High intelligence high speed MF1400 C 75 to C 150 1.6mm light gauge steel frame roll forming machine with remote control system

Key words:

Product category:

Tel/Whatsapp:

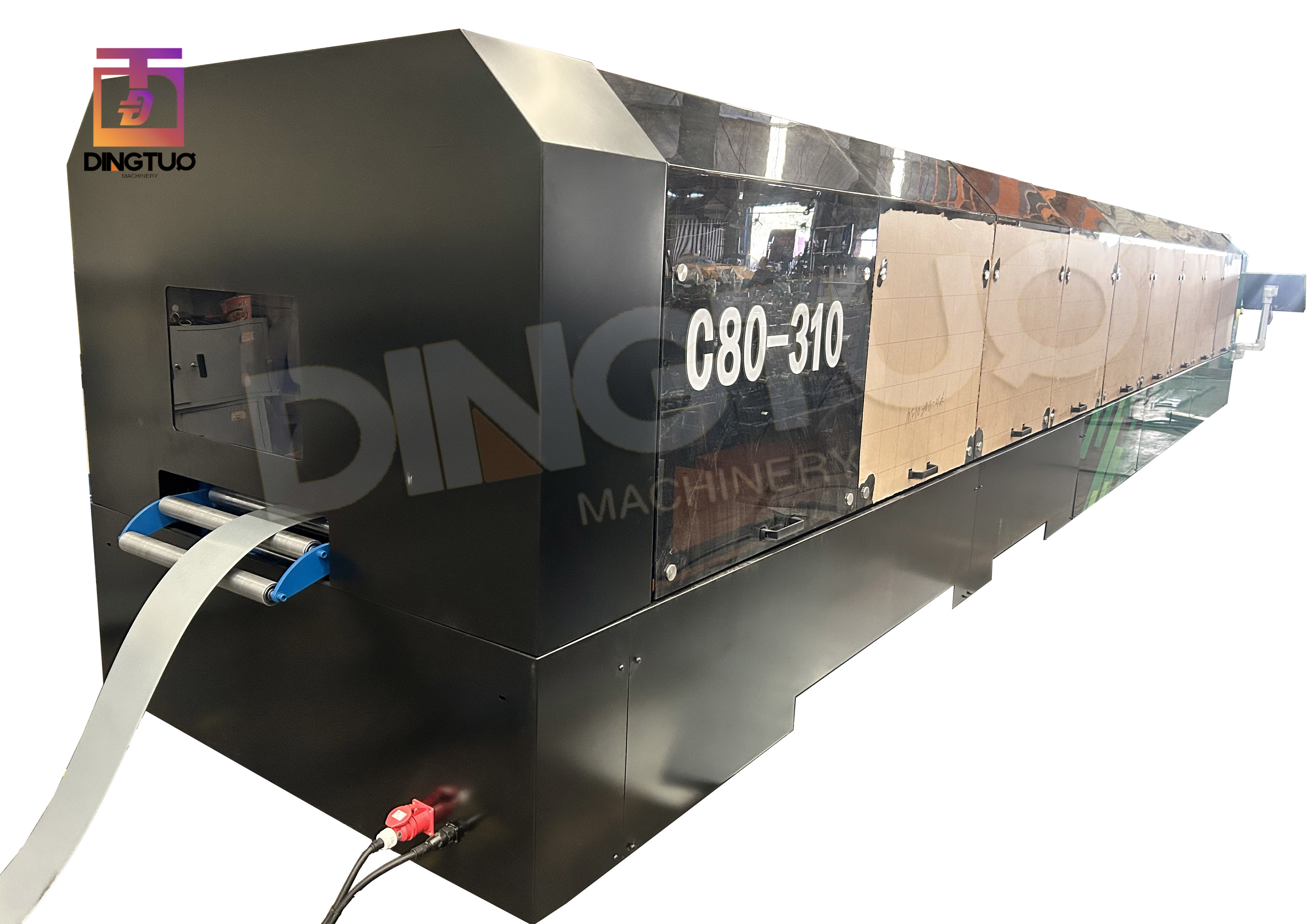

High intelligence high speed MF1400 C 75 to C 150 1.6mm light gauge steel frame roll forming machine with remote control system

LGSF / FLOOR JOIST MACHINE RELATED PRODUCTS

MF1600 C75 TO C150 LIGHT GAUGE STEEL FRAME MACHINE

LGSF PARAMETER :

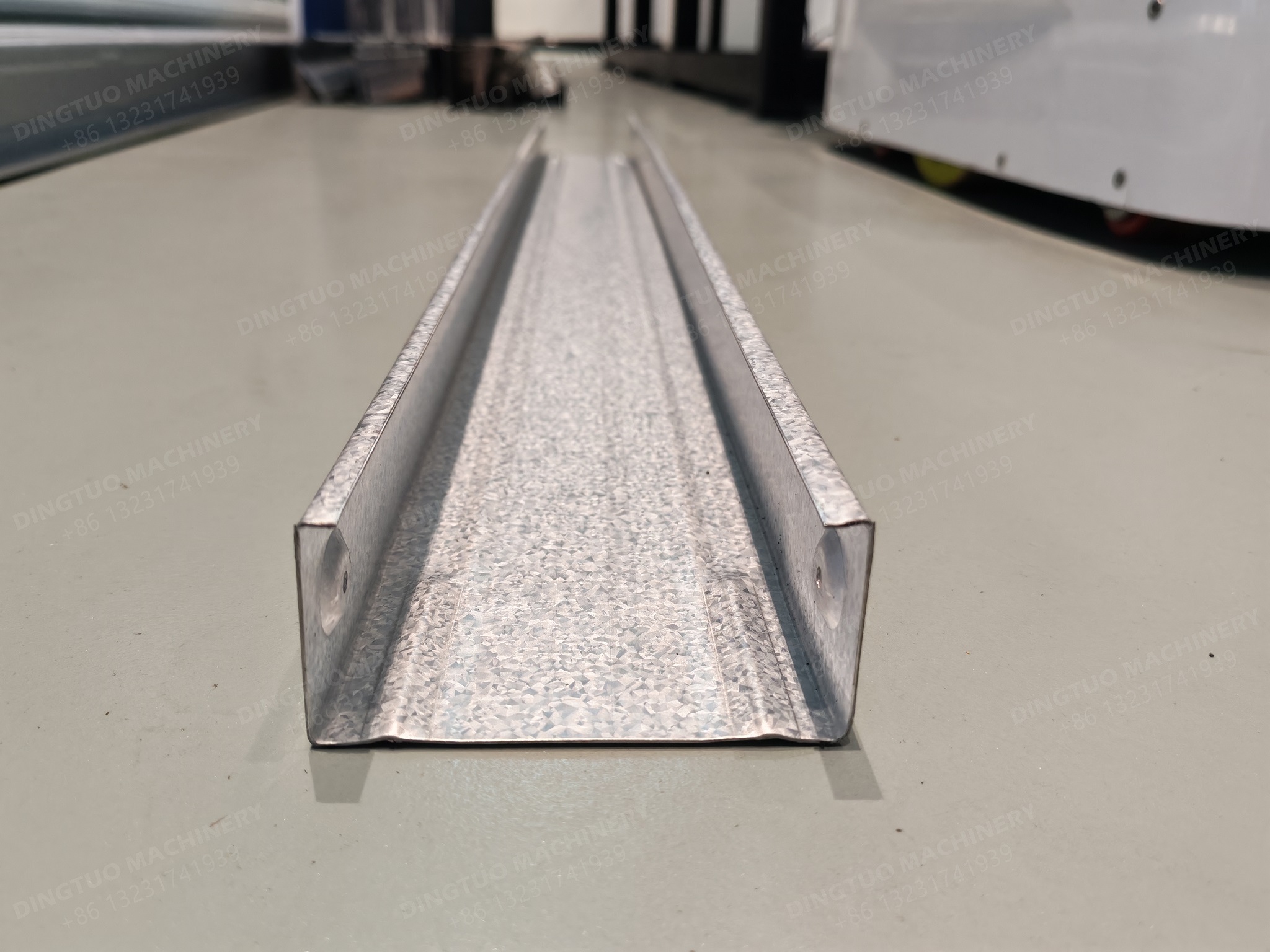

1. Roll-forming width is adjustable between 75 and 160 mm. This agreement includes standard dies: 75 to 92 mm & 126 to 143 mm. Custom sizes are available upon request and subject to additional fees.

2. Waist height: 41 mm.

3. Small side: 8 to 15 mm.

4. Plate thickness: 0.75 to 1.6 mm (adjustable).

5. material : Q235,Q345,G550......

LGSF MACHINE ADVANTAGES:

Popularity: Light gauge steel frame (LGSF) machinery has gained significant traction globally due to its adaptability to modern construction demands, offering cost-effective, sustainable, and time-efficient solutions for residential, commercial, and industrial projects. Its rising adoption aligns with the shift toward green building practices and prefabricated construction.

Architectural Functionality: LGSF systems enable precise engineering of lightweight yet high-strength frameworks, supporting flexible design configurations and excellent seismic resistance. They are ideal for energy-efficient structures, with compatibility for insulation and cladding, while minimizing material waste.

Necessity of Equipment: Specialized LGSF machines are indipensable for manufacturing cold-formed steel components with precision, ensuring structural integrity and compliance with safety standards. These systems enhance production speed, reduce labor costs, and streamline workflows, making them critical for scaling modern construction projects sustainably.

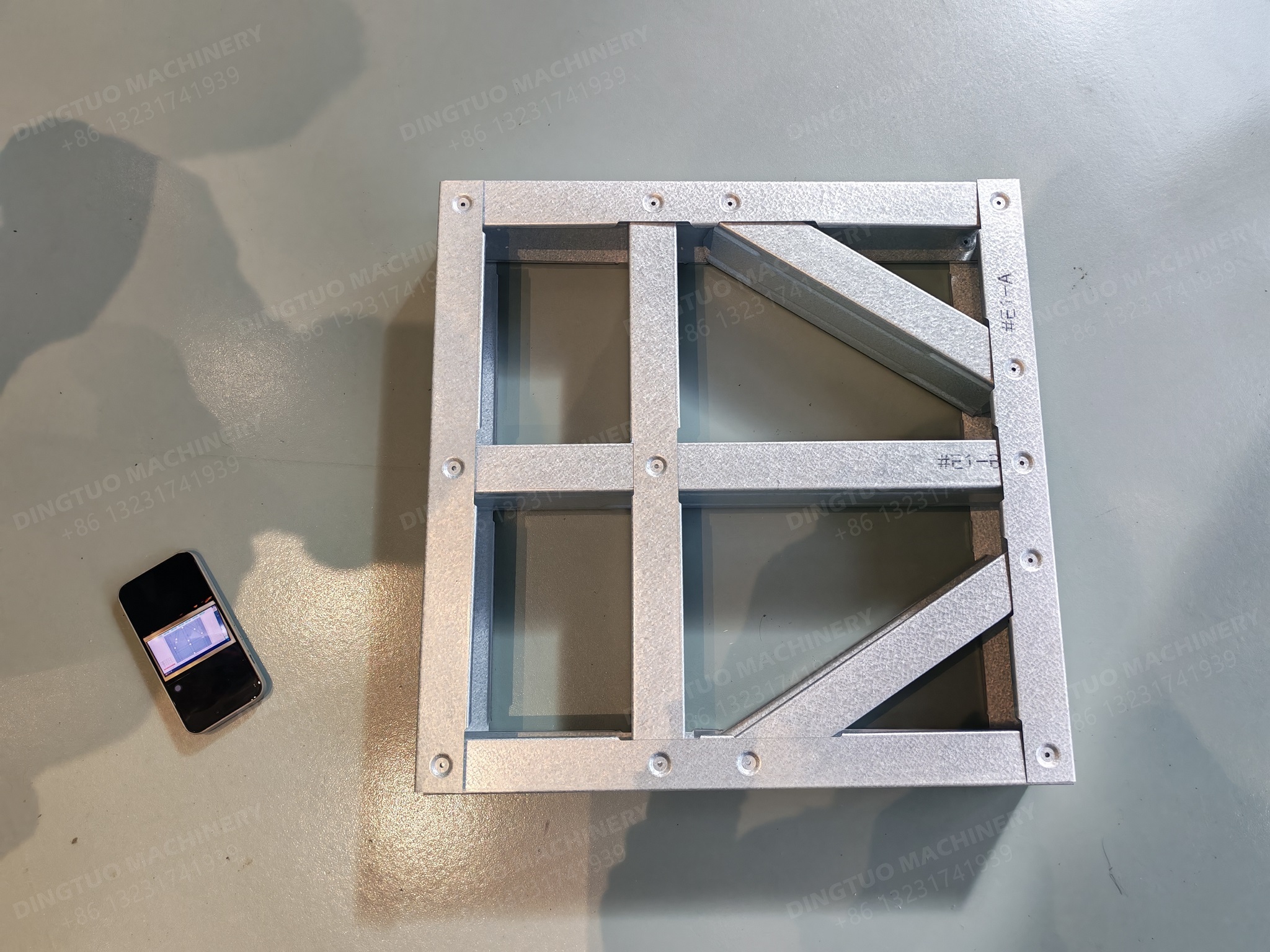

MULTIPLE 75-160 LGSF MACHINE COMPONENTS

1: 3 T ELECTRIC HIGH QUALITY DECOILER

2. FEEDING PLATFORM

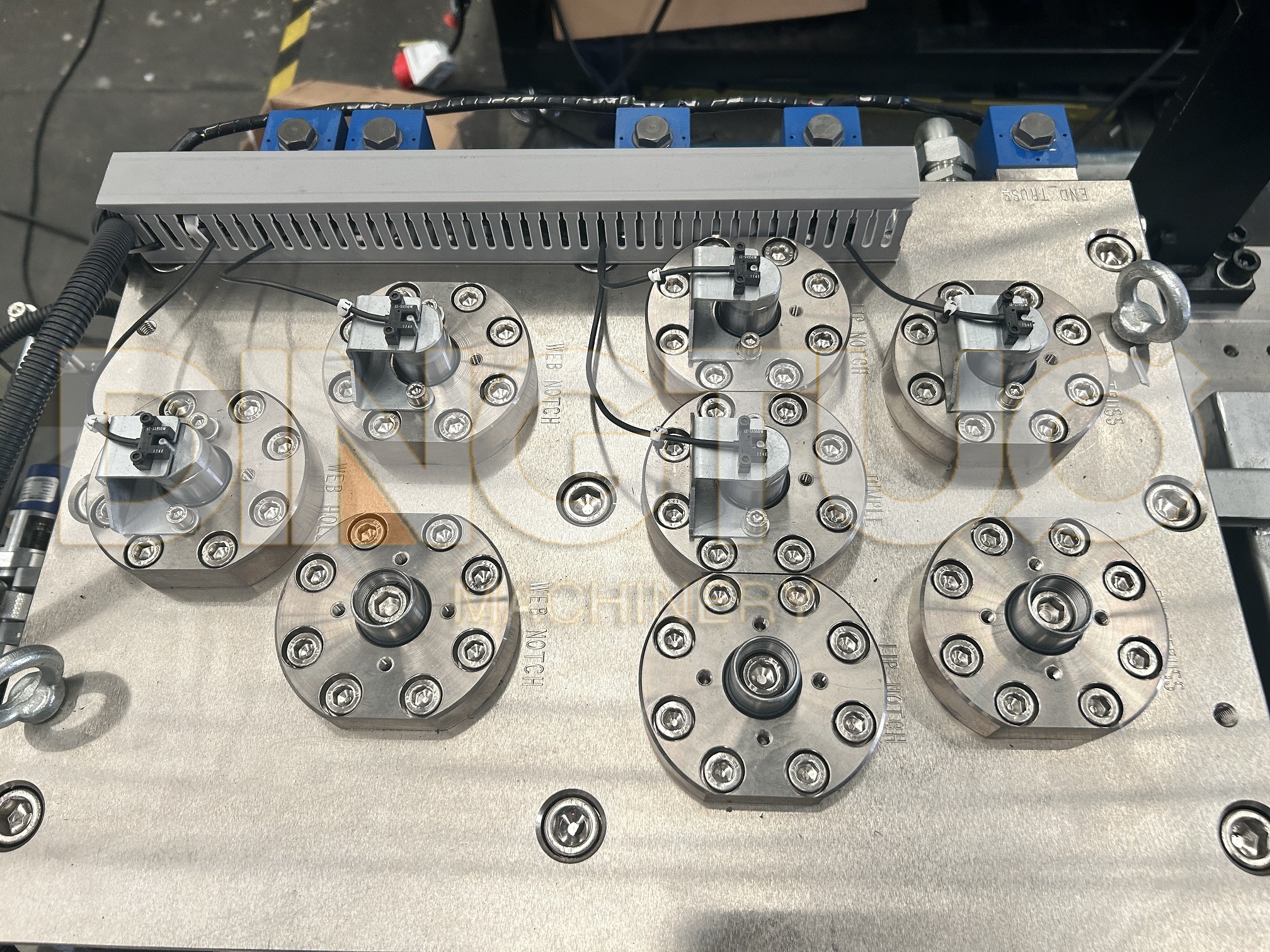

3. STANDARD PUNCHING UNIT ( SUPPORT CUSTOMIZATION)

75-92, 126-143mm any specifications can achieve the following punching:

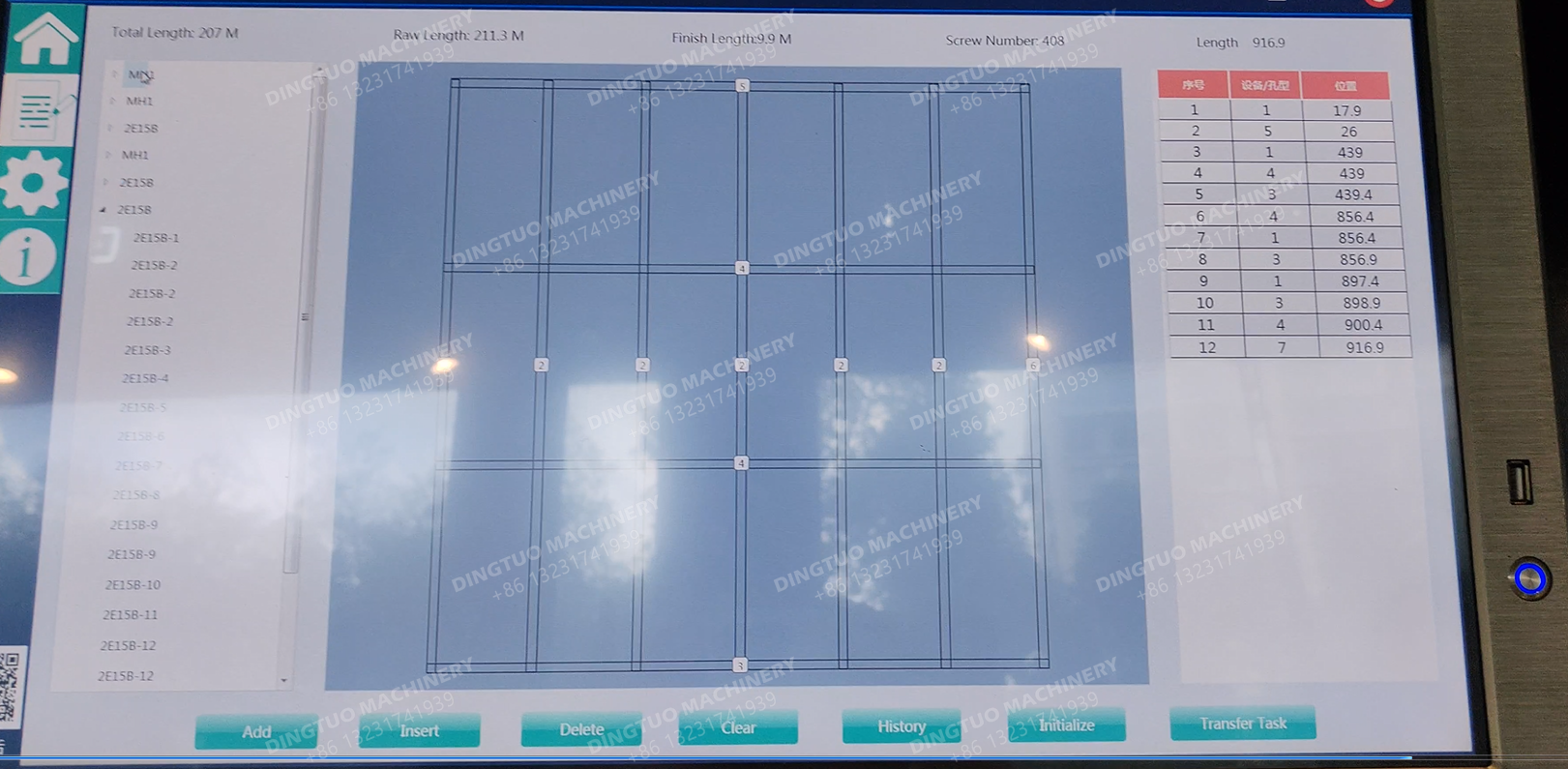

Punching included : 1.service hole 80X40mm ; 2. web notch ; 3. web triple hole 4. web hole 18X22mm 5. dimple hole; 6. lip notch ; 7. end truss (chamfer cut) ; 8. swage ; 9 . flange cut (left ) 10. flange cut (right) 11. cut off

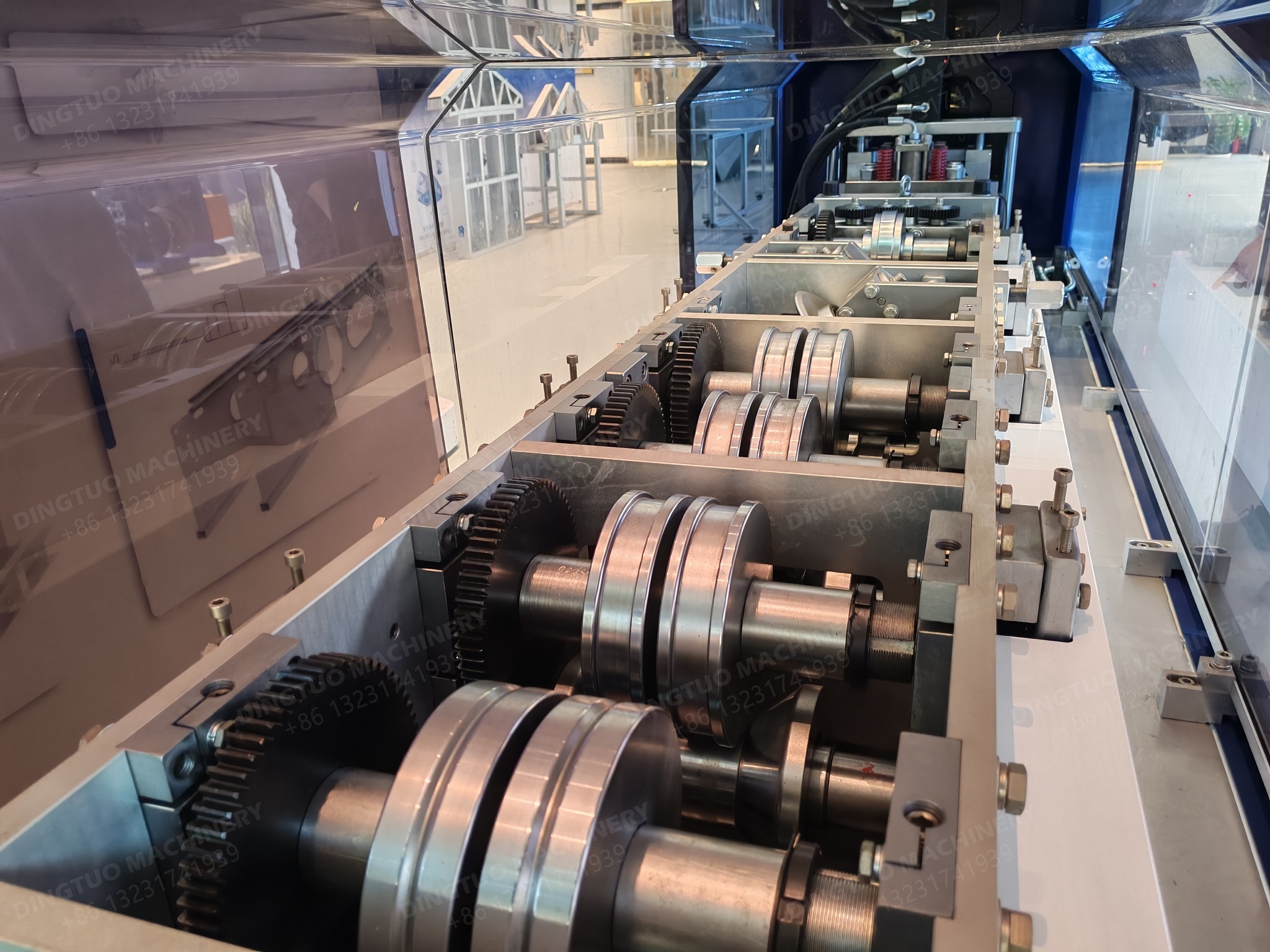

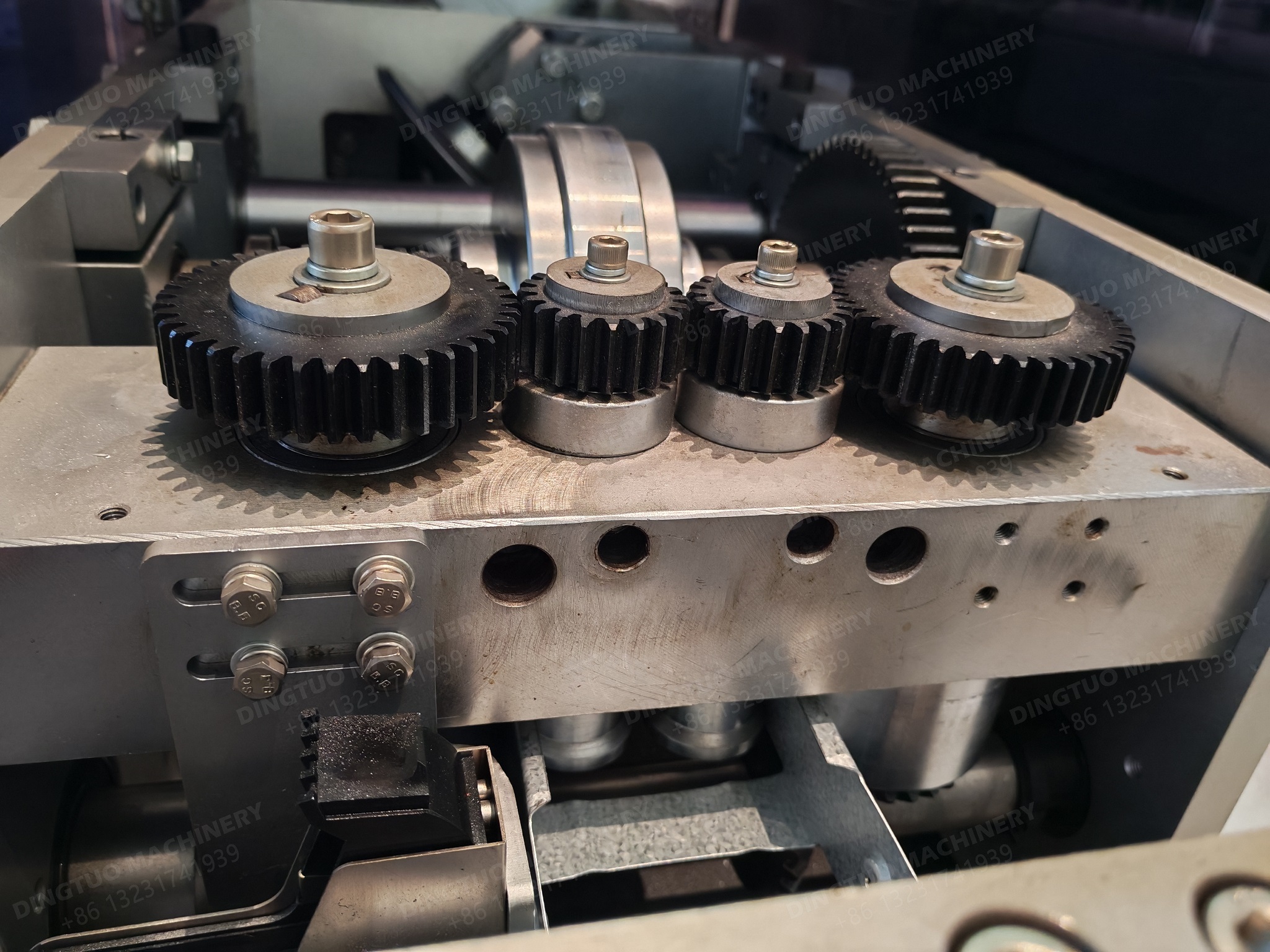

3. FORMING UNIT

The waist-high traction system solves the problem of material jamming. Even with materials with a yield strength of 350Mpa and dense punching conditions, the machine can still run smoothly without jamming.

High-precision roller design ensures the gap between the roller and the material, the profile is not exposed, the shape is neat and beautiful, and it is convenient for plug-in assembly between light gauge steel frames

4. HYDRAULIC PUMP STATION SYSTEM AND ELECTRIC CONTROL SYSTEM

Dual accumulators ensure high-speed 48m/min , stable operation and punching performance.

High-power servo motors and a high-power oil pump station ensure high-speed 48m/min , stable operation and punching performance.

Twenty years of technical experience in the light steel keel equipment industry ensures high-quality, stable operation.

Machine computer program + computer remote program + machine electronic control program + design software are all independently developed to ensure the quality of equipment software and hardware and provide customers with the most powerful service support.

5. RUN OUT TABLE

we can send you run out table production files and you can do it by yourself.

6. SPARE PARTS

some free spare parts will be sent with machine together.

connect Elena to purchase important necessary spare parts .

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat