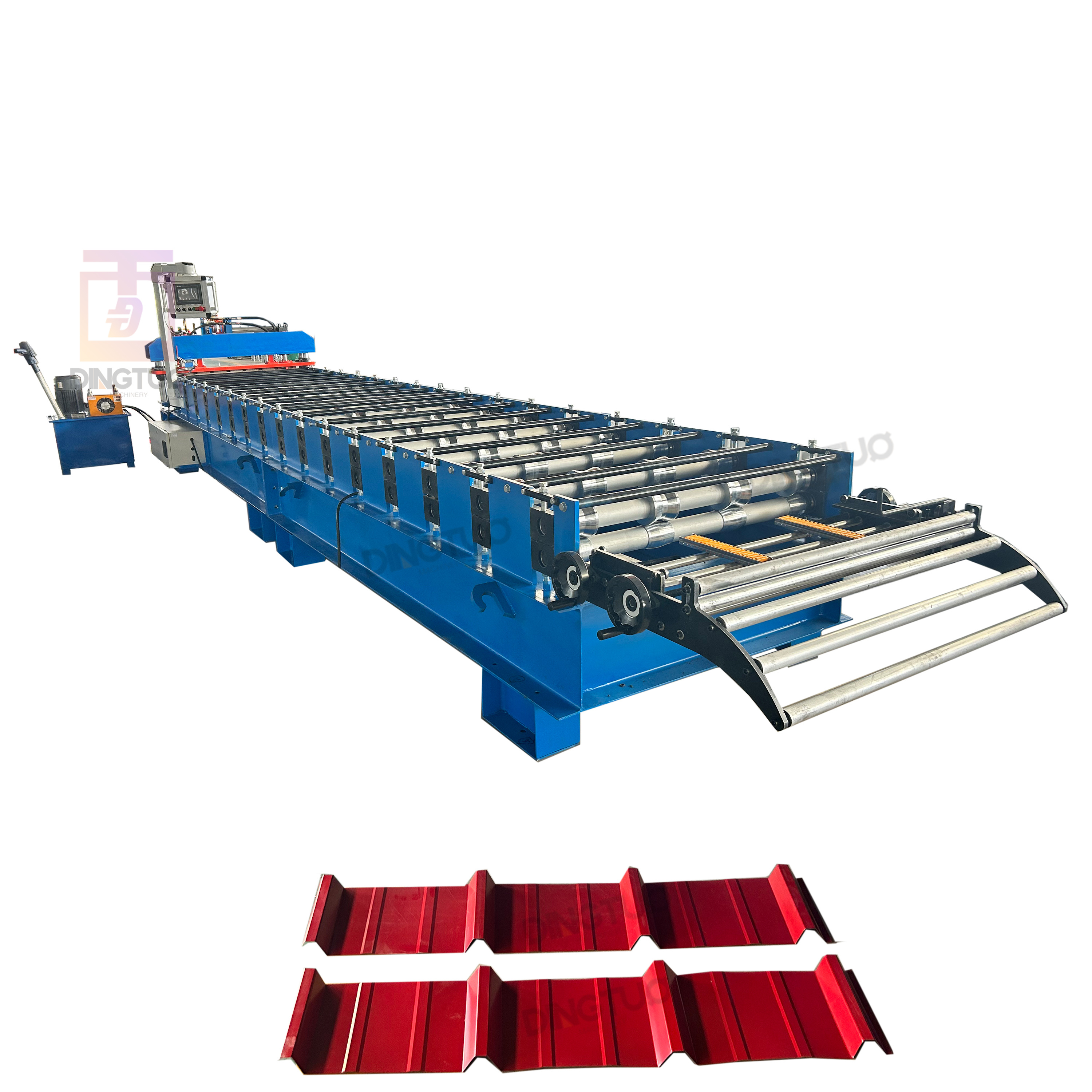

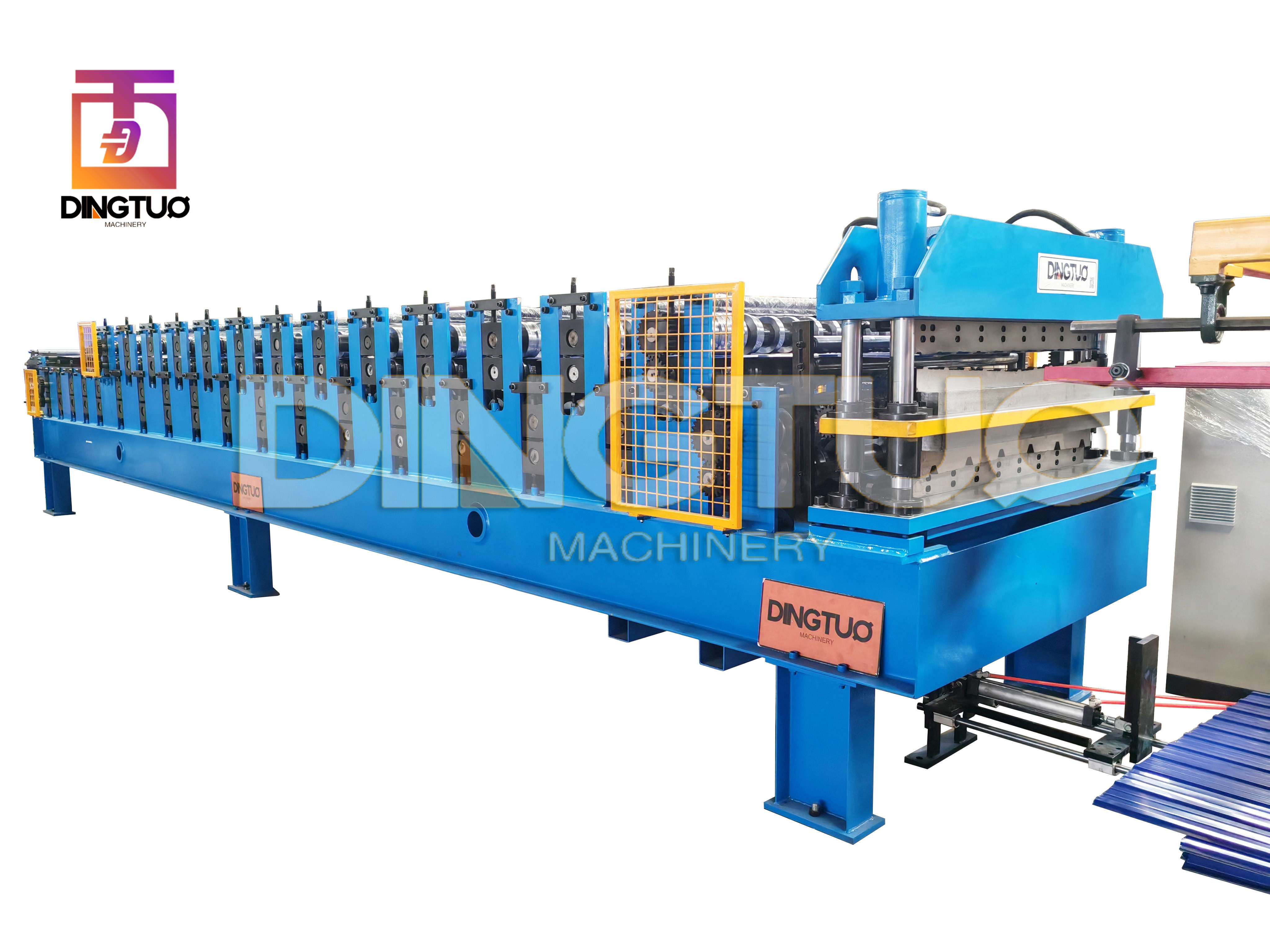

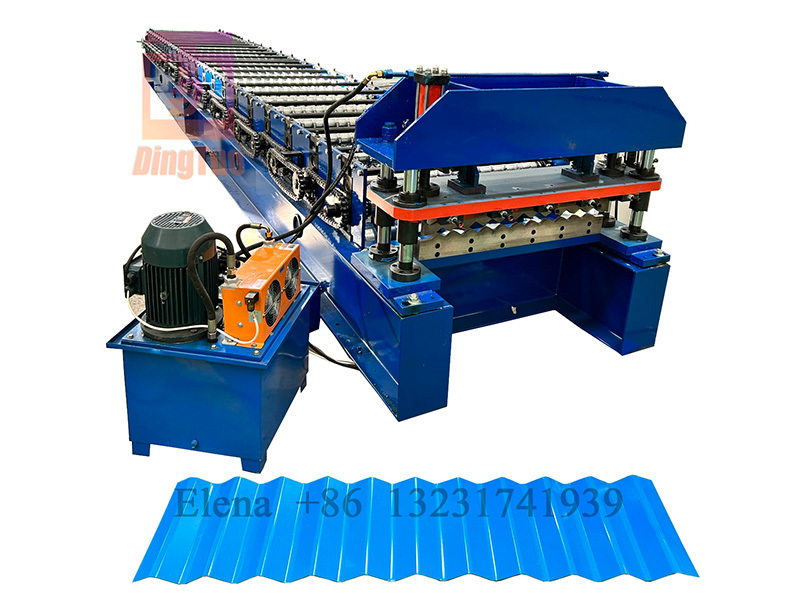

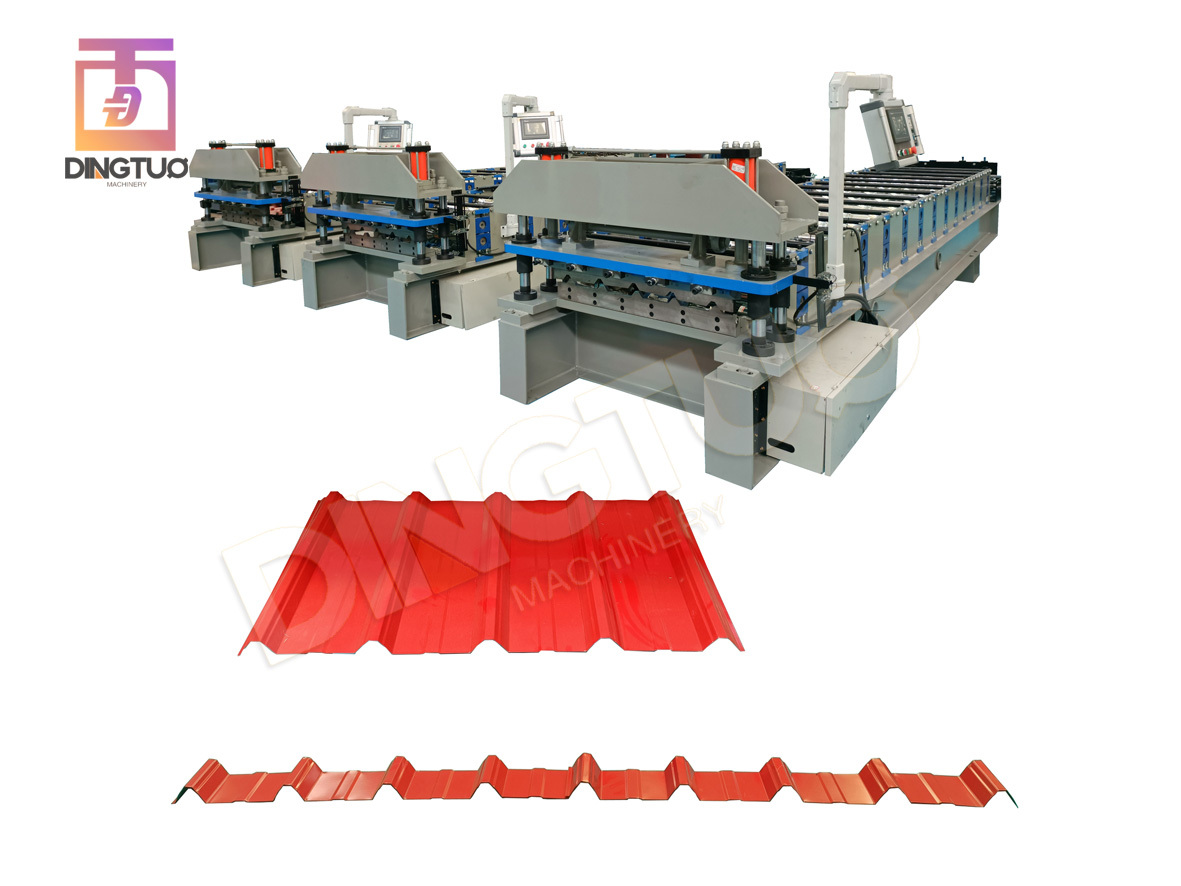

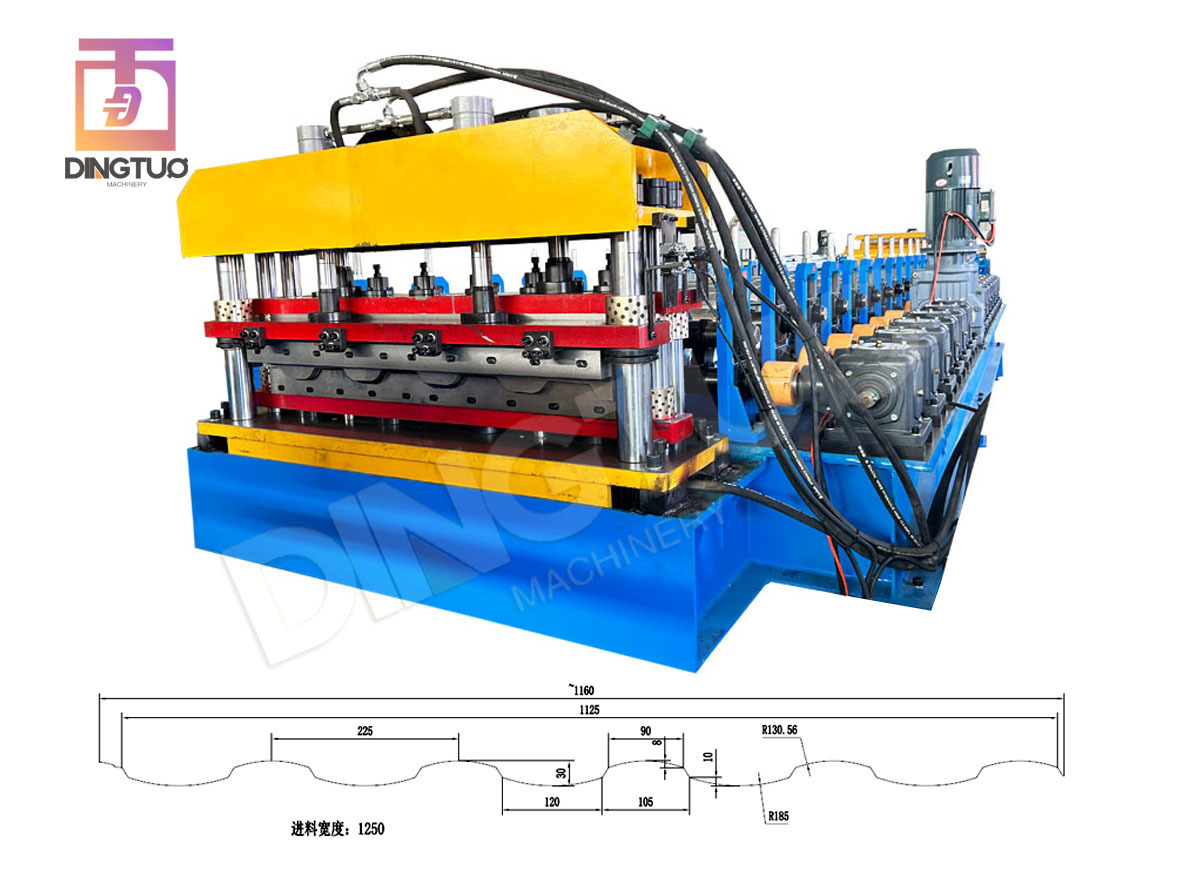

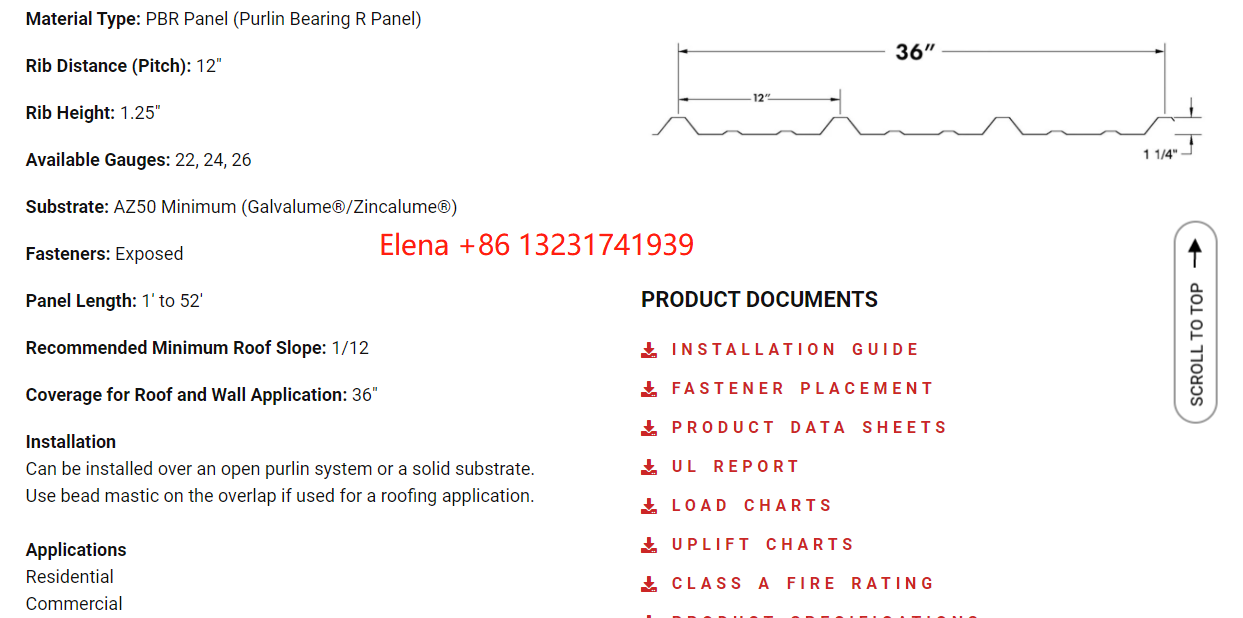

This is a highly efficient metal PBR roof panel roll forming machine designed to meet the needs of the roofing industry. The machine is engineered to handle raw materials with a width of 43 inches, ensuring that it can accommodate a variety of metal sheets. The effective width of the roof panels produced by this machine measures 36 inches, which is ideal for creating robust and durable roofing solutions. These metal sheets have gained immense popularity across the United States, thanks to their strength and aesthetic appeal. The machine is capable of working with sheet gauges ranging from 20 gauge to 22 gauge, providing versatility in production options. Additionally, the structure of the machine supports customization, allowing manufacturers to tailor the equipment to their specific production requirements and preferences. This flexibility ensures that users can optimize their workflow and produce high-quality roofing panels that meet diverse market demands.

- Machine Outlet

NO. | Description | Quantity (set) | Remark |

1 | 5T manual decoiler | 1 |

|

2 | Feeding Platform | 1 | One complete unit as main machine |

3 | Forming System | 1 | |

4 | Transmission system | 1 | |

5 | Hydraulic Cutting System | 1 | |

6 | Run-out table | 1 |

|

7 | Hydraulic pump station | 1 |

|

8 | Electric Control Cabinet | 1 |

|

9 | Spare parts and tools | 1 | As attaching list |

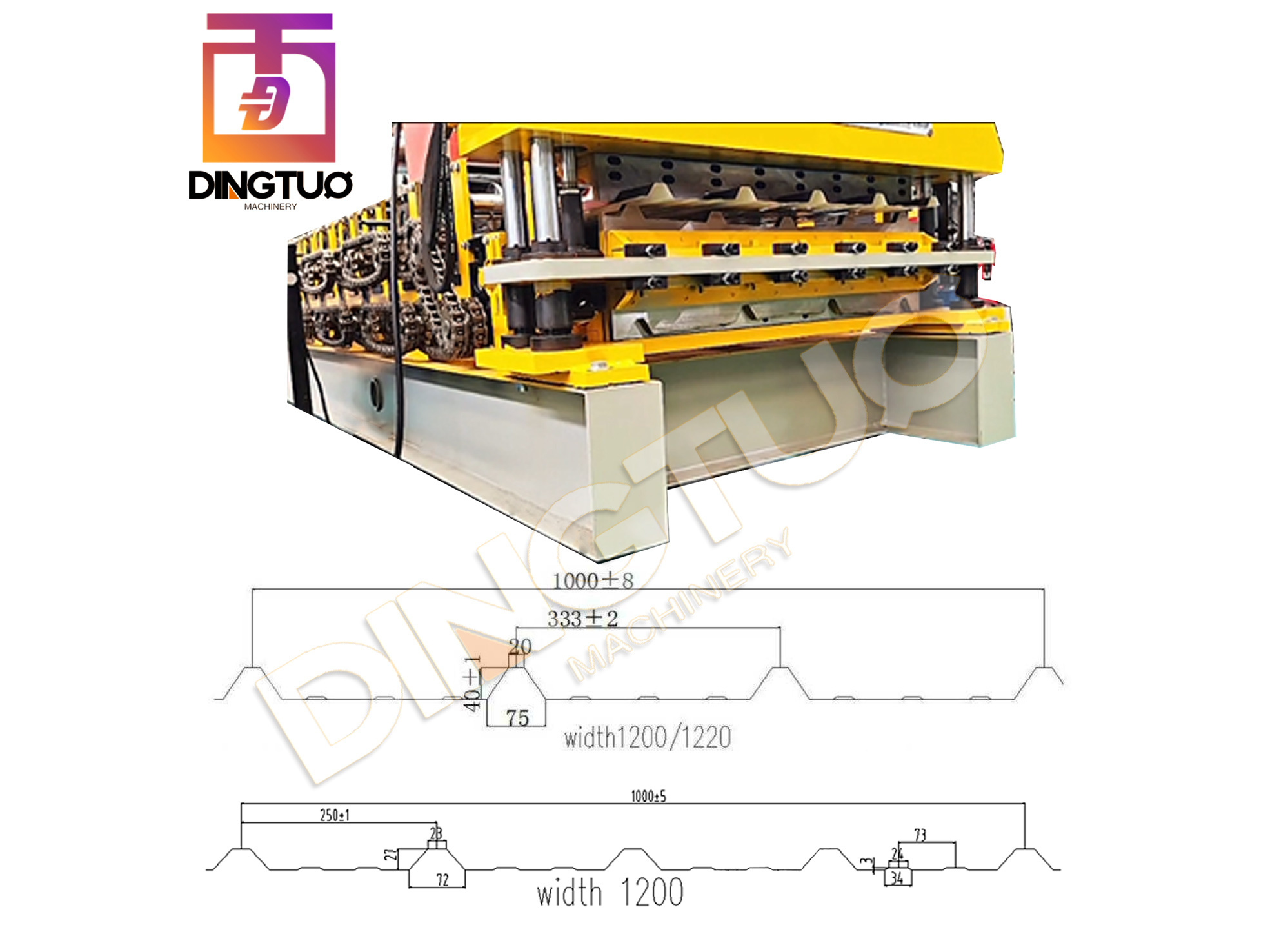

Machine Parameters

No | Item | Parameter |

1 | Raw material | PPGI |

2 | Thickness | 0.3-0.6mm |

3 | Feeding width/coil width | 1092 mm (43 inch ) |

4 | Useful width | 914 mm ( 36 inch ) |

5 | Side stands’ thickness | 16mm |

6 | Forming Speed | 15m/min |

7 | Forming station | 16 stations |

8 | Total Power | 5.5 kw (main motor power) +4 KW(hydraulic pump station motor power) |

9 | Mill bed material | 350H beams welded ,8mm standard H beams’ thick |

10 | Voltage | 380 V , 50HZ, 3 Phases |

11 | Diameter of shaft | 70mm diameter solid shafts |

12 | Cutting type | Automatic hydraulic cutting with iron cast knife holder |

13 | Forming Shaft | 45# steel with grinding process |

14 | Forming Roller | 45# steel with hard chrome coating |

15 | Cutting Blade | Cr12 with hard treatment |

16 | Chain size | One inch |

17 | PLC | DELTA Brands |

18 | Frequency /Touch Screen | DELTA Brand |

19 | Electrical motor | SHANGHAI LICHAO brand |

20 | Encoder | OMRON Brand with aluminum bracket |

21 | Low-voltage electrical | SCHNEIDER Brands |

22 | Machine rough size | L7.5 m*W1.3m*H1.5m |

23 | Machine rough weight | 4.5 tons |

24 | Machine with legs | Have which can level the machine on the ground |

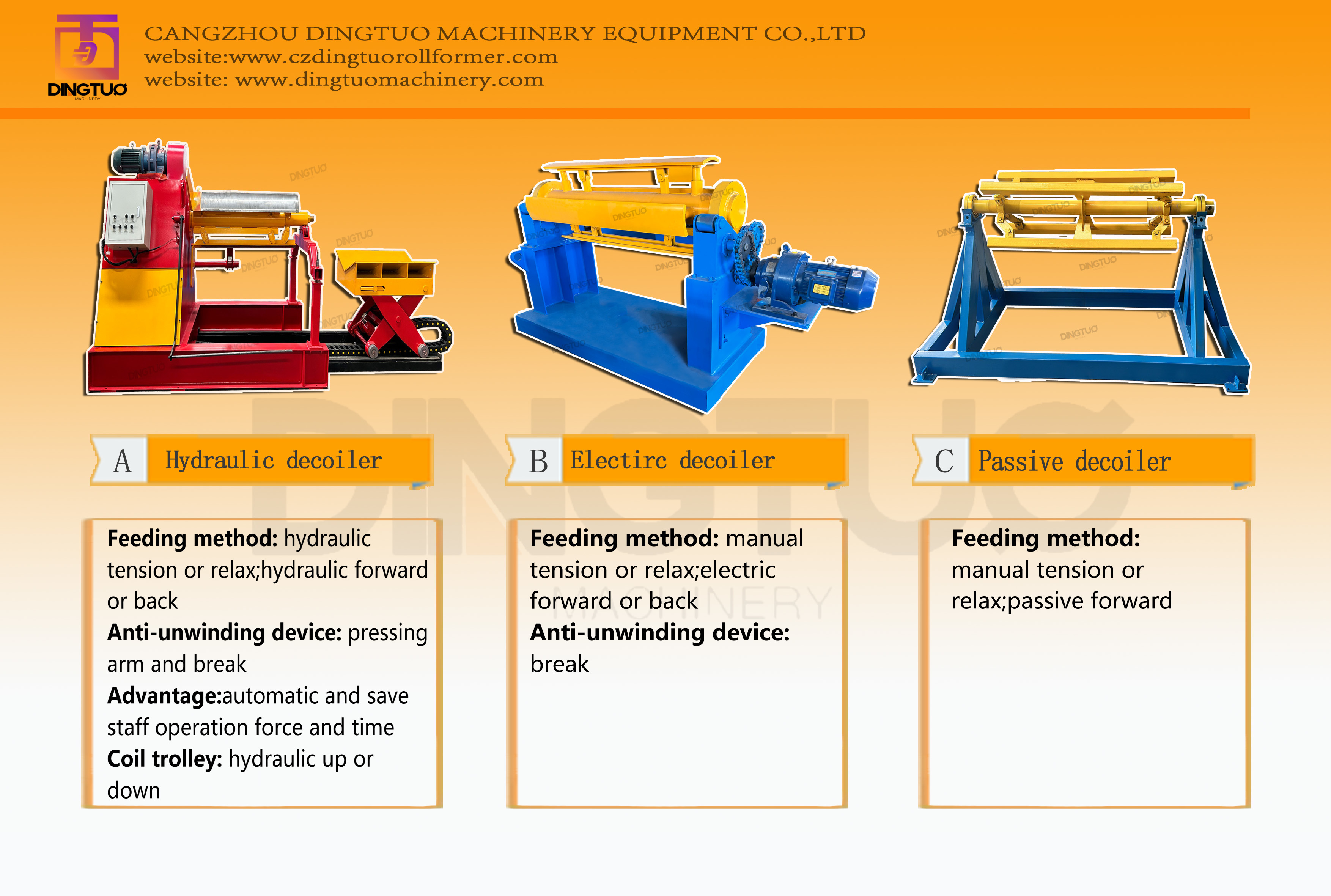

1.Decoiler :save operation time

there had hydraulic decoiler / electric decoiler/ manual standard decoiler can be chose

2.Pre-cutting unit :save materials

There had hydraulic pre-cutter / electric pre-cutter/ manual pre-cutter can be chose

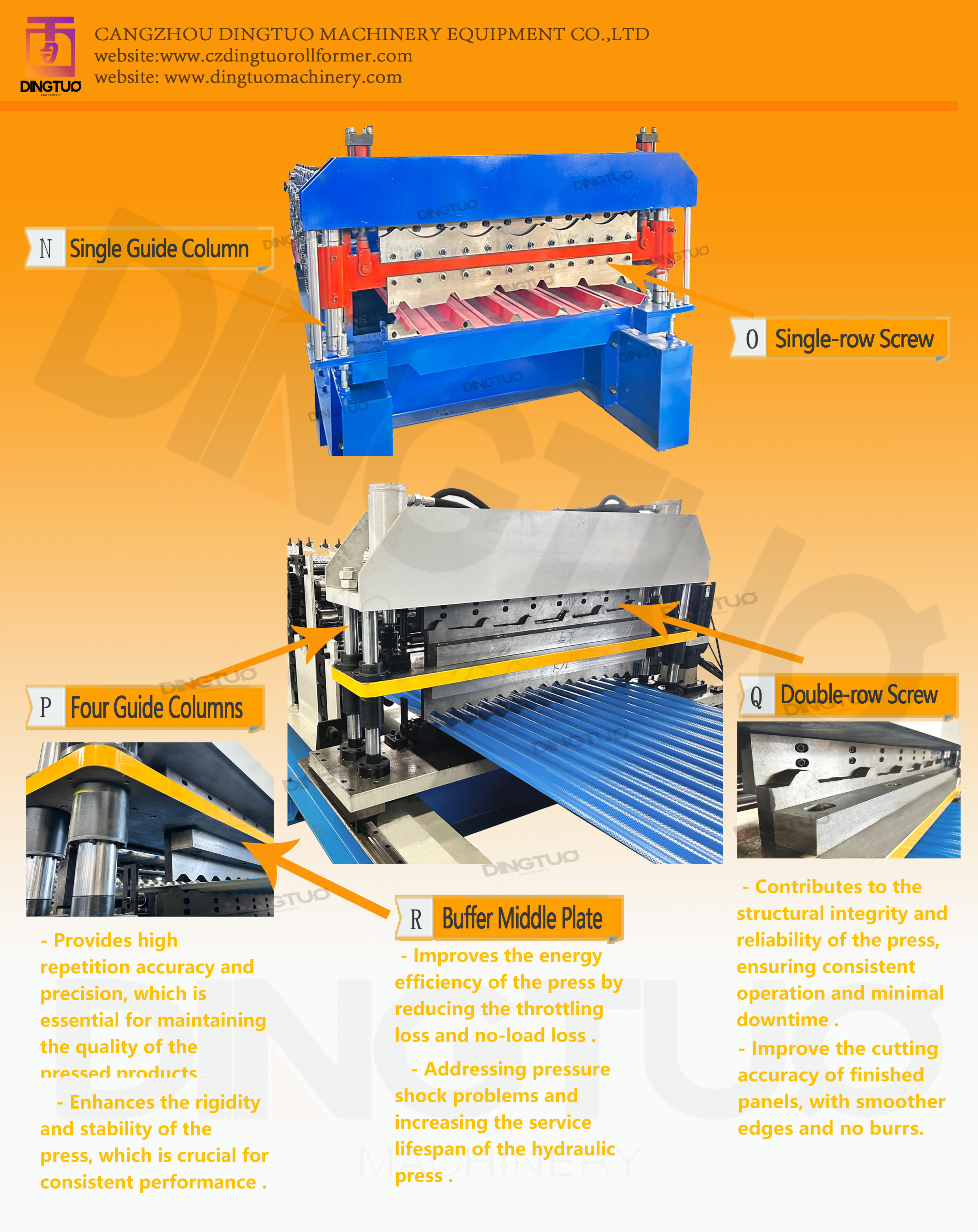

3.Forming unit :structure stable

There had cast iron machine stands /gear boxes transmission type / iron plates welded with chain transmission can be chose

4.Cutting unit :structure stable

There had four pillar guide cutting structure and single pillar guide structure can be chose

5.Run Out Table : save time

There had automatic stacker and standard run out table can be chose

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat