YX 153-840 Roof Decking Floor Roll Forming Machine Used for Russia Norway Bolivia Europe Area

Key words:

Product category:

Tel/Whatsapp:

YX 153-840 Roof Decking Floor Roll Forming Machine Used for Russia Norway Bolivia Europe Area

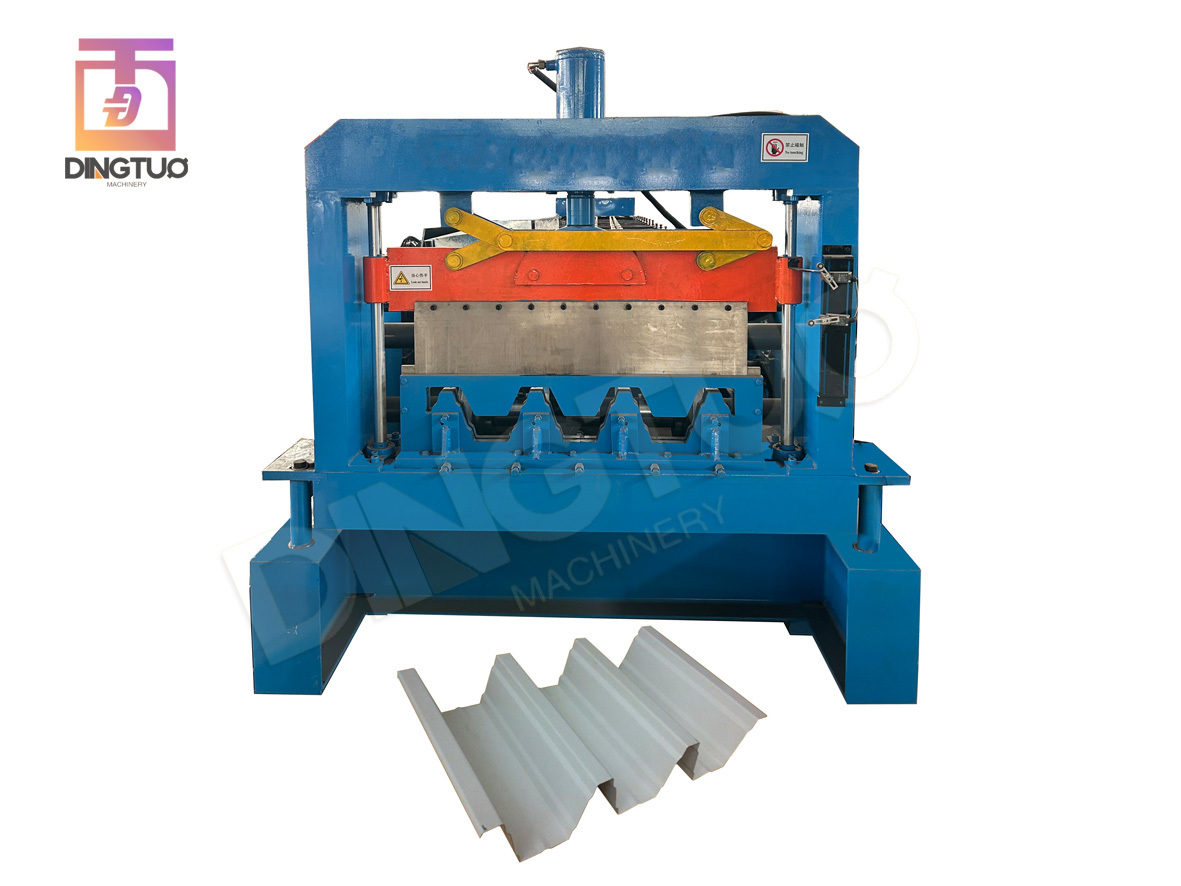

D153-840 Roof Decking Floor Roll Former

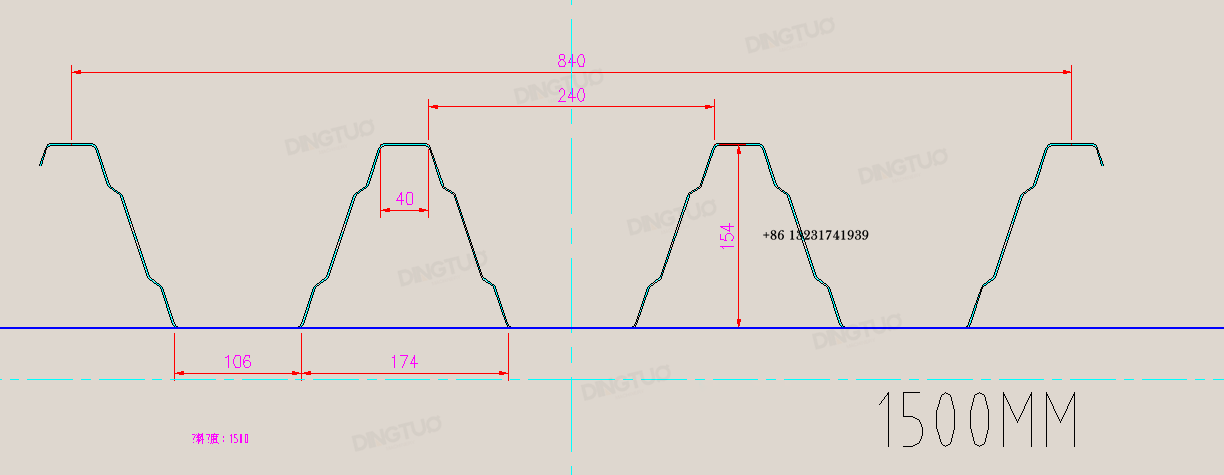

This metal roof deck D153 profile roll forming machine is designed for creating sturdy and reliable roof decking floor panels. The machine has a coil width of 1500mm and an effective width of 840mm, making it ideal for large-scale roofing projects. The thickness of the metal can be customized according to your specific requirements, typically ranging from 0.8mm to 1.5mm. With a weight of 34000 KGS, this machine is built to last and withstand the rigors of continuous use. Its durable construction and precise engineering ensure high-quality results with every use. Whether you are a professional contractor or a DIY enthusiast, this roll forming machine is the perfect choice for producing top-notch metal roof decks.

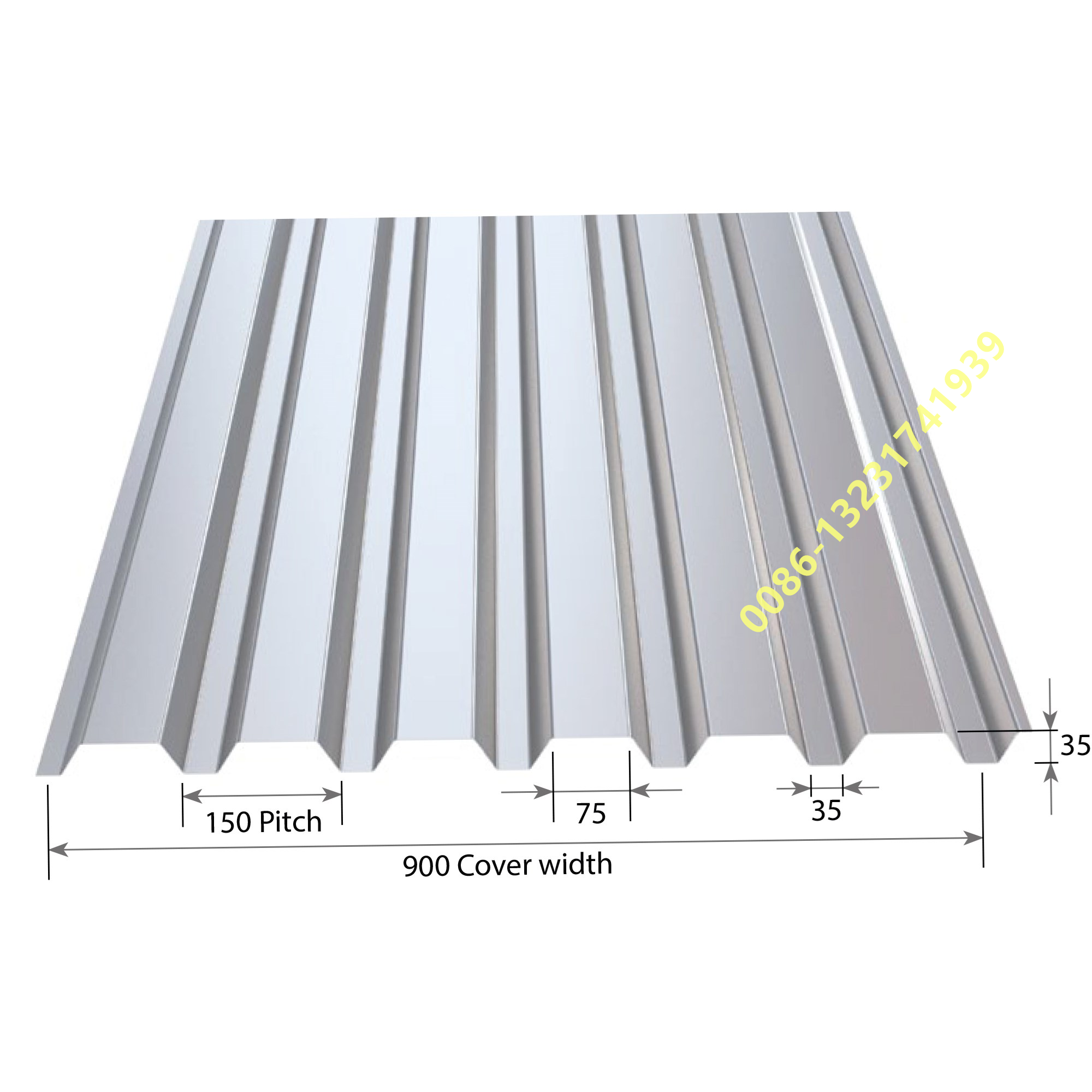

Profile Drawing

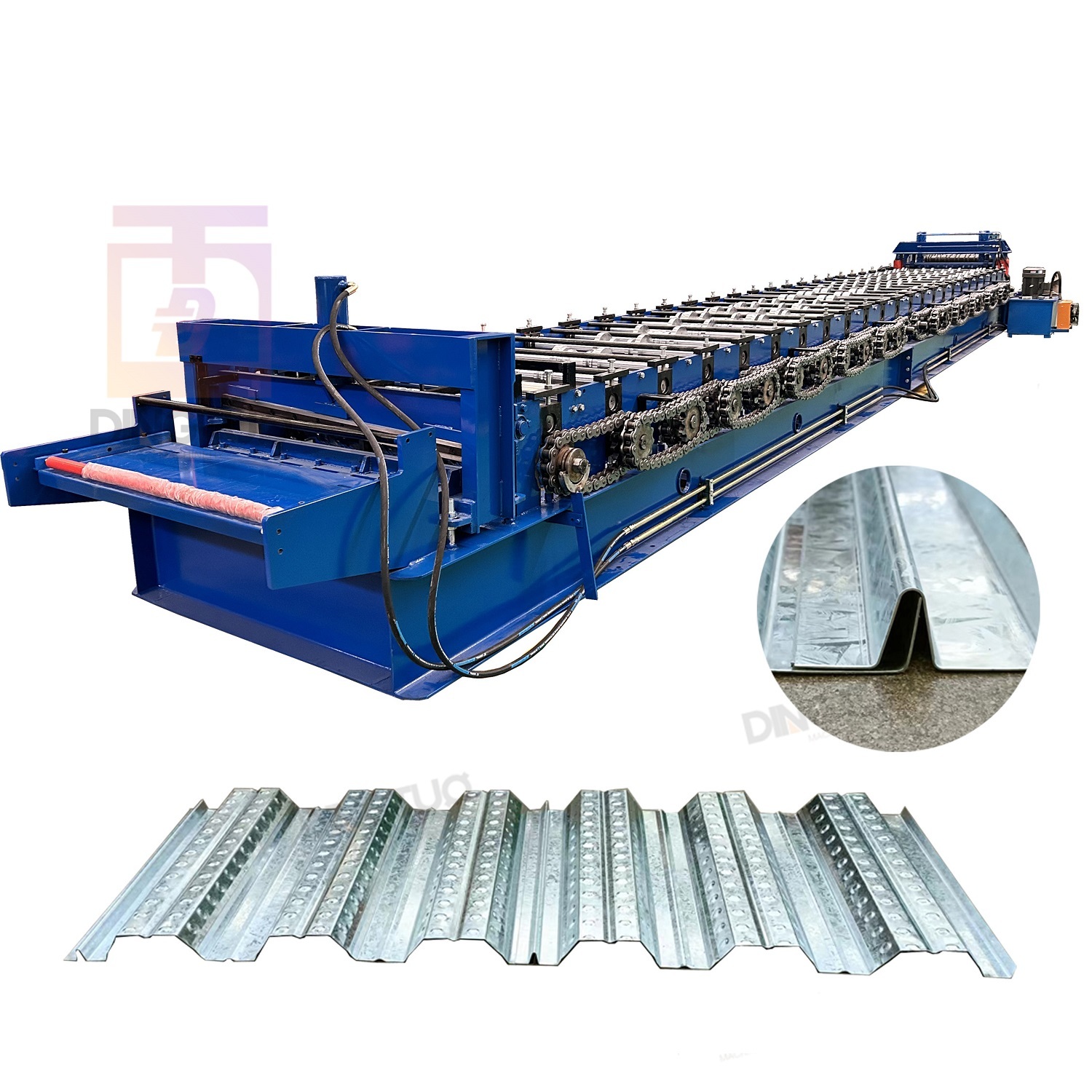

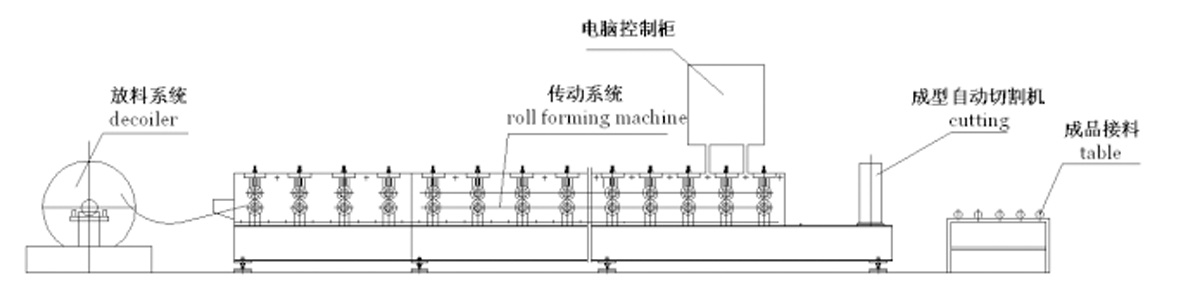

Working Flow

General parameters

| No | Item | Configuration | Configuration Explanation |

| 1 | Raw material | PPGI/GI | Meet your requirements |

| 2 | Thickness | 0.8-1.6 mm | Meet your requirements |

| 3 | Feeding width | 1500 mm | According to your profile drawing |

| 4 | Side wall thickness | 25mm | This machine stands’ have enough thickness to support the machine at high speed |

| 5 | Forming Speed | 30m/min | Your material thickness(max.16 gauge) decided the maximum speed is 30m/min |

| 6 | Forming station | 40 stations included 1 station embossing wheels | Calculated the stations according to your profile drawing. The stations will neither more nor less. |

| 7 | Total Power | 45kw (main motor power)+ 7.5kw hydraulic motors | This configuration can ensure the machine’s speed to 30m/min and can meet your special voltage. |

| 8 | Mill bed material | 450H beam which nation standard thickness is 10 mm | High-end exported standard |

| 9 | Voltage | 240V,60HZ,3 phases | According to your request |

| 10 | Diameter of shaft | 100 mm solid shafts | Your needed material thickness and high speed decided to use |

| 11 | Cutting Type | Automatic hydraulic cutting | Standard |

| 12 | Knife holder | Super thick | The shock absorption effect is obvious, and the impact resistance is strong |

| 13 | Forming Shaft | 45# steel with grinding process | Exported standard |

| 14 | Forming Roller | Bearing steel GCr15 roller material | The rollers must use Gcr15 bearing steel material which has more finish and can guarantee your profile perfect |

| 15 | Cutting Blade | Cr12 with hard treatment and three-piece knife cutting | Shear life more than 1 million times |

| 16 | Chain and sprocket | 2 inches chains | Because high speed, so, the chains and sprockets we give your machine used the best brand . High-end exported standard |

| 17 | Bearing Type | 213 type HRB Bearing brand | Because high speed , so, the bearings must use bigger size than ordinary speed machine. High-end exported standard |

| 18 | PLC/Touch Screen | DELTA Brand | From TAIWAN,CHINA |

| 19 | Electrical motor | SHANGHAI LICHAO brand | Top quality |

| 20 | Encoder | OMRON Brand | From JAPAN |

| 21 | Low-Voltage Electrics | SCHNEIDER Brand | From FRANCE |

| 22 | Machine Size | L 26m | need 2*40ft container |

| 23 | Machine weight | 34 tons | heavy-duty type |

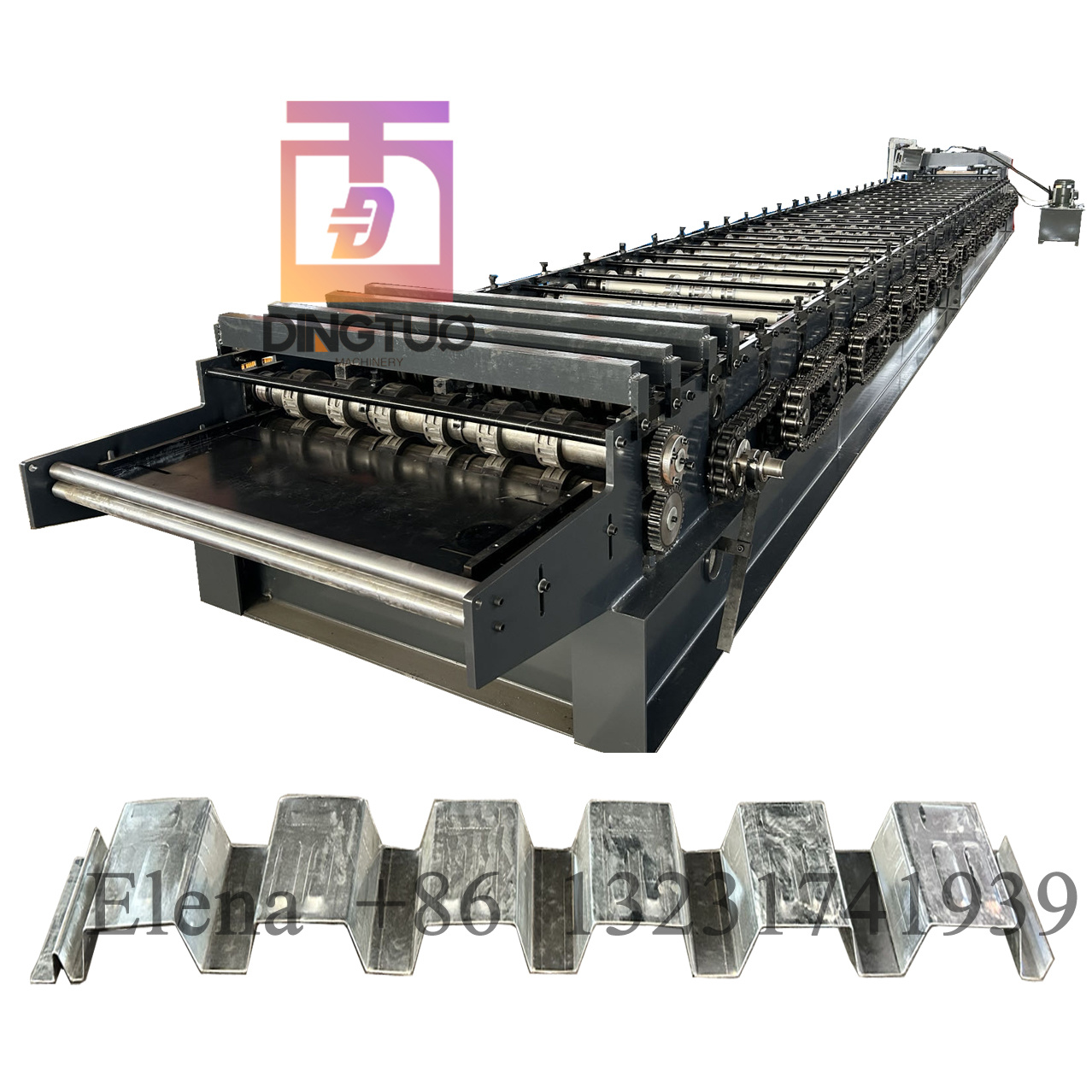

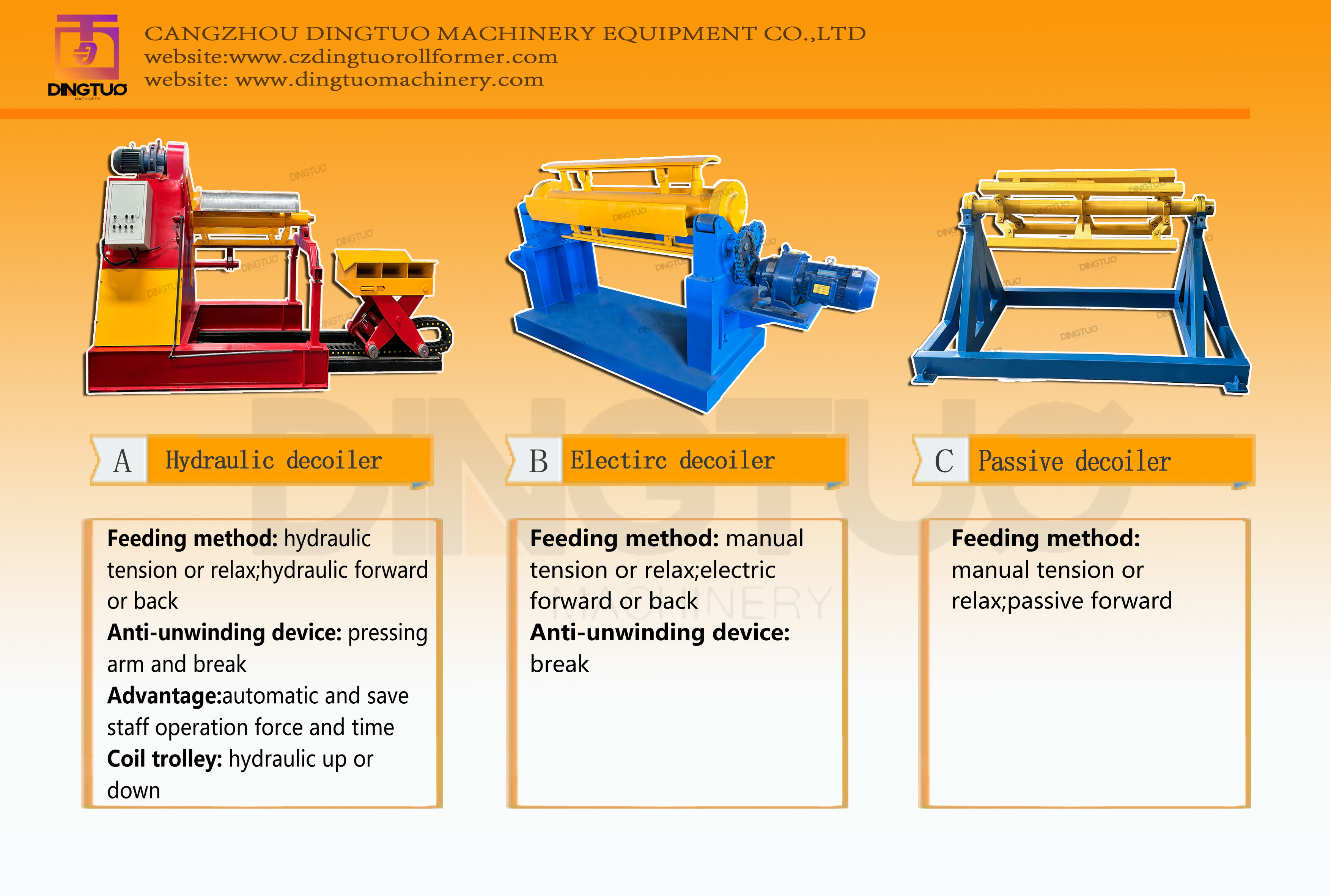

1. Decoiler : there had hydraulic decoiler/ electric decoiler / manual decoiler can be choose

2. Pre-Cutter : there had hydraulic pre-cutter / no need pre-cutter can be choose

3. Forming Unit :40 forming station ( height too high 153mm ) There also had cast iron machine stands with gear boxes transmission machine configuration can be choose

4. Automatic Hydraulic Cut

5. Run Out Table: There had automatic stacker and Manual run out table can be choose

Spare Part

No. | Name | Quantity | Country |

1 | Rely | 2pcs | China |

2 | Encoder | 2pcs | China |

3 | Encoder wheels | 2pcs | China |

4 | bearings | 2pcs | China |

5 | limit switch | 2pcs | China |

6 | Switch buttons | 3pcs | China |

7 | sensor | 4pcs | China |

8 | Oil tubes | 2pcs | China |

9 | Gears | 2pcs | China |

11 | circlip | 30pcs | China |

12 | Tool Box | 1 Set | China |

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat