2 waves W Beam Crash Barrier Machine for guardrails

Key words:

Product category:

Tel/Whatsapp:

2 waves W Beam Crash Barrier Machine for guardrails

Metal Guardrail Forming Machine With Cast Iron Machine Stands And Gear Boxes Transmission

Product introduction

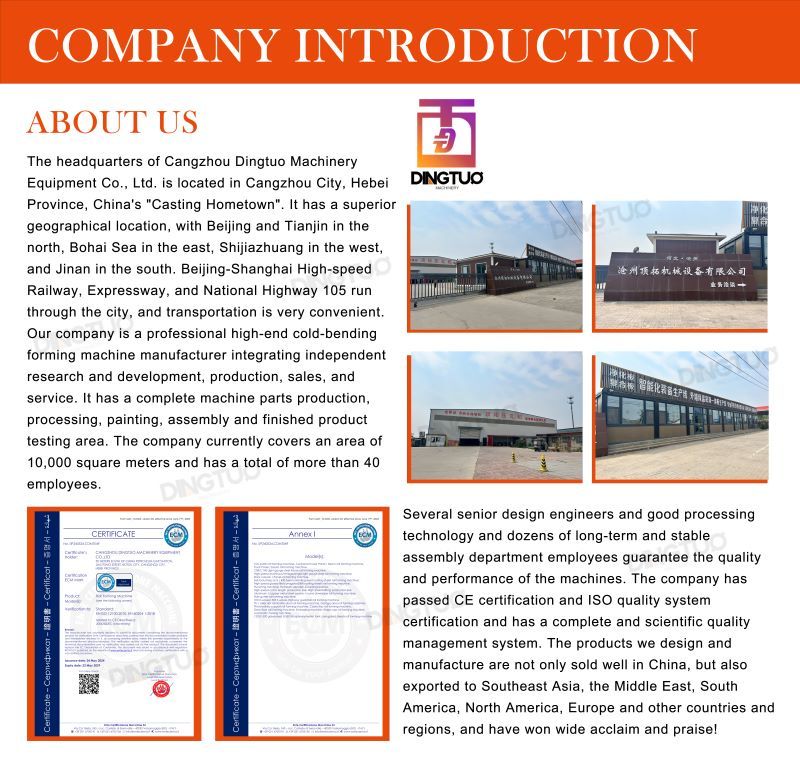

1. The high-speed corrugated guardrail is the main form of the semi-rigid guardrail. It is a continuous structure that is spliced with corrugated steel guardrails and supported by columns.

2. It uses the deformation of the soil foundation, columns, and beams to absorb the collision energy, and forces the out-of-control vehicle to change direction and return to the normal driving direction to prevent the vehicle from rushing out of the road, so as to protect the vehicle and passengers and reduce the loss caused by the accident.

3. The corrugated beam guardrail is soft and soft, has a strong ability to absorb collision energy, has a good line of sight induction function, can be coordinated with the road alignment, and has a beautiful appearance. It can be used on small radius curves, and the damaged part is easy to replace. .

High-speed guardrail equipment generally uses standard specifications and strictly follows the standard requirements.

Highway guardrails and supporting facilities mainly include:

Guardrails, columns, column caps, anti-blocking blocks/brackets, connecting bolts, splicing bolts, beam spacers, ends.

Parameters of high-speed guardrail forming equipment:

· Material thickness: 2.7~4mm

· Forming passes: 15-18 forming passes

· Molding speed: 8-18 m/min

Drive mode: motor drive, gear chain drive, gearbox drive optional

Motor power: optional according to the thickness of the plate, frequency conversion speed regulation

· Cutter material: made of Cr12Mov heat treatment

· Machine base specifications: optional H steel 450, integral square box base, 150*150 square tube base

★ Feeding platform and leveling part:

Based on the right feeding platform, different feeding widths can be adjusted by adjusting the screws and nuts .

★ Forming rollers:

15 stations

roller material : Gcr15 # steel finishing and the surface is plated with hard chrome and polished

105mm solid shafts

sahft maerial : 45# steel processed

★ Electric control cabinet:

stand type

Delta brans or XIEJIE brand

or customzied brands

★ Motor : 2*15kw motors will provide enough power to the 4.5mm material

★ Cut : strong enough knife holder to ensure the cutting stability and ensure the finihsed products effects

Profile Drawing

Machine parts

Machine Parameters (Please Purchase High Grade Raw Materials)

| NO. | DESCRIPTION | PARAMETERS | NOTE |

| 1 | RAW MATERIAL | Q235 STEEL MATERIAL | MEET YOUR REQUEST |

| 2 | THICKNESS | 2MM-3MM | MEET YOUR REQUEST |

| 3 | COIL WIDTH | ACCORDING TO YOUR DRAWING | ACCORDING TO YOUR DRAWING |

| 4 | MACHINE STANDS | 20MM | EXPORTED STANDARD |

| 6 | FORMING STATION | 15 STATIONS | TEH MOST SUITABLE STATIONS CALCULATED BY OUR PROFESSION ENGINEER |

| 7 | MACHINE BASE FRAME | 400H BASE FRAME | H BEAMS WELDED |

| 8 | MACHINE POWER | 2*11 kw (MAIN POWER) +15KW(PUNCH STATION CUTTER+PUCH POWER) | TOTAL 37KW POWER. PUMP STATION WITH COOLING SYSTEM |

| 9 | VOLTAGE | 380 V , 50HZ, 3PHASES | MEET YOUR REQUEST |

| 10 | SHAFT DIAMETER | 90MM SOLID SHAFTS | IT IS ACCORDING TO YOUR THICKNESS AND PROFILE SIZES. 2-3MM THICK MATERIAL, 90MM SOLID SHAFTS ARE ENOUGH. |

| 11 | SHAFT MATERIAL | 45# STEEL | FINE FINISHED |

| 12 | ROLLER MATERIAL | GCR15 BEARING STEEL WITH FINE GRINDING AND HEAT TREATMENT | FINE FINISHED |

| 13 | PLC BRAND | DELTA | FROM TAIWAI , STABLE QUALITY |

| 14 | TOUCH SCREEN BRAND | DELTA | FROM TAIWAI , STABLE QUALITY |

| 15 | MOTOR BRAND | SHANGHAI LICHAO | HIGH QUALITY , STABLE QUALITY |

| 16 | LOW ELECTRIC BRANDS | SCHNEIDER | HIGH QUALITY, STABLE QUALITY |

| 17 | CHAIN TRANSMISSION | Gearboxes | EXPORTED HIGHER STANDARD |

| 18 | CUTTER TYPE | AUTOMATIC HYDRAULIC CUT | ACCORDING TO PROFILE DRAWING |

| 19 | CUTTER MATERIAL | Cr12, FINE TURNING,FINE GRINDING,HRC 58-62°(HEAT TREATMENT) | EXPORTED STANDARD WHICH CUTTER LIFE TIME EXCEEDS 100 MILLION TIMES. |

| 20 | ENCODER BRAND | OMRON BRAND WITH ALUMINUM BRACKET | QUALITY STABILITY |

| 21 | MACHINE SIZE | L11M*W2M*H1.5M | WHEN MACHINE FINISHED, WILL HAVE ACCURATE MACHINE SIZE |

| 22 | MACHINE WEIGHT | 10TONS | WHEN MACHINE FINISHED, WILL HAVE ACCURATE MACHINE WEIGHT |

Machine Etailed Components

7tons Manual Reel Holder (Decoiler)

Feeding Platform And Online Punch Unit

Machine Forming Unit

Machine Automatic Stacker

Machine Bending Unit

Spare Part

|

No. |

Name |

Quantity |

Country |

|

1 |

Encoder |

1pcs |

China |

|

2 |

Encoder wheels |

2pcs |

China |

|

3 |

bearings |

2pcs |

China |

|

4 |

sensors |

2pcs |

China |

|

5 |

Oil tubes |

2pcs |

China |

|

6 |

nuts |

5pcs |

China |

|

7 |

Tool Box |

1 Set |

China |

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat