Standing seam roll-forming machine suitable for the building site constraints

Key words:

Product category:

Tel/Whatsapp:

Standing seam roll-forming machine suitable for the building site constraints

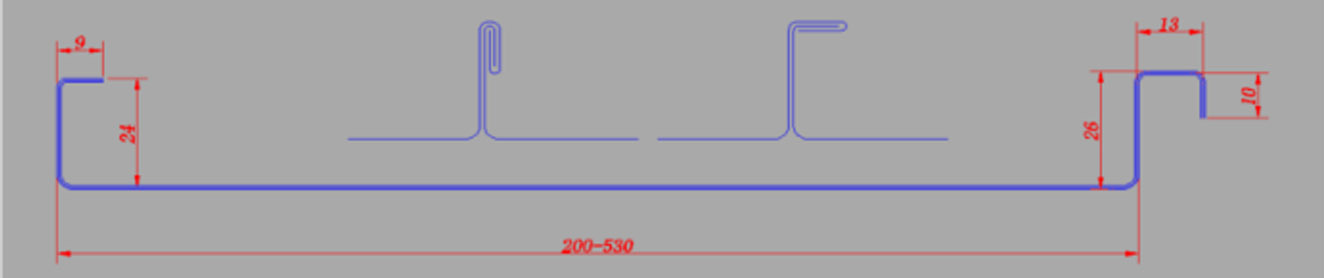

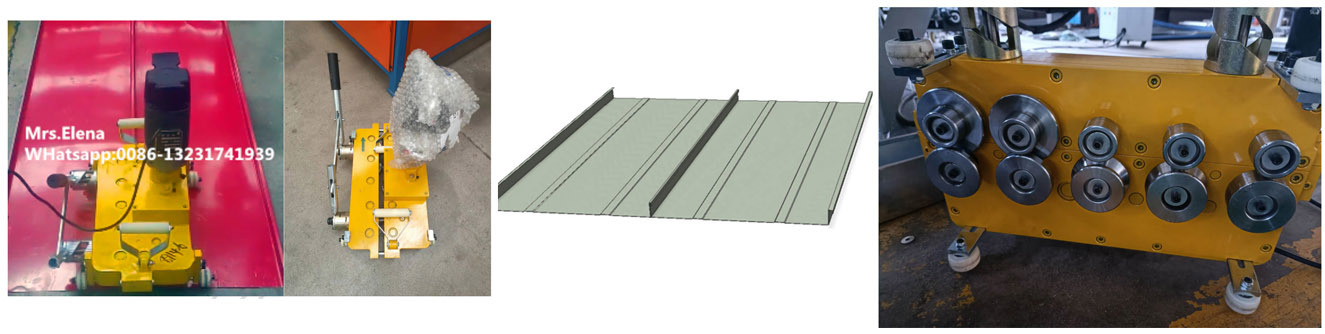

Profile Drawing

(THE MIDDLE RIBS CAN BE CONTROLLED BY YOURSELF TO DO OR NOT TO DO)

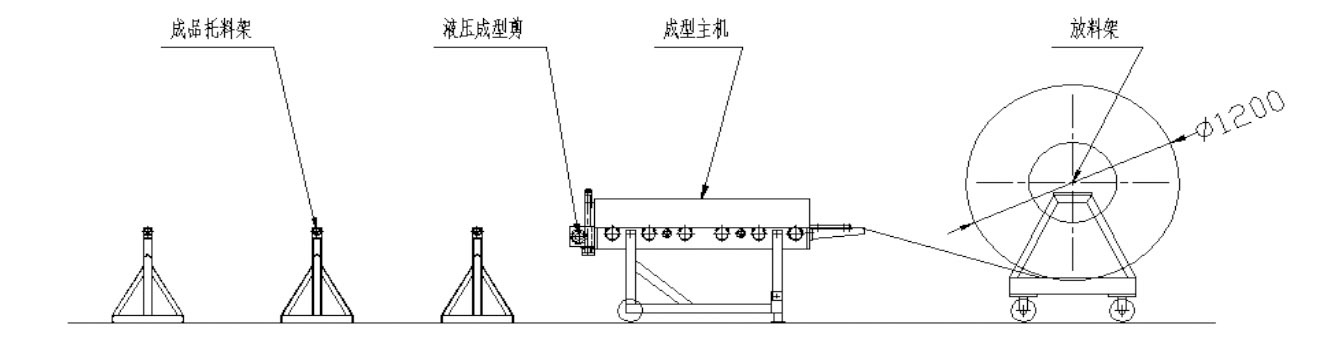

Supplying Components Of Complete Machine

| NO. | Description | Quantity (set) |

| 1 | 3Tmanual decoiler | 1 |

| 2 | Feeding platform | 1 |

| 3 | Forming system with 3 ribs | 1 |

| 4 | Transmission system | 1 |

| 5 | Hydraulic cutting system | 1 |

| 6 | Run out table | 3 |

| 7 | Hydraulic pump station | 1 |

| 8 | Electric control cabinet | 1 |

| 9 | Spare parts and tools | 1 |

Parameters

| No | Item | Parameter |

| 1 | Aluminum thickness | 24 gauge to 20 gauge (0.6-1.0mm) |

| 2 | Steel thickness | 24 gauge to 22 gauge (0.6-0.8mm) |

| 3 | Titanium zinc thickness | 24 gauge to 22 gauge (0.6-0.8mm) |

| 4 | Material strength | Q235mpa |

| 5 | Feeding width | 300mm to 630mm |

| 6 | Sheet bottom width | 200mm-530mm |

| 7 | Forming station | 8 stations + auxiliary forming wheel |

| 8 | Forming Speed | 10m/min with inverter adjusts the speed |

| 9 | Hydraulic cutting motor | 2.2kw |

| 10 | Main drive motor | 2.2KW main motor power with cycloidal pinwheel reducer |

| 11 | Chain | I inches chain, part of upper and lower gears |

| 12 | Shaft diameter | 45mm solid shafts |

| 13 | Shaft material | 45 # steel finishing and the surface is plated with hard chrome and then brushed and polished,surface finish reaches mirror standard |

| 14 | Roller material | 45 # steel finishing and the surface is plated with hard chrome and polished,surface finish reaches mirror standard |

| 15 | Machine base frame | 60*60mm square tube welded |

| 16 | Machine stands thickness | 16mm welded box girder |

| 17 | Drive method | Motor drive, front and rear chain drive, part of upper and lower gear drive |

| 18 | Cutting method | Hydraulic post cutting type |

| 19 | Length counting method | OMRON (JAPAN ) brand encoder |

| 20 | Control method | DELTA brand (TAIWAN,CHINA) PLC / Touch Screen |

| 21 | Operating method | Button +touch screen |

| 22 | Hydraulic Brand | Solenoid Valve Beijing Huade, Taiwan Precision Gear Pump, |

| 23 | De-coiler | bearing weight 3 tons, manual tightening, passive loading |

| 24 | Run out table | 3 pieces |

| 25 | Profile Height | 1’’ |

| 26 | Blade material | Cr12 material with turning+quenching (hardness 58-62degrees)+grinding+fine turning treatment |

| 27 | panels with ribs | YES |

| 28 | Machine size | L 2.7m*W1.5m*H1.6m |

| 29 | Machine Weight | About 1.3 tons . |

Line Components and Characteristic

| Name | Photos | Description |

| 3T Manual Decoiler |  | 1.Power: None 2. Power of the open and closure of segments: Mechanical 3.Power of rotation of segment: Pull by forming system 4.Number of segment: 4 5.Range of segment expansion: 480 ~ 520mm 6.Height of center of the mandrel: 0.65m 7.Feeding speed with push: 0~30m/min 8.Approximate Size: 0.97 m * 0.78m *0.9 m 9.Speed control: By mechanical brake 10.Methods of operation: Manual 11.Quantity:1 set |

| Sheet Guiding Device |  | 1.Features: Ensure smooth& precise material feed. 2.Components: steel plate platform, two pitching rollers, position stopping block. 3. The coil is guided in the correct position and passed to the roll forming equipment. |

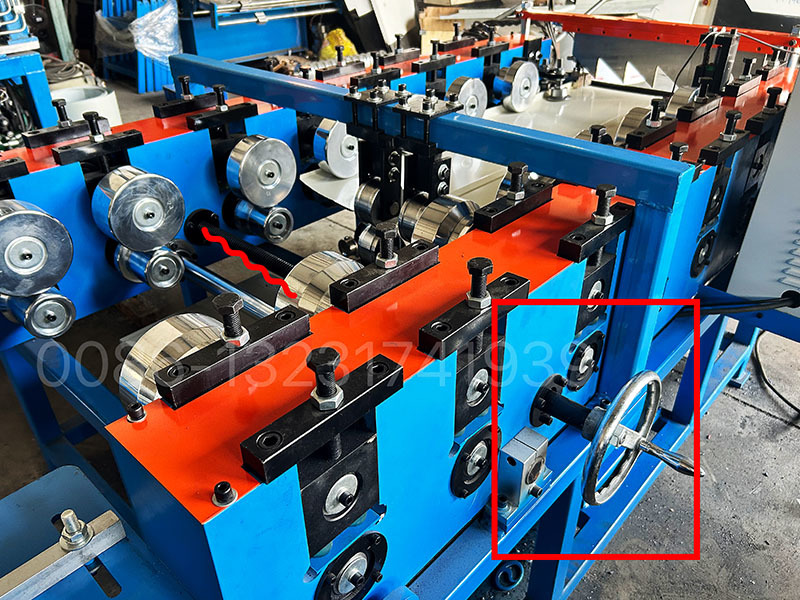

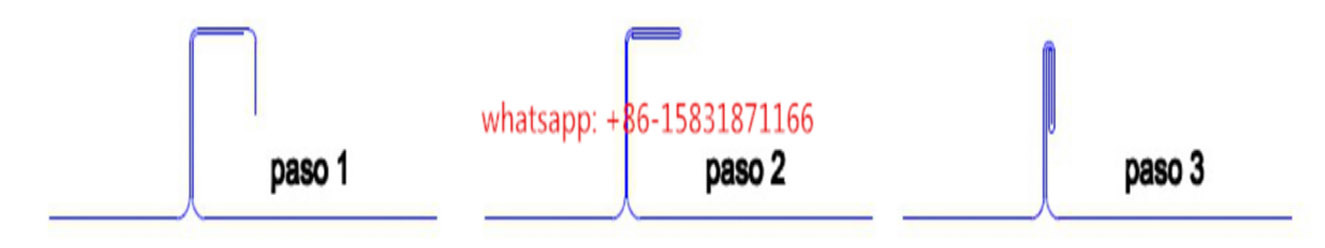

| Forming system |  | 1.Rollers: design by senior engineers with Auto-cad software, manufactured with 45# high grade steel by CNC machine tools and coated with hard chrome 2.Shaft: 45# high grade steel by CNC machine tools 3. Supporting frame: steel wallboard to guide the forming station bearing basement 4.The finished products will change if using different material and thickness 5.Driving of machine:by chain and main motor 6. machine stands’ thickness: 18mm |

| Hydraulic cut without changing baldes |  | 1.Function: cutting action is controlled by PLC. The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start. 2.Power supply: hydraulic station 3.Frame: welding steel frame 4.Stroke switch: non-contact photoelectric switch 5.Cutting before forming: cut the sheet after roll forming to required length 6.Length measuring: automatic length measuring 7. Blade material:Cr12 material with finishing |

| Running Out Table |  | 1.Feature: finish product collection 2.Material: steel frame and nylon shaft 3.Qty: 3 sets |

| Main motor |  |

|

| Hydraulic System |  | 1. Adopted top brand hydraulic system components to ensure the stability and lifetime, avoid leakage. 2. Supplies the initial power to the cuter through a closed oil tank. It is off without cutting, which can save the power. 3.Power of motor:2.2 kw |

| Electric Control System |  | The whole line is controlled by PLC and touch screen. The PLC system is with high-speed communication module, it is easy for operation. The technical data and system parameter can be set by touch screen, and it is with warning function to control the work of whole line. 1.Control the cutting length automatically 2.Automatic Length measurement and quantity counting (precision 3m+/-3mm) 3.Voltage:220V, 1 Phase 60Hz / 380V 50HZ 3 phases ( phases and voltage can be customized as your needed) |

Related Machines

Standing Seam Machine Seamer Effects 360 degrees seamer effects

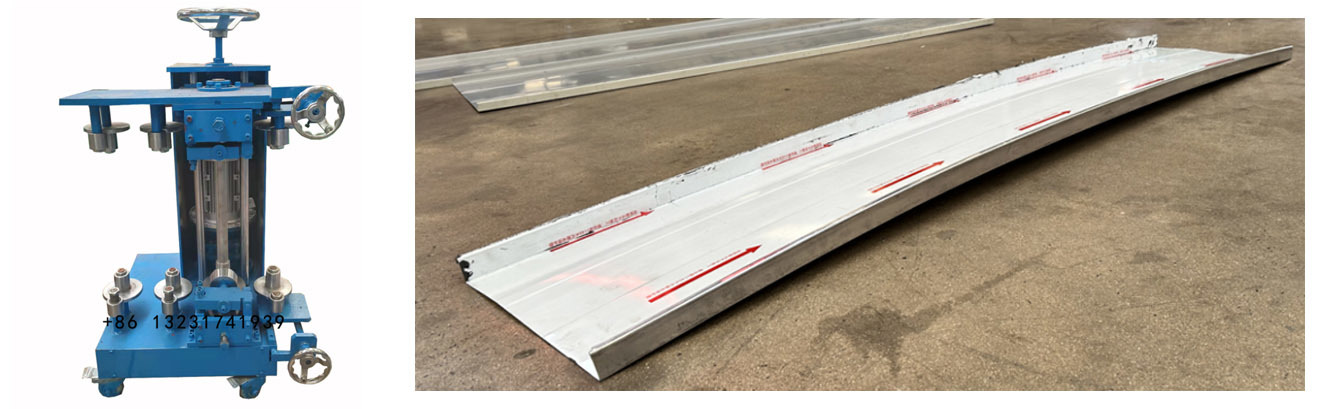

Simple Electric Curving Machine

| MACHINE PARAMETER | ||

| No | Item | Parameter |

| 1 | Material | Steel plate |

| 2 | Thickness | 22 gauge (0.55mm) 24 gauge(0.6mm) 26gauge(0.65mm) |

| 3 | Profile’s height | 1.5 inch |

| 1 | Motor power | 2.2KW |

| 2 | Drive By | Chains |

| 3 | Roller Molds | 4 pairs |

| 5 | Minimum radius of arc (1 inch ) | More than 10m |

| 6 | Control | By Electric Motor and by manual |

Spare parts(for free)

| No. | Name | Quantity | Country |

| 1 | chain | 1pcs | China |

| 2 | bearing | 2pcs | China |

| 3 | Travel switch | 2pcs | China |

| 4 | Relay | 2pcs | China |

Package

1). Container packing of the line suitable for overseas shipping

2). The subjects can be loaded by LCL shipping which freight is cheap.

3). Package style: Covered by plastic film, spare parts and some small parts packed in carton box.

Delivery Time

30-35days(not include Chinese holiday) from order acceptance, deposit receipt and technical details agreement.

Payment

30% paid by T/T as deposit, 70% paid by T/T before loading.

Quality Warranty

● If you need , we can send engineer to customer’s factory and to install the machine and debug the machine and train the customer’s workers. Any problems between this operation, we will responsible for it until the machines can run well. ( all engineer oversea costs need clients to take: customer needs to pay the expense of round air tickets charge , visa charge, food & accommodation and pick up charge for engineer, debugging charge. Debugging charge can be discussed by both of our parties after machine delivery.

● The quality of main forming part will be guaranteed within 12 months after the machine delivery.

● Within quality guarantee period, except for failures caused by human error and If the electrical machinery, the auto computer are damaged because the buyer’s wrongly operating, wrongly connecting electrical lines or rain, the buyer will be responsible for it. ( This rarely happens, we will give customers the most worry-free installation and wiring method. We send engineers to help you install and debug the machine, and this is unlikely to happen)

● If have any problems caused by machine quality itself(decoiler, host forming machine, cutting, electric control cabinet, hydraulic pump station, run out table....all related with the machines we sold) , within quality guarantee period, repair parts will be provided for free.

● After the quality guarantee period, only charge the production cost of the spare parts and international courier shipping costs.

● Free technical supporting and maintenance consulting in lifetime.

● The seller will offer the machine’s wiring diagram, oil circuit diagram, foundation diagram, operation video, operation manual after the machine finished.

● The buyer can video with the seller at any time. After the buyer receives the machine, the two parties can video communicate the location of the machine. If the buyer needs, the seller will provide assistance at any time.

This advanced standing seam forming machine is engineered for high-precision, continuous production of structural roof and wall panels from coil stock. It efficiently processes a range of materials including aluminum (0.6-1.0mm), steel (0.6-0.8mm), and titanium zinc (0.6-0.8mm), with a maximum feeding width of 630mm. The machine features a robust 8-station forming system with auxiliary rollers, powered by a 2.2KW main motor and a cycloidal reducer, ensuring stable operation at speeds up to 10m/min. A key highlight is the customizable rib formation, allowing operators to selectively engage the middle ribs for tailored panel profiles. The integrated hydraulic cutting system, controlled by a Delta PLC and touch screen interface, delivers accurate, burr-free cuts to the required length, measured precisely by an Omron encoder.

The machine's durability is guaranteed by its heavy-duty construction, featuring 45mm hard-chrome-plated solid shafts, mirror-finished rollers, and a frame built from 16mm welded box girders. The complete line includes a 3-ton manual decoiler, feeding platform, and three run-out tables, facilitating a smooth and efficient workflow from coil loading to finished panel collection. Designed for ease of operation and minimal maintenance, this machine is an ideal solution for metal workshops and construction material manufacturers seeking to produce high-quality, consistent standing seam panels for modern architectural applications.

Key Features & Components:

Customizable Forming: The forming system allows operators to control the middle ribs, enabling the production of panels with or without these structural elements as required.

Robust Construction: Built with 45 steel, hard-chrome-plated shafts and rollers, and a 16mm thick stand for long-term reliability and precise forming.

Precision Control & Cutting: Delta PLC and touch screen control the entire operation, with an Omron encoder ensuring accurate length measurement and a hydraulic system performing clean, automatic cuts.

Versatile Material Compatibility: Capably forms aluminum, steel, and titanium zinc coils within a thickness range of 0.6mm to 1.0mm.

Complete Production Line: Supplied as a full system including decoiler, forming mainframe, hydraulic cutter, run-out tables, and electric control cabinet.

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat