2 in 1 U shape rolling shutter door guide roll forming machine with production simultaneously

Key words:

Product category:

Tel/Whatsapp:

2 in 1 U shape rolling shutter door guide roll forming machine with production simultaneously

2 in 1 U shape rolling shutter door guide roll forming machine with production simultaneously

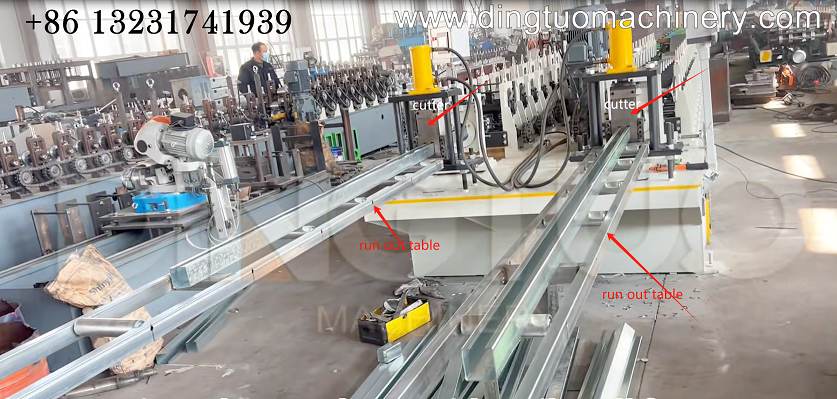

Introducing a versatile cast iron type 2-in-1 metal rolling door guide roll forming machine, designed for simultaneous production. This advanced equipment automates the entire process, transforming coils into shutter slats with ease. The machine features adjustable speed settings, allowing for optimal performance tailored to specific requirements. Essential components of the system include a decoiler, feeding guide, roll forming unit, hydraulic cutting mechanism, and an output table. Remarkably, the entire production line can achieve a maximum working speed of 15 meters per minute, with customization options available for speed adjustments. This machine is engineered to handle iron sheets with a thickness ranging from 0.5 to 1.2 mm, ensuring efficiency and precision in every operation.

Production Line Components :

NO. | Description | Quantity (set) |

1 | 3T manual decoiler | 2 |

| 2 | feeding unit | 2 |

3 | forming unit | 2 |

4 | Leveling unit | 2 |

| 5 | Cutting Unit | 2 |

6 | 3 meters Run out table | 2 |

1. Decoiler

a. Inner diameter of the material roll: ¢500mm; Inner diameter expansion and contraction range: ¢400--¢520mm

b. Maximum outer diameter of the material roll: ¢1200 mm; Maximum load-bearing weight: 3T

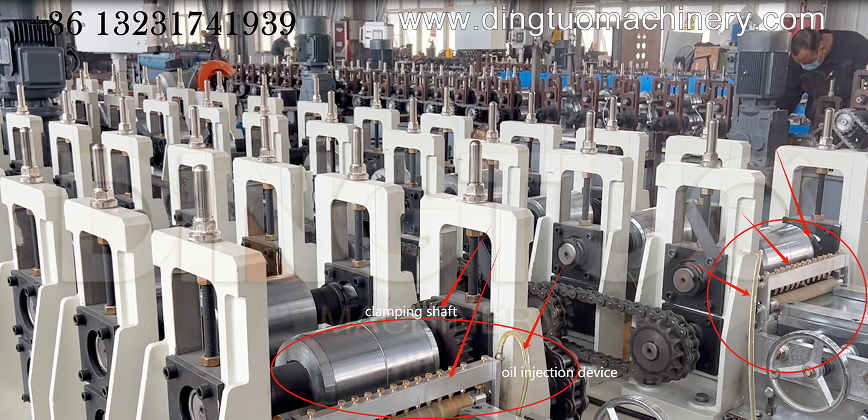

2. FEEDING UNIT

Oil injection device to prevent scratches on the profile surface

The pinch shaft is equipped with gears to better help the material feed into the forming machine

3. FORMING UNIT

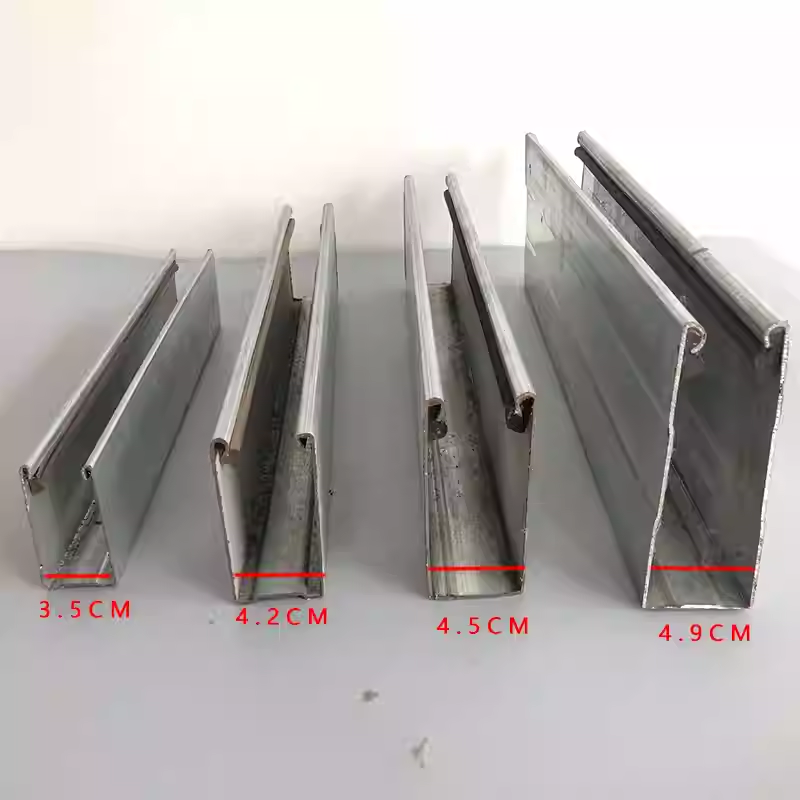

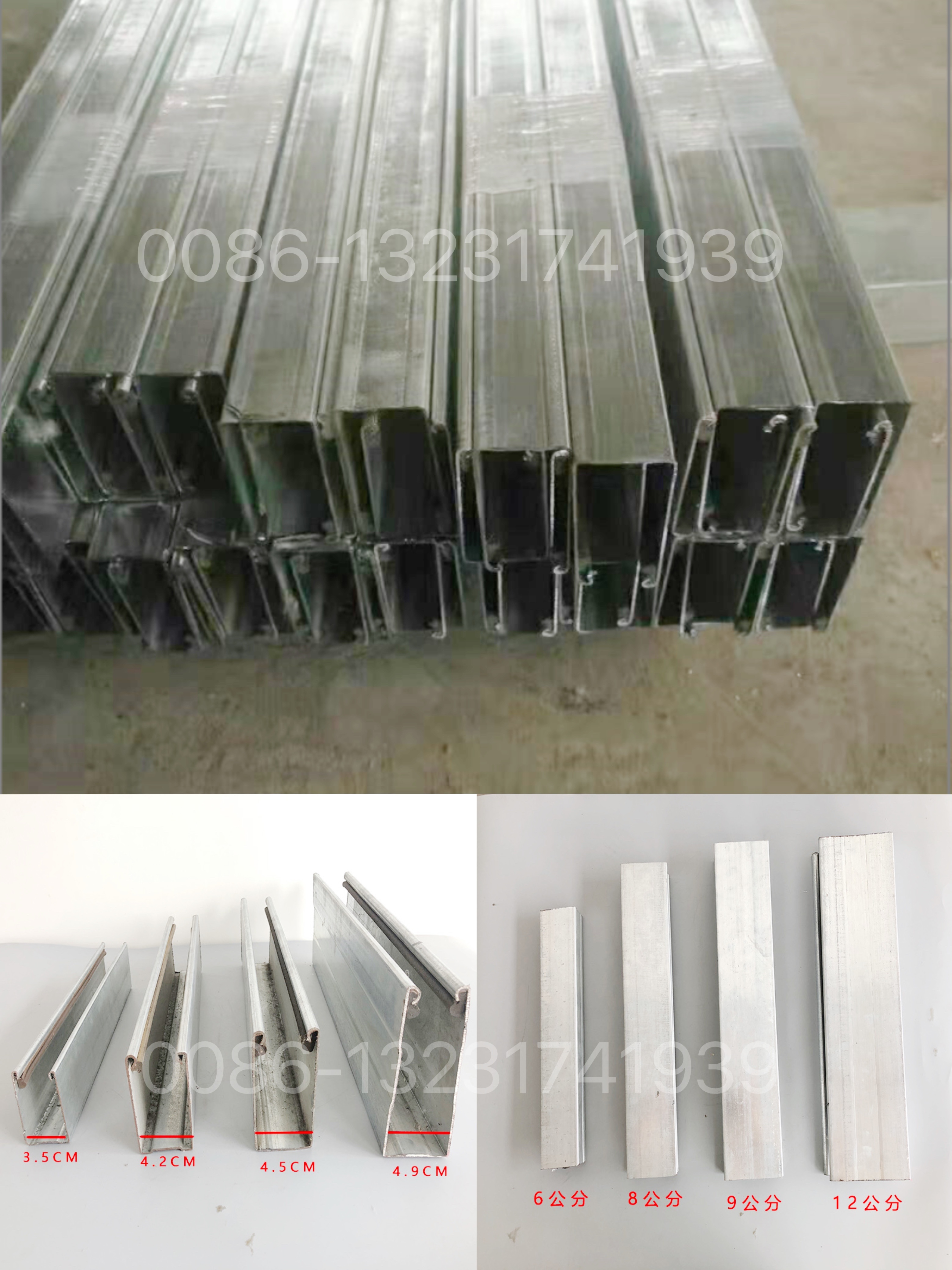

a. Purpose: The forming machine is used to form the guides to the required profile.

b. Function and structure: The shutter slat guide is rolled through 18 forming stations

c. The roller is made of Gcr15 # steel, which is CNC machined after overall quenching. The hardness can reach HRC58-62°. It has the advantages of high strength, high hardness, high precision and long service life.

d. Main machine frame: whole iron plates welded ,Iron Plates with CNC machined.

e. Forming passes: 18

f. Forming frame: cast iron machine stands, chain transmission.

g. Roller shaft diameter: ¢40mm. Material: 45# steel.

Processing technology: quenching and tempering, rough machining, fine machining.

h. Roller die material: 45# steel.

Processing technology: rough machining, heat treatment, fine machining. Quenching hardness: HRC55-58°

i. Main drive motor: double 7.5kw

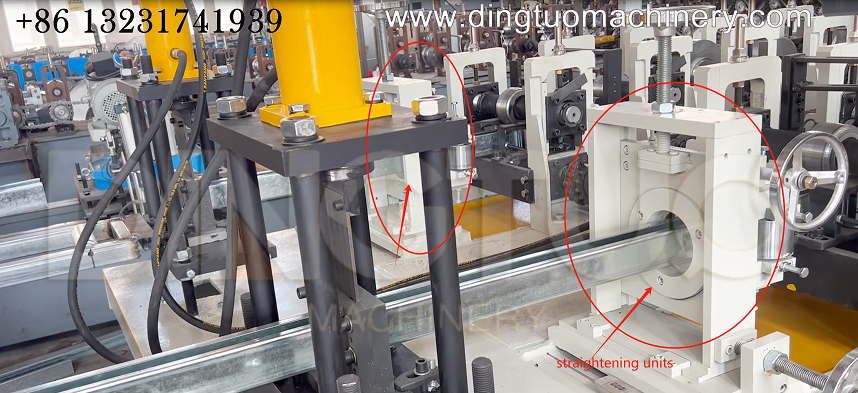

4. STRAIGHTENING UNIT

Straighten length to prevent twisting

5. CUTTING UNIT AND RUN OUT TABLES

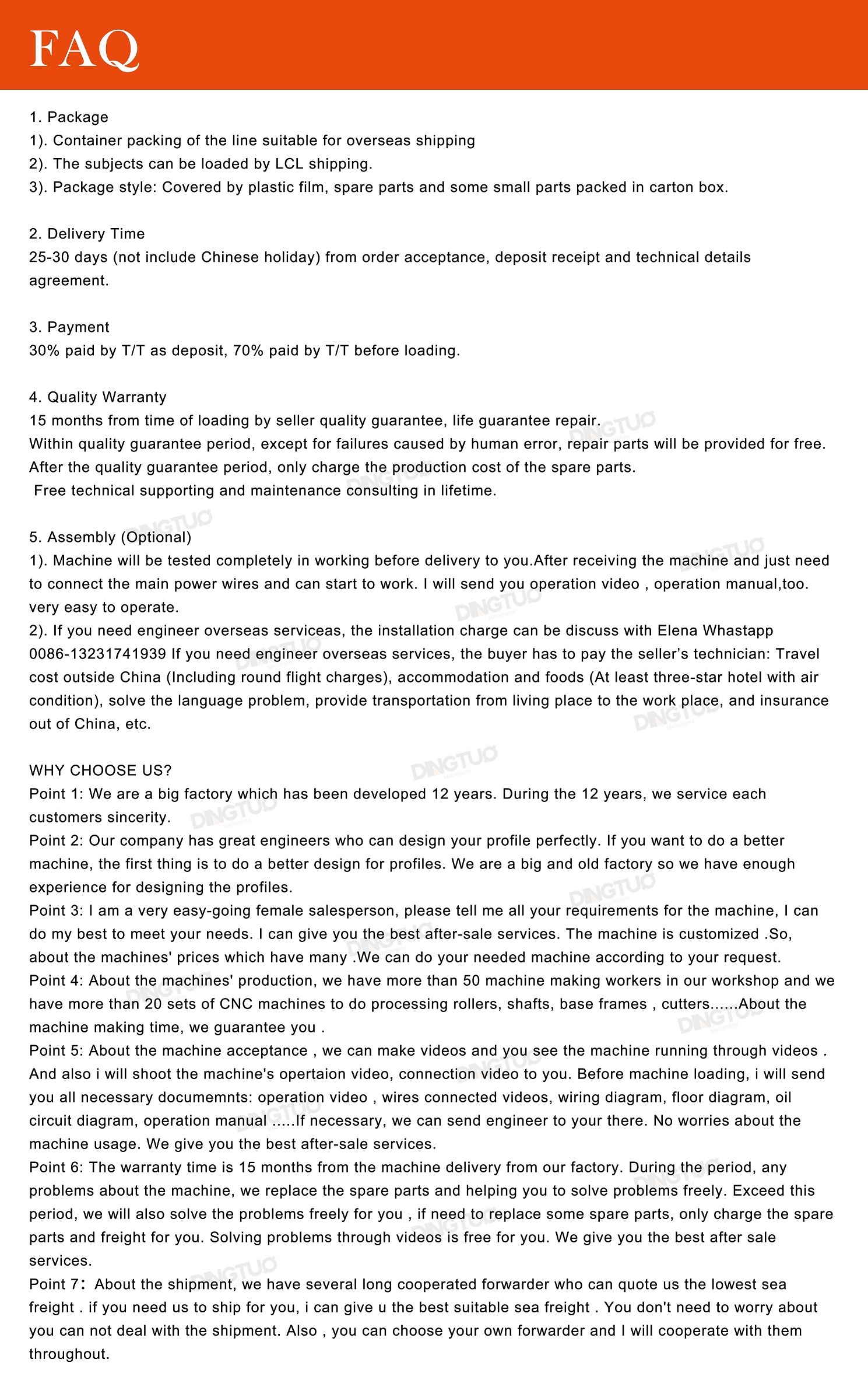

Spare Part

No. | Name | Quantity | Country |

1 | Rely | 2pcs | China |

2 | Encoder | 2pcs | China |

3 | Encoder wheels | 2pcs | China |

4 | bearings | 2pcs | China |

5 | limit switch | 2pcs | China |

6 | Switch buttons | 3pcs | China |

7 | sensor | 4pcs | China |

8 | Oil tubes | 2pcs | China |

9 | Gears | 2pcs | China |

11 | circlip | 30pcs | China |

12 | Tool Box | 1 Set | China |

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat