50 75 100 automatic size adjustable metal stud and track roll forming machine

Key words:

Product category:

Tel/Whatsapp:

50 75 100 automatic size adjustable metal stud and track roll forming machine

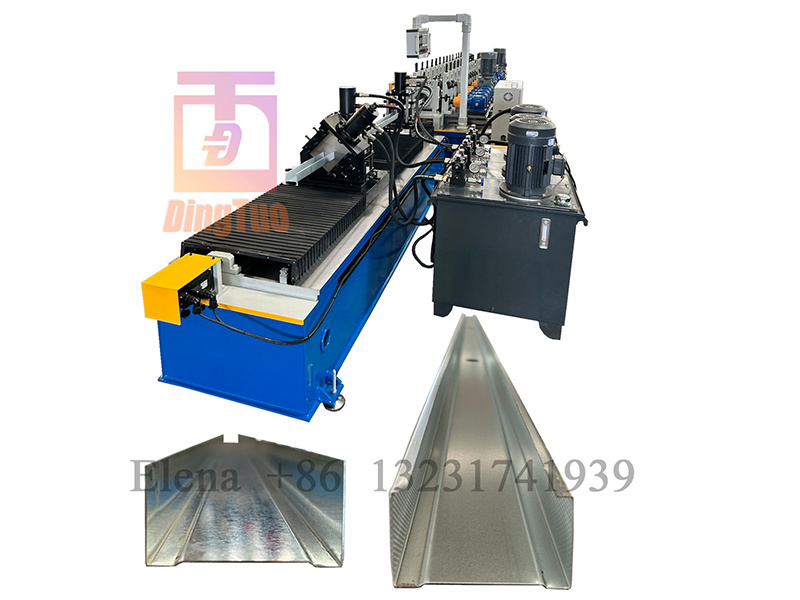

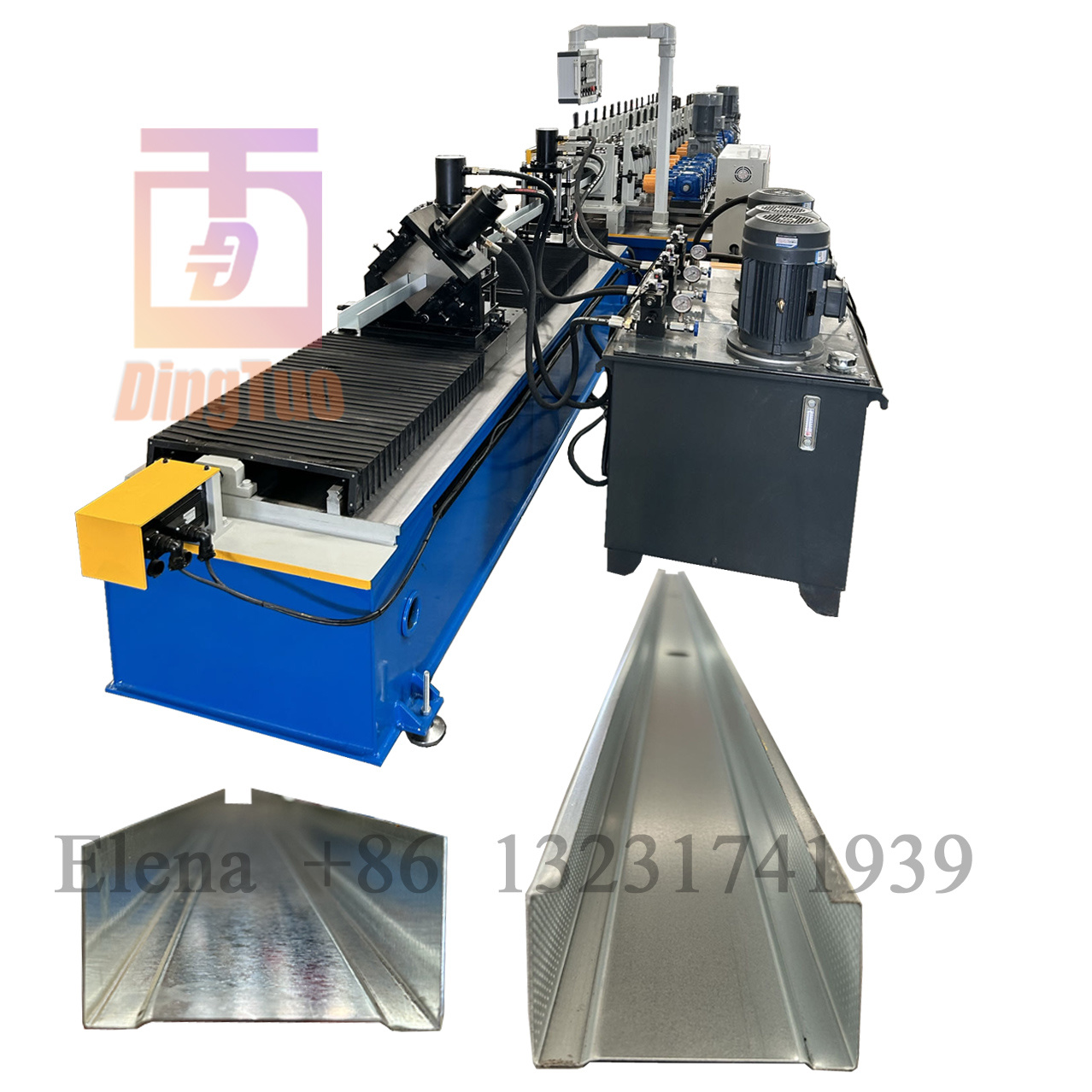

Automatic Size Adjustabel Drywall stud And Track 50-75-100 CU Channel Light Gauge Steel Roll Forming Machine

Machine introduction

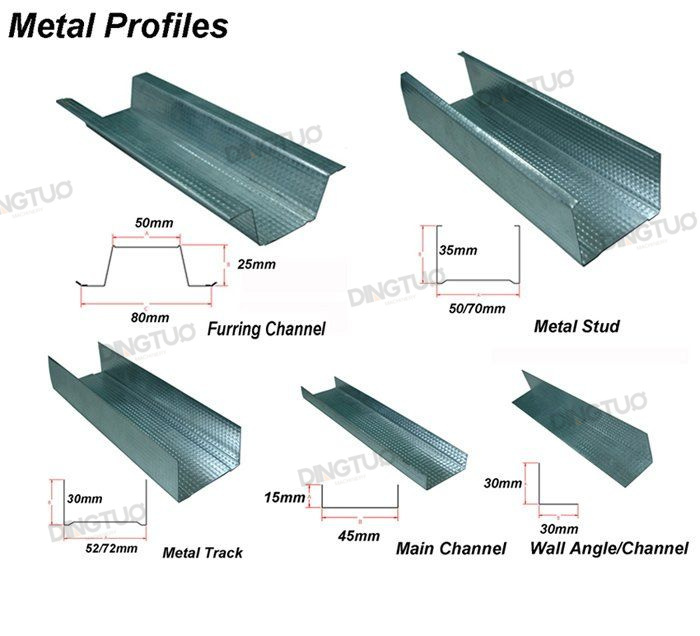

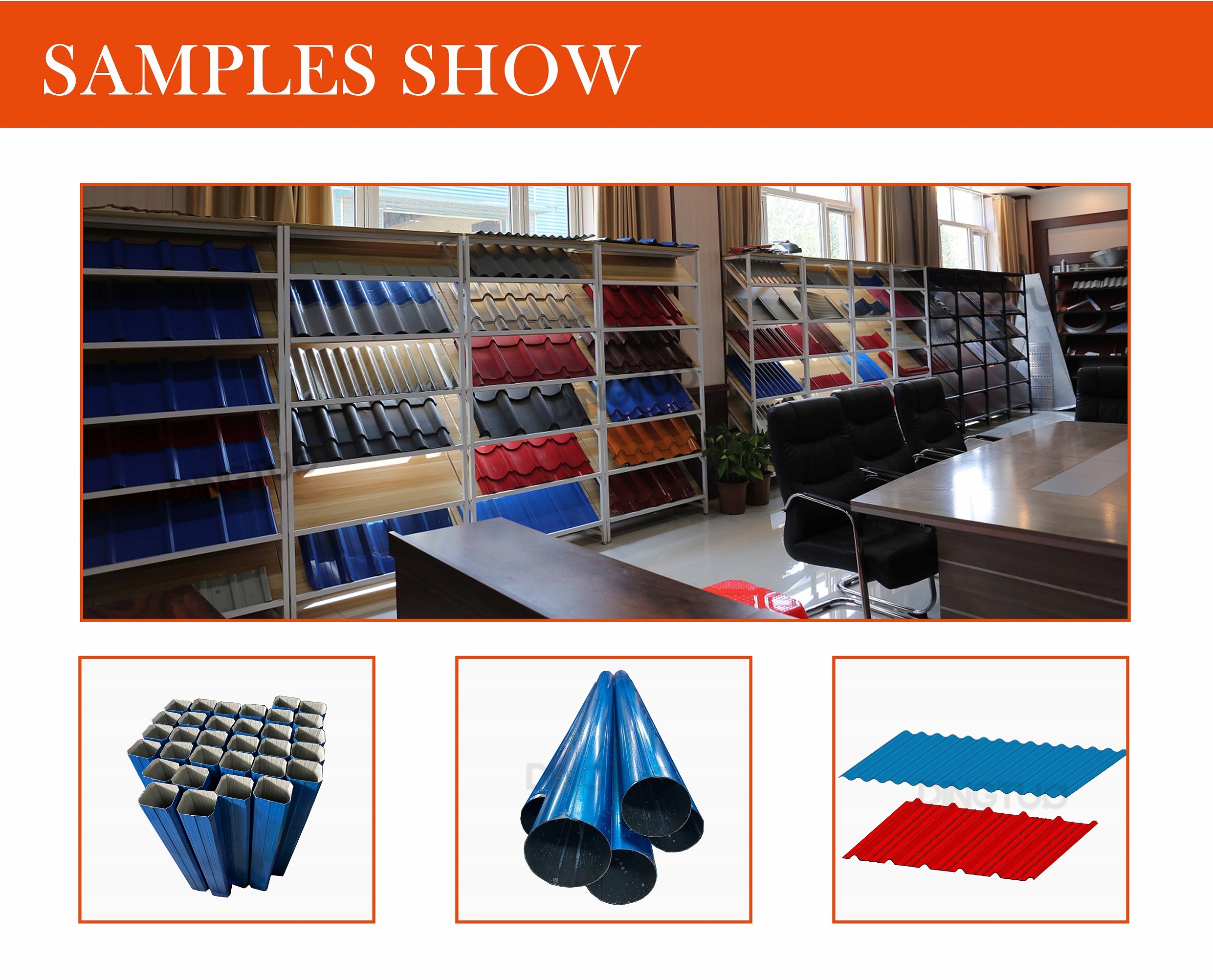

Lightweight steel keel partition walls are characterized by light weight, high strength, good fire resistance, strong versatility and easy installation. They are suitable for shockproof, dustproof, soundproof, sound-absorbing and constant temperature. They also have the advantages of short construction period, simple construction and not easy to deform. Lightweight steel keel is a new type of building material. With the development of modernization, it has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, old building renovation, interior decoration, ceilings and other places in recent years.

The light gauge steel frame machine can do stud and track from 50-100 mm. It can do popular sizes 50 75 and 100 CU channels. The machine used gearboxes transmission and cast iron machine stands . About the punching unit , for improving the machine whole speed and we installed 2 sets of punching unit with cutting unit to do flying punching and flying cut which can keep the machine speed maximum 50 m/min including punching and cutting which greatly improves the production efficiency of clients.

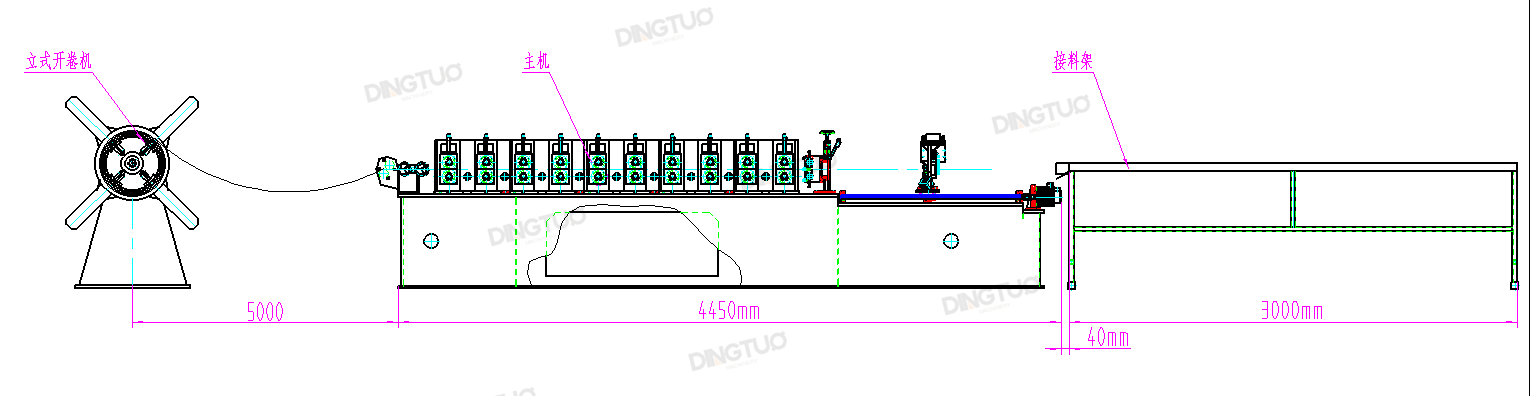

Machine Schematic

|

NO. |

Description |

Quantity (set) |

|

1 |

1.5 T/2.5T/3T...customized(manual/hydraulic/electric) decoiler |

1 |

|

2 |

Feeding Platform |

1 |

|

3 |

Forming system |

1 |

|

4 |

Transmission system |

1 |

|

5 |

Automatic Hydraulic Cut |

1 |

|

6 |

Run-out table |

1 |

|

7 |

Hydraulic pump station |

1 |

|

8 |

Electric Control Cabinet |

1 |

|

9 |

Spare parts and tools |

1 |

Firstly, the production line includes :

one passive Decoilers (pay attention,free to send you)

Roll Forming Machine(pay attention, this is the host roll forming machine )

one run-out tables (pay attention,free to send you )

Machine base frame material:

Whole steel plate welded about the surface which will be made by CNC machine and surface will have good flatness and looks bright and beautiful.(pay attention: the machine base frame was not welded by square tubes).

Machine forming Station:

12 stations according to your profiles. (pay attention: this is the best suitable forming stations, neither more nor less about the forming stations).

Rollers material:

Cr12 material with turning+quenching(hardness 58-62degrees)+grinding+fine turning treatment which has good quality and this type of processing can guarantee the rollers' hardness meet international standard HRC 58-62 degrees and has good were resistance.(pay attention: the roller material neither made of 45# steels nor bearing steels).

Machine stands (can also choose cast iron machine stands) : cast iron machine stands

Shaft diameter:

60mm diameter solid shafts (pay attention: the shafts are solid and the shaft diameter is 60mm, not 50mm).

Power:

- Main power : 2*7.5 kw

- Automatic size changeable reducer part servo motor power : 2* 1.5kw

- Hydraulic cutting power :7.5kw

- Hydraulic pump station punching motor power : 5.5kw+5.5kw

- Main machine servo tracking none-stop motor power:2.3kw+2.3kw

(41.1kw.h total )

Transmission way :

Gearboxes which has the best stable performance.

Machine uncoiler type : free to send you.

Machine run out table : free to send you .

Voltage:

customized (pay attention : If your voltage is special ( not 380V , 50HZ, 3 phases , we all called special voltage) which means the all motors of the machine need to be customized according to your voltage.So that this part will add some motor customized costs).

Machine Speed:

because some clients profile sizes need perforation, so according to the sizes and gauge , the maximum machine speed included that punching can reach 30m/min. Without punching perforations, the machine can reach 40-45m/min.

|

No |

Item |

Parameter |

|

1 |

Raw Material |

Stainless steel /GI/Aluminum/PPGI , Q235 , 0.4-1mm |

|

1 |

Decoiler |

1. Feeding method: passive feeding 2. Rolling method: manual tightening 3. Suitable coil inner diameter: φ508mm 4. Suitable coil outer diameter:<φ1400mm 5. Load: 1.5/2.5/3/5...customized tons |

|

2 |

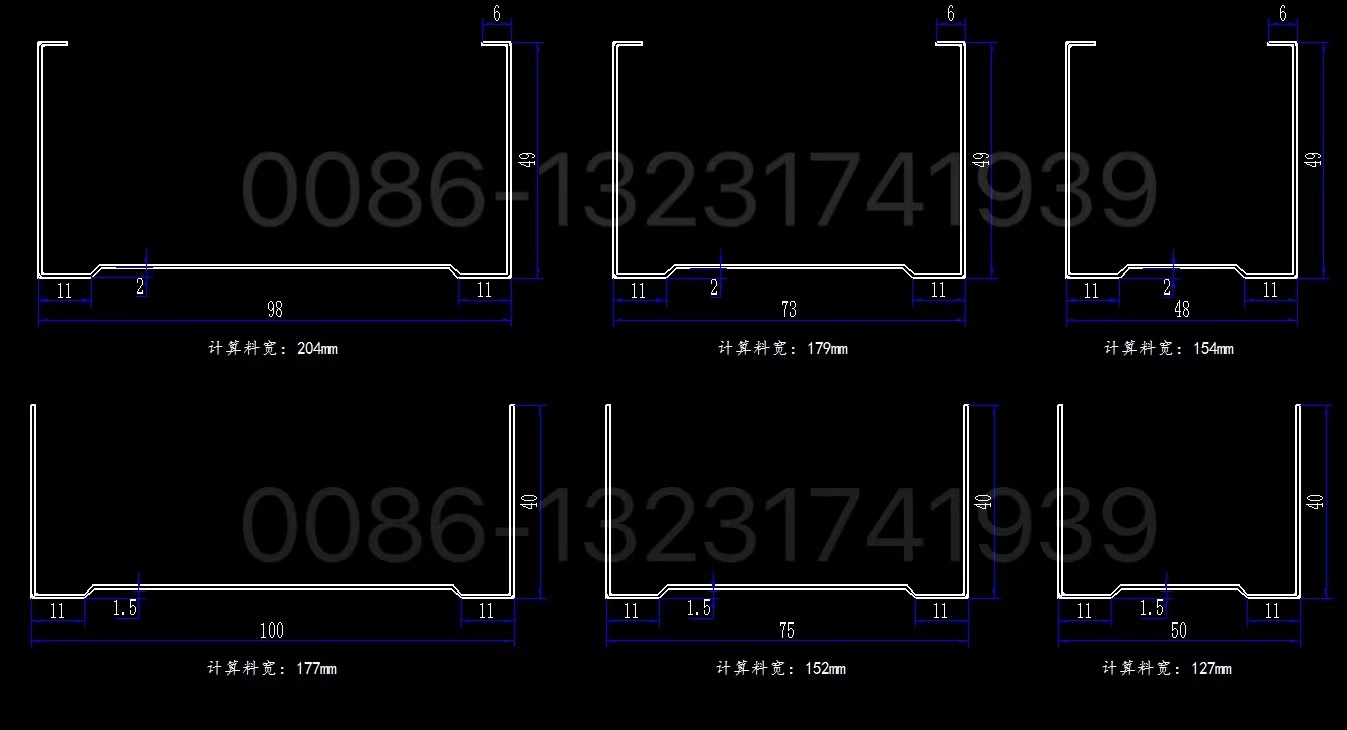

Profile Size |

50 75 100 CU |

|

3 |

Side stands’ |

cast iron |

|

4 |

Forming Speed |

50m/min |

|

5 |

Forming station |

15 |

|

6 |

Total Power |

(41.1kw.h total ) |

|

7 |

Mill bed material |

whole iron plates |

|

8 |

Voltage |

380 V 50HZ 3 phases 220V /415V/ 480V ....customized |

|

9 |

Diameter of shaft |

50mm diameter solid shafts |

|

10 |

Cutting type |

Automatic shear |

|

11 |

Forming Shaft |

Material : 45# steel. Processing technology: quenching and tempering treatment HB210-230 + lathe rough turning + CNC lathe fine turning shape + milling machine processing keyway and round nut stop groove. |

|

12 |

Forming Roller |

Material: Cr12 steel, processing technology: fine turning + wire cutting keyway + surface polishing and hard chrome plating. |

|

13 |

Cutting Blade |

Material : Cr12 processing technology: rough material milling machine processing - vacuum heat treatment HRC58-60 - flat grinding processing end face - wire cutting processing outline - engraving machine fine carving shape. |

|

14 |

transmission |

gearboxes |

|

15 |

Run Out table Length |

3m |

|

16 |

PLC Brand |

DELTA/XINJIE Brand |

|

17 |

Touch Screen Brand(HMI) |

DELTA/XINJIE Brand |

|

18 |

Frequency Brand |

DELTA/XINJIE Brand |

|

20 |

Electrical motor |

Top brand , quality tested, stable Performance. |

|

21 |

Encoder |

OMRON Brand with aluminum bracket |

|

22 |

Low-voltage electrical |

Top brand , quality tested, stable Performance. |

|

23 |

Machine rough size |

L 11m * W 1.8m * 1.7m |

|

24 |

Machine rough weight |

10500 KGS |

|

25 |

Machine with anchor bolts |

can level the machine on the ground |

Spare Part

|

No. |

Name |

Quantity |

Country |

|

1 |

Encoder |

1pcs |

China |

|

2 |

Encoder wheels |

2pcs |

China |

|

3 |

bearings |

2pcs |

China |

|

4 |

sensors |

2pcs |

China |

|

5 |

Oil tubes |

2pcs |

China |

|

6 |

nuts |

5pcs |

China |

|

7 |

Tool Box |

1 Set |

China |

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat