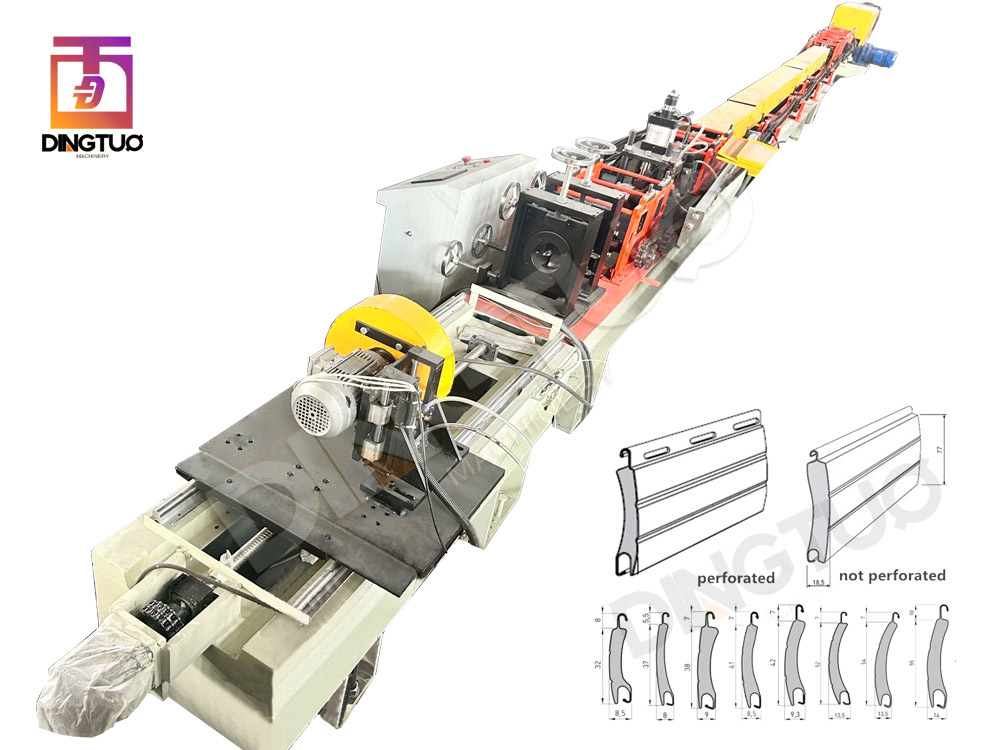

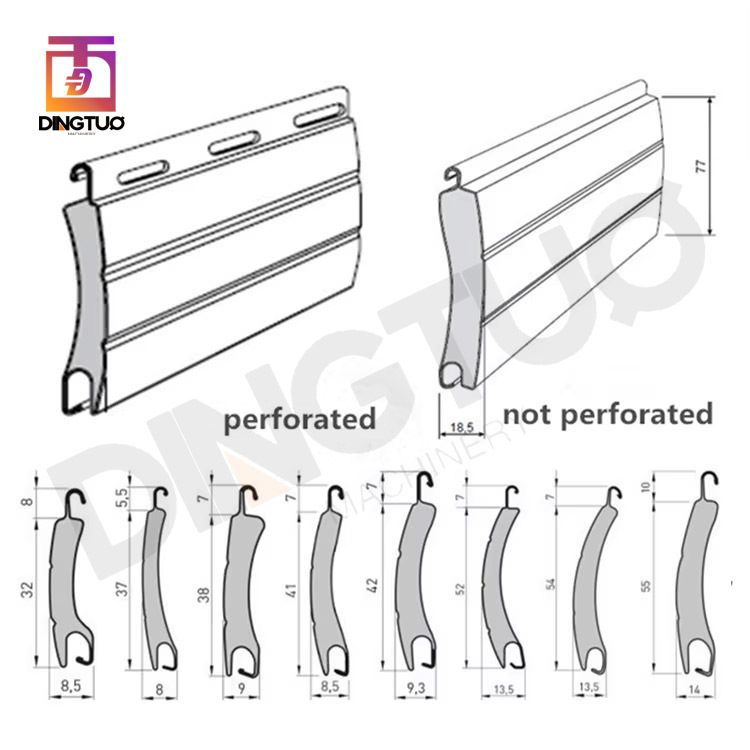

High speed 45 55 77 95 mm PU foam Aluminum roller shutter slats roll forming machine

Key words:

Product category:

Tel/Whatsapp:

High speed 45 55 77 95 mm PU foam Aluminum roller shutter slats roll forming machine

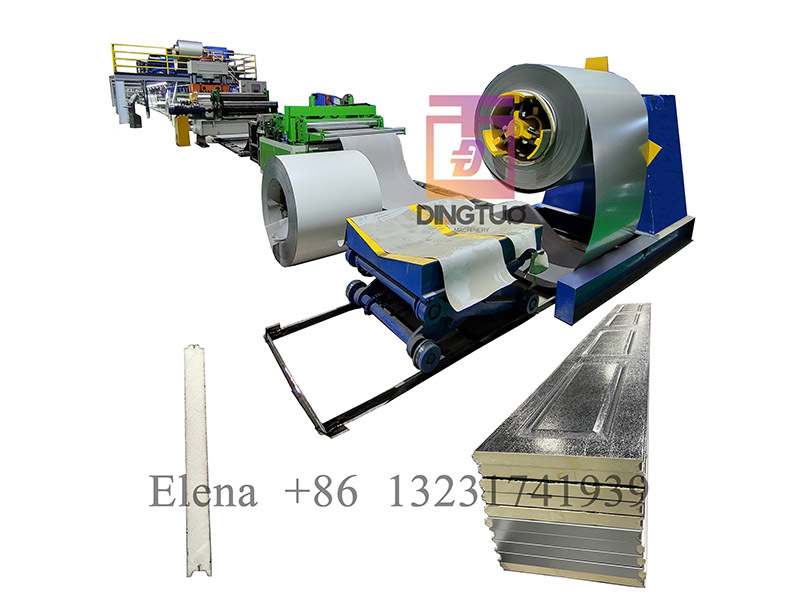

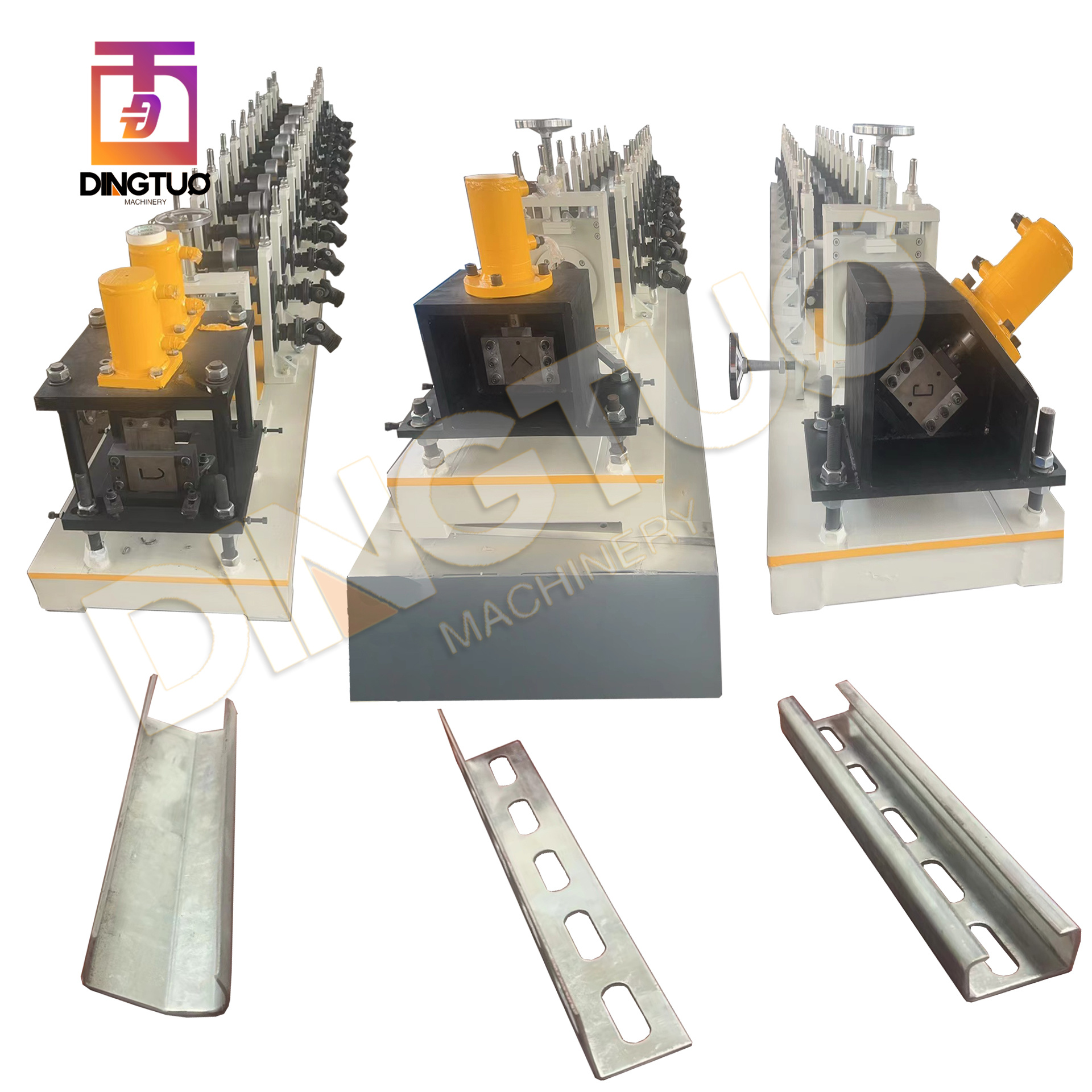

RELATED MACHINES

PU FOAM ROLLER SHUTTER DOOR ROLL FORMING MACHINE

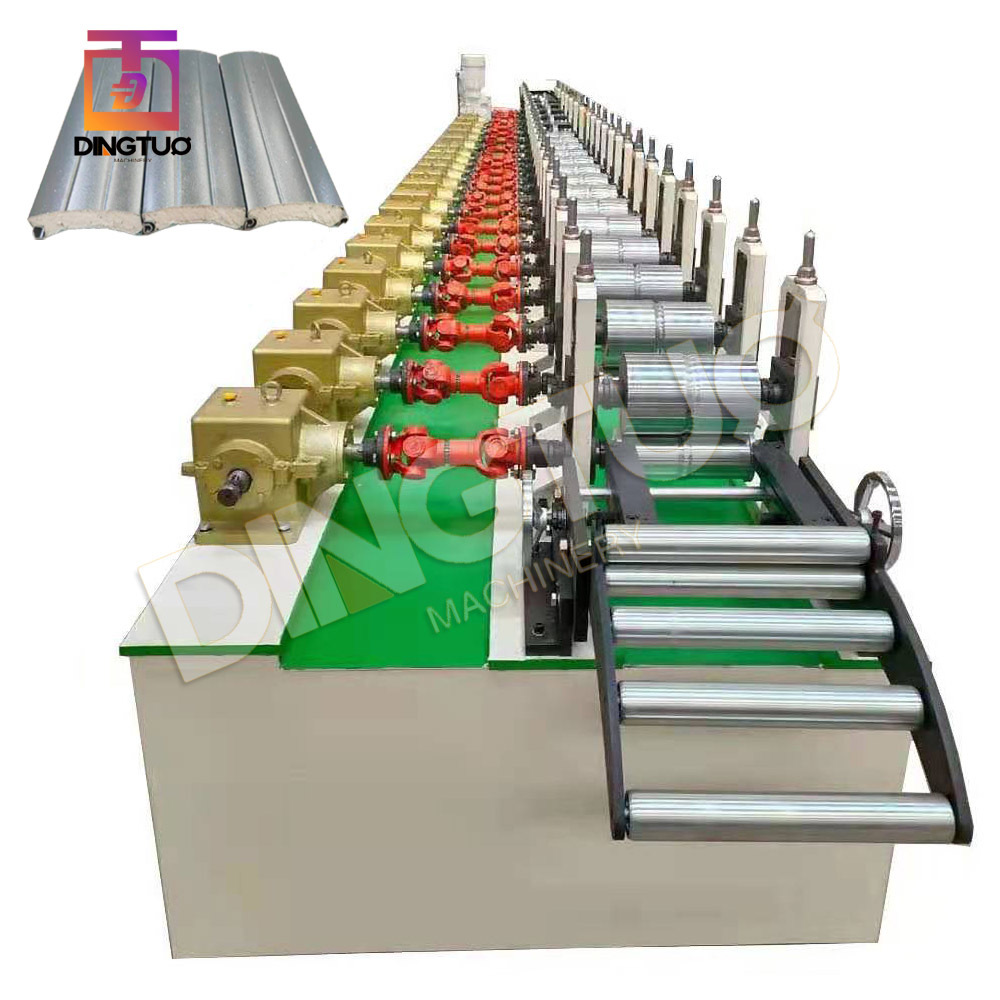

Introducing our PU foam rolling shutter slats roll forming machine, designed with a robust cast iron frame and utilizing gearbox transmission for enhanced stability during operation. This reliable structure ensures that the machine runs smoothly and consistently. Capable of achieving speeds of up to 35 meters per minute, this machine efficiently produces PU foam slats, typically crafted from aluminum sheets ranging from 0.2 to 0.3 mm in thickness. By opting for a high-pressure foaming machine, users can achieve a high-density and uniform foam, resulting in products that boast exceptional anti-theft capabilities, excellent heat preservation, and superior thermal insulation properties. For top-quality and highly reliable PU foam roller shutter door machines, choose Cangzhou Dingtuo Machinery as your trusted supplier.

MACHINE COMPONENTS

NO. | Description | Quantity (set) |

1 | 3T decoiler | 1 |

2 | Feeding Platform | 1 |

3 | Forming System | 1 |

4 | Transmission system | 1 |

5 | injection glue with Air blowing high pressure foaming machine | 1 |

6 | Insulation oven | 1 |

7 | servo hydraulic flying punching unit | 1 |

8 | Hydraulic flying saw cutting system | 1 |

9 | Hydraulic pump station | 1 |

10 | Electric Control Cabinet | 1 |

11 | run out table | 1 |

12 | Spare parts and tools | 1 |

MACHINE PARAMETERS

No | Item | Parameter |

1 | Raw material | aluminum |

2 | Thickness | 0.28-0.35 mm |

3 | Feeding width/coil width | customized |

4 | Useful width | customized |

5 | Machine stands | cast iron |

6 | Forming Speed | 35-40 m/min |

7 | Forming station | 37 |

8 | Total Power | 7.5 kw (main motor power) + 2.2 KW(hydraulic pump station motor power for punching ) |

9 | Mill bed material | whole iron plates welded |

10 | Voltage | 380 V , 50HZ, 3 Phases or customized |

11 | Diameter of shaft | 40mm diameter solid shafts ( fine grinding) |

12 | Cutting type | flying saw cutting type |

13 | Forming Shaft | 45# steel with grinding process |

14 | Forming Roller | 45# steel, CNC machined after overall quenching, hardness can reach HRC55-58°, with the advantages of high strength, high hardness, high precision and long service life |

15 | Cutting Blade | Cr12 with hard treatment |

16 | Transmission | gearboxes |

17 | PLC | DELTA Brands /MITSUBISHI |

18 | Touch Screen | DELTA Brand/MITSUBISHI |

19 | hydraulic punching | servo flying punch |

20 | Encoder | OMRON Brand with aluminum bracket |

21 | Low-voltage electrical | SCHNEIDER Brands |

22 | One air-blowing high pressure foaming machine | High density, uniform foaming. High anti-theft, high heat preservation, high thermal insulation performance |

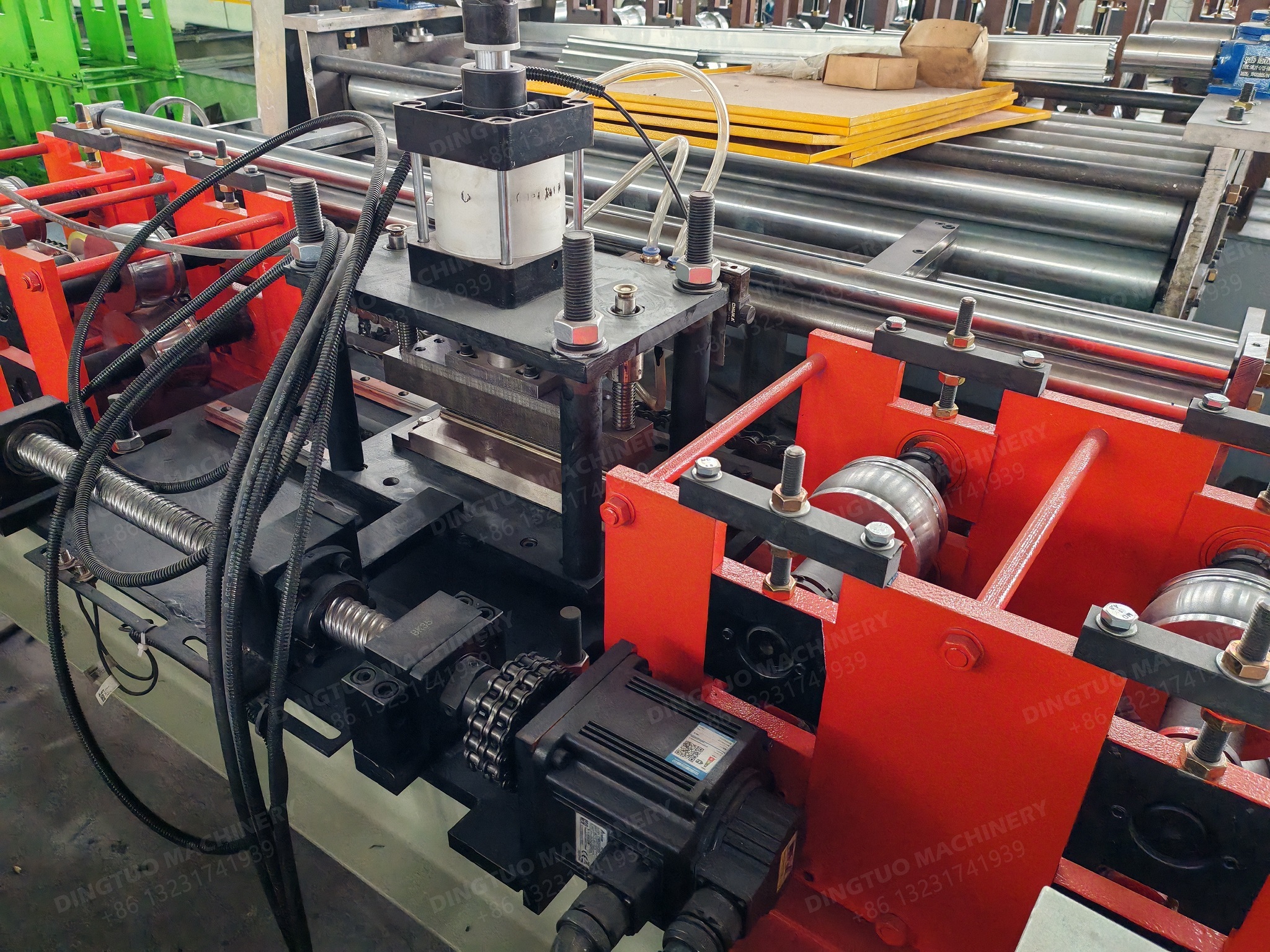

MACHINE DETAILS

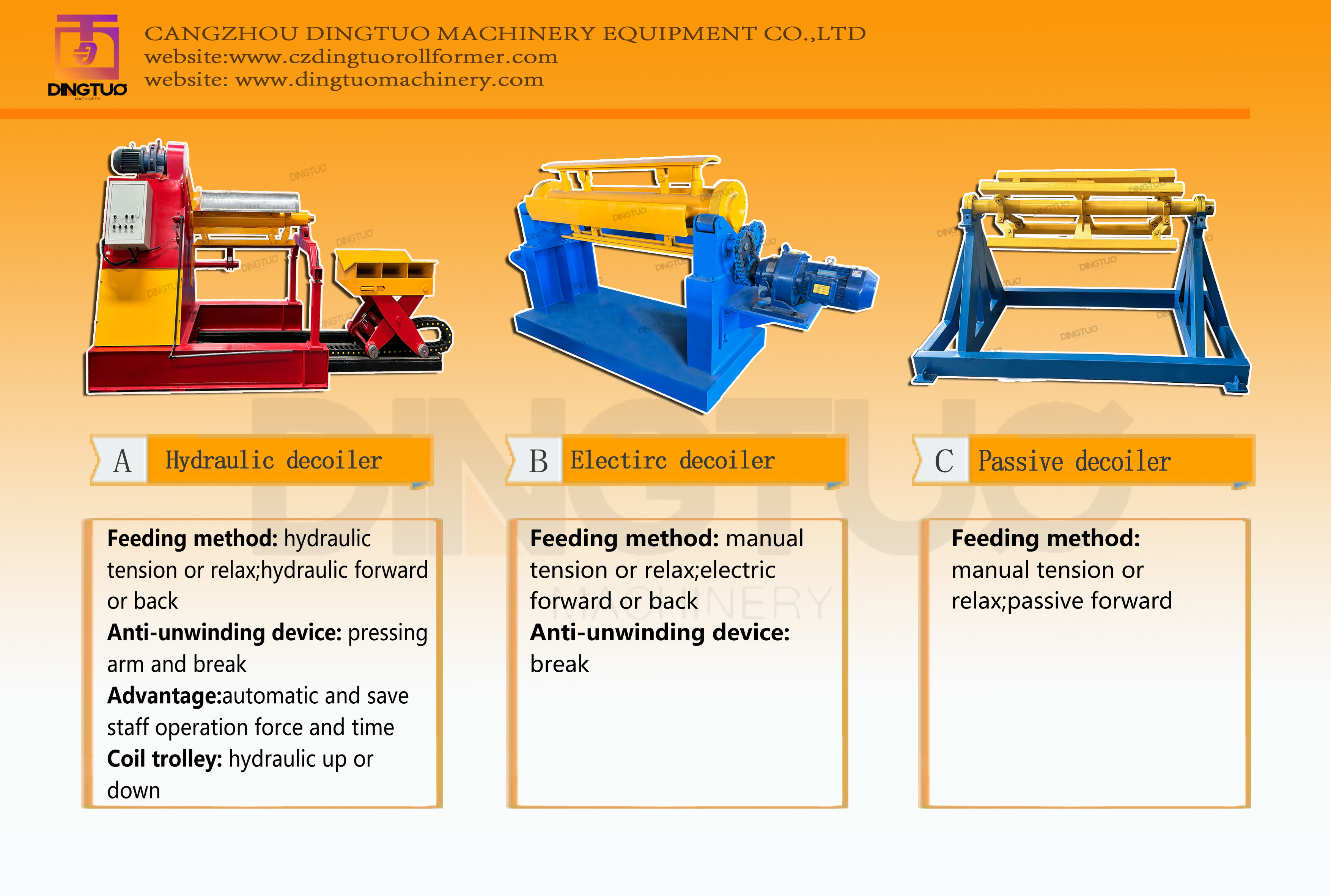

1.DECOILER . THE A B C TYPE YOU CAN CHOOSE . C IS FREE WITH MACHINE

2. FORMING MACHINE . GEARBOXES TRANSMISSION + CAST IRON MACHINE STANDS

3. INJECTION GLUE AND HIGH PRESSURE PU FOAMING MACHINE

4. INSULATION OVEN

Install an insulation box before and after foaming to heat the material and help foaming.

4. ONLINE PERFORATED PUNCHING UNIT ( OPTIONAL) : FLYING PUNCH BY SERVO MOTOR .

After the punched PU foam rolling shutter door is assembled, a faint light will shine in, making the finished product more beautiful.

5. MACHINE FLYING SAW CUTTING UNIT

6. MACHINE RUN OUT TABLE

7. MACHINE ACCESSORIES

No. | Name | Quantity | Country |

1 | Rely | several | China |

2 | Encoder | 1pcs | China |

3 | Encoder wheels | 2pcs | China |

4 | bearings | 2pcs | China |

5 | Travelling Buttons | 2pcs | China |

6 | Switch buttons | 3pcs | China |

7 | The electromagnetic valve | 1pcs | China |

8 | Oil tubes | 2pcs | China |

9 | Gears | 2pcs | China |

10 | Chains | 2meters | China |

11 | circlip | Several | China |

12 | Tool Box | 1 Set | China |

Upgrade your roofing production with our quality metal self lock roofing sheet roll forming machine – engineered to deliver flawless, high-strength roofing sheets with secure interlocking edges. Designed for manufacturers seeking durability, efficiency, and precision, this machine ensures weatherproof, leak-resistant panels perfect for industrial, commercial, and residential applications.

Why Choose Our Machine?

✔ Self-Locking Technology – Produces interlocking roofing sheets that snap tightly together, eliminating gaps and enhancing structural integrity.

✔ Heavy-Duty Performance – Constructed with high-grade steel and hardened rollers for long-lasting operation, even under continuous use.

✔ Customizable Profiles – Adjustable roll-forming system supports multiple sheet designs (trapezoidal, standing seam, etc.) to meet diverse project needs.

✔ High-Speed Production – Automated PLC control enables fast output (15-30m/min) while maintaining consistent thickness and accuracy.

✔ Low Maintenance & Energy Efficient – Optimized design reduces downtime and power consumption, maximizing ROI.

Invest in a quality metal self lock roofing sheet roll forming machine that guarantees smooth operation, minimal waste, and superior corrosion-resistant panels. Trusted by global manufacturers, our machine combines advanced engineering with cost-effective production.

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat