METAL 6''ROUND DOWNSPOUT ROLL FORMING MACHINE WITH ELECTRIC CUT

Key words:

Product category:

Tel/Whatsapp:

METAL 6''ROUND DOWNSPOUT ROLL FORMING MACHINE WITH ELECTRIC CUT

METAL 3''/4''/6''ROUND DOWNSPOUT ROLL FORMER

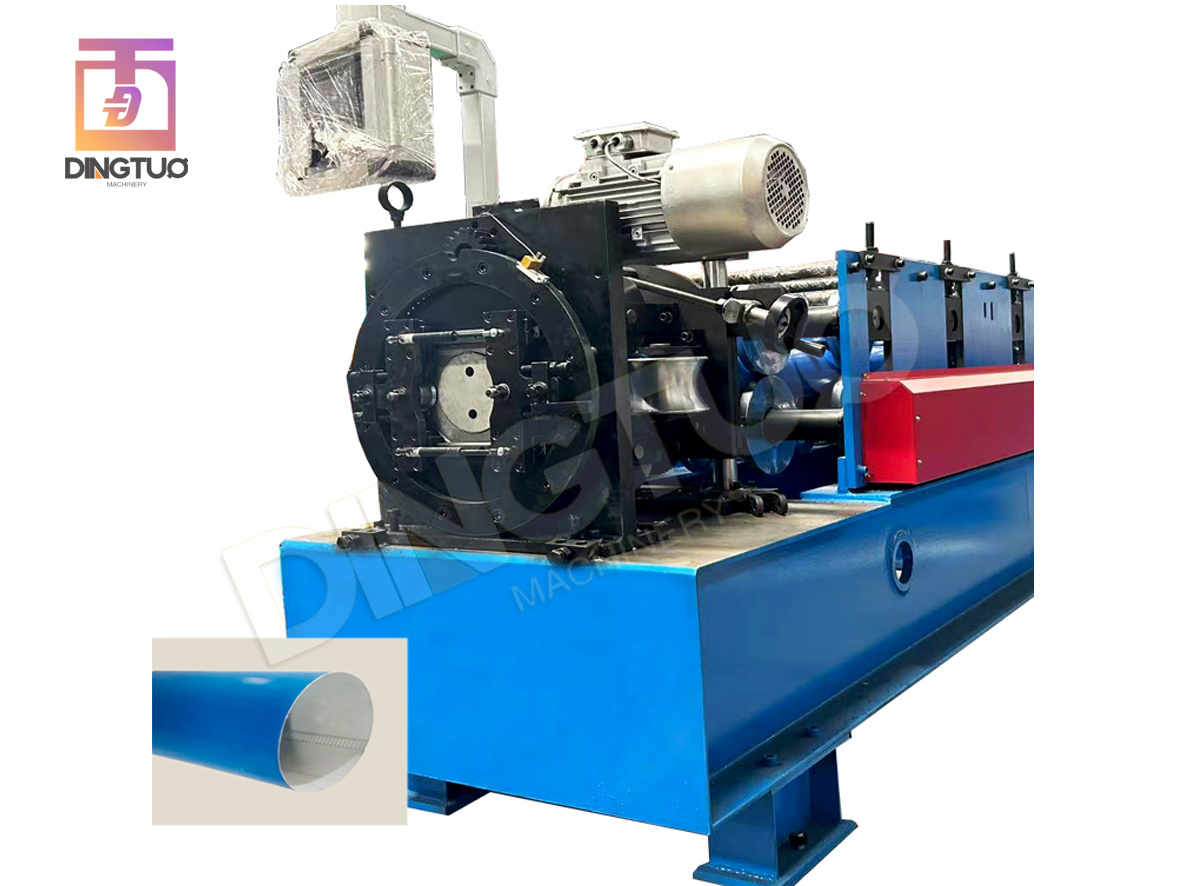

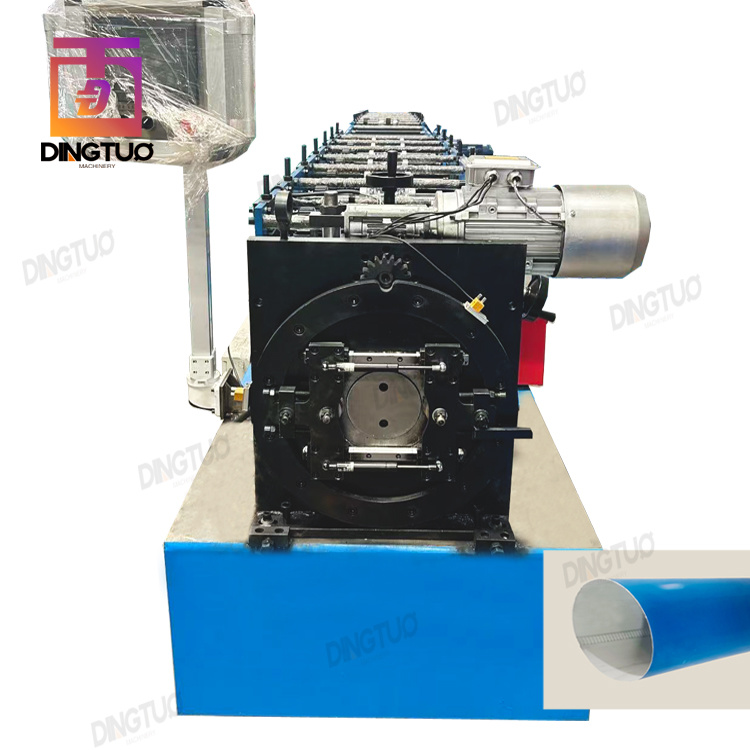

The downpipe machine adopts PLC automatic control mode, which can automatically cut to length, bend at fixed arc, and shrink manually according to the input length, quantity, arc size and other parameters.

The metal downspout roll forming machine is composed of decoiler, feeding platform, roll forming unit, cutting unit, elbow unit, necking unit, finished product run out table, electric control system, hydraulic system and so on.

The whole set of downspout machine adopts Delta inverter, PLC and touch screen, and Omron encoder counts, which can be controlled manually and automatically. About the downspout sizes, usually 3''X4'' , 2''X3'' rectangular downspouts , 5 inch square downspout, 80mm/89mm/100mm/108mm/150mm...round downspouts sizes can be customized.........And you can choose only straight downspout forming machine , and can also choose elbow function and necking function in one machine or separated machine as your needed.

Machine Schematic

NO. | Description | Quantity (set) |

1 | 1.5 T manual decoiler | 1 |

2 | Feeding Platform | 1 |

3 | Forming system | 1 |

4 | Transmission system | 1 |

5 | Automatic Hydraulic Cut | 1 |

6 | Run-out table | 1 |

7 | Hydraulic pump station | 1 |

8 | Electric Control Cabinet | 1 |

9 | Spare parts and tools | 1 |

Metal Rectangular Downspout Forming Machine Parameter

No | Item | Parameter |

1 | Raw Material | Aluminum/PPGI / Copper, Q235 , 0.5-0.8mm |

1 | Decoiler | 1. Feeding method: passive feeding 2. Rolling method: manual tightening 3. Suitable coil inner diameter: φ508mm 4. Suitable coil outer diameter:<φ1400mm 5. Load: 1.5 tons |

2 | Profile Size | 80mm 3 inch or customzied |

3 | Side stands’ thickness | 16mm |

4 | Forming Speed | 5 m/min |

5 | Forming station | 21 stations |

6 | Total Power | 7.5 kw (Kserious main motor power) + 5.5 KW(hydraulic pump station motor power) |

7 | Mill bed material | 150*150 square tubes welded or H beam welded |

8 | Voltage | 380 V 50HZ 3 phases |

9 | Diameter of shaft | 70mm diameter solid shafts |

10 | Cutting type | Automatic Oblique shear |

11 | Forming Shaft | Material : 45# steel. Processing technology: quenching and tempering treatment HB210-230 + lathe rough turning + CNC lathe fine turning shape + milling machine processing keyway and round nut stop groove. |

12 | Forming Roller | Material: 45# steel, processing technology: fine turning + wire cutting keyway + surface polishing and hard chrome plating. |

13 | Cutting Blade | Material : Cr12 processing technology: rough material milling machine processing - vacuum heat treatment HRC58-60 - flat grinding processing end face - wire cutting processing outline - engraving machine fine carving shape. |

14 | Chain size | One inch |

15 | Run Out Table Function | The frame is welded by profiled materials. The top of the frame is equipped with several rollers, and the bottom is composed of adjusting screws, which can match the height of the finished product within a certain range. |

16 | Run Out table Length | 2m *2 sets |

17 | PLC Brand | DELTA Brand |

18 | Touch Screen Brand(HMI) | DELTA Brand |

19 | Frequency Brand | DELTA Brand |

20 | Electrical motor | Top brand , quality tested, stable Performance. |

21 | Encoder | OMRON Brand with aluminum bracket |

22 | Low-voltage electrical | Top brand , quality tested, stable Performance. |

23 | Machine rough size | L 11m * W 0.8m * 1.2m |

24 | Machine rough weight | 7000 KGS |

25 | Machine with anchor bolts | can level the machine on the ground |

Spare Part

No. | Name | Quantity | Country |

1 | Rely | several | China |

2 | Encoder | 1pcs | China |

3 | Encoder wheels | 2pcs | China |

4 | bearings | 2pcs | China |

5 | Travelling Buttons | 2pcs | China |

6 | Switch buttons | 3pcs | China |

7 | The electromagnetic valve | 1pcs | China |

8 | Oil tubes | 2pcs | China |

9 | Gears | 2pcs | China |

10 | Chains | 2meters | China |

11 | circlip | Several | China |

12 | Tool Box | 1 Set | China |

1.Decoiler :save operation time

there had hydraulic decoiler / electric decoiler/ manual standard decoiler can be chose

2.Pre-cutting unit :save materials

There had hydraulic pre-cutter / electric pre-cutter/ manual pre-cutter can be chose

3.Forming unit :structure stable

The machine stands we use CNC milling and screw connection which have more complex machining process.Clients can receive more higher precision machine and make more higher procesion ridge caps.

4.Cutting unit :Eelctric cutting type without scraps and without any deformation and can cut up to 0.8 mm thick material

5.Run Out Table : stable

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat