Metal fence post roll forming machine with laser welding

Tel/Whatsapp:

Metal fence post roll forming machine with laser welding

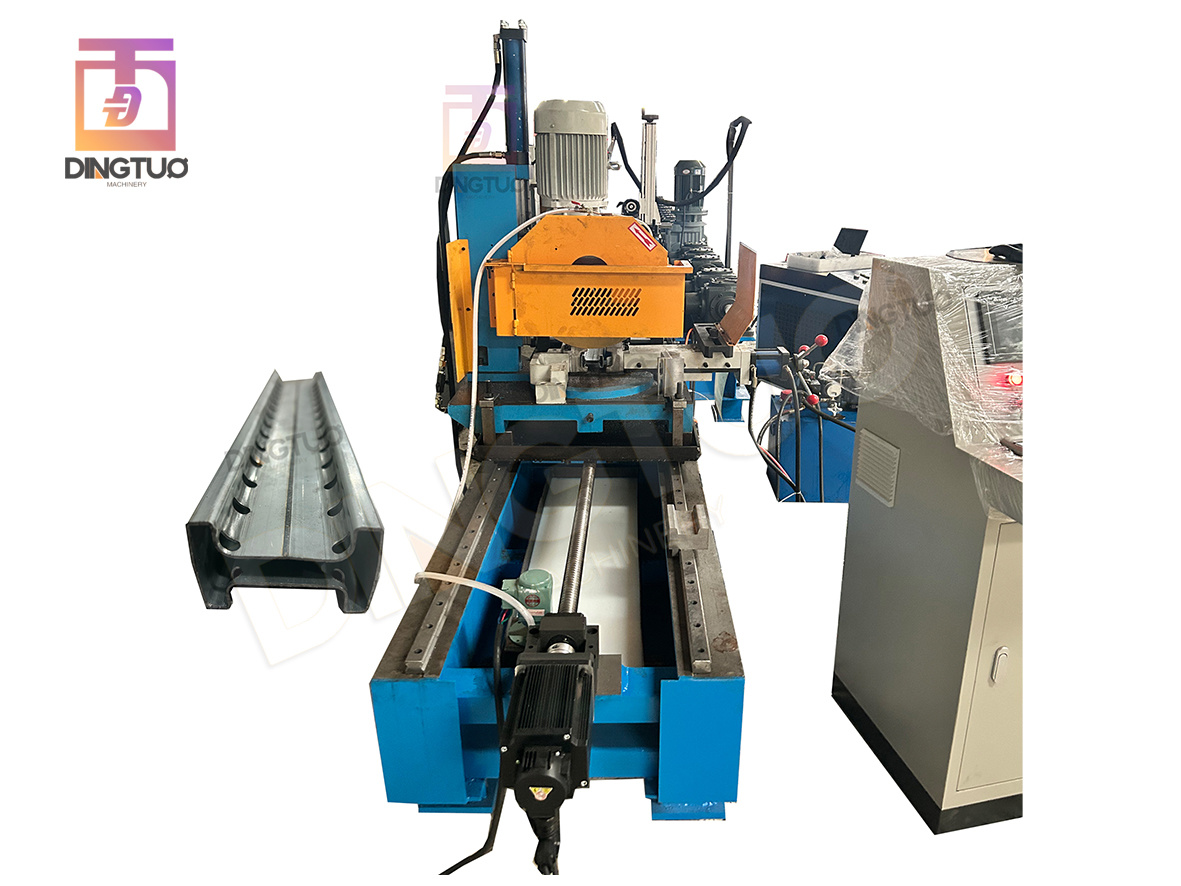

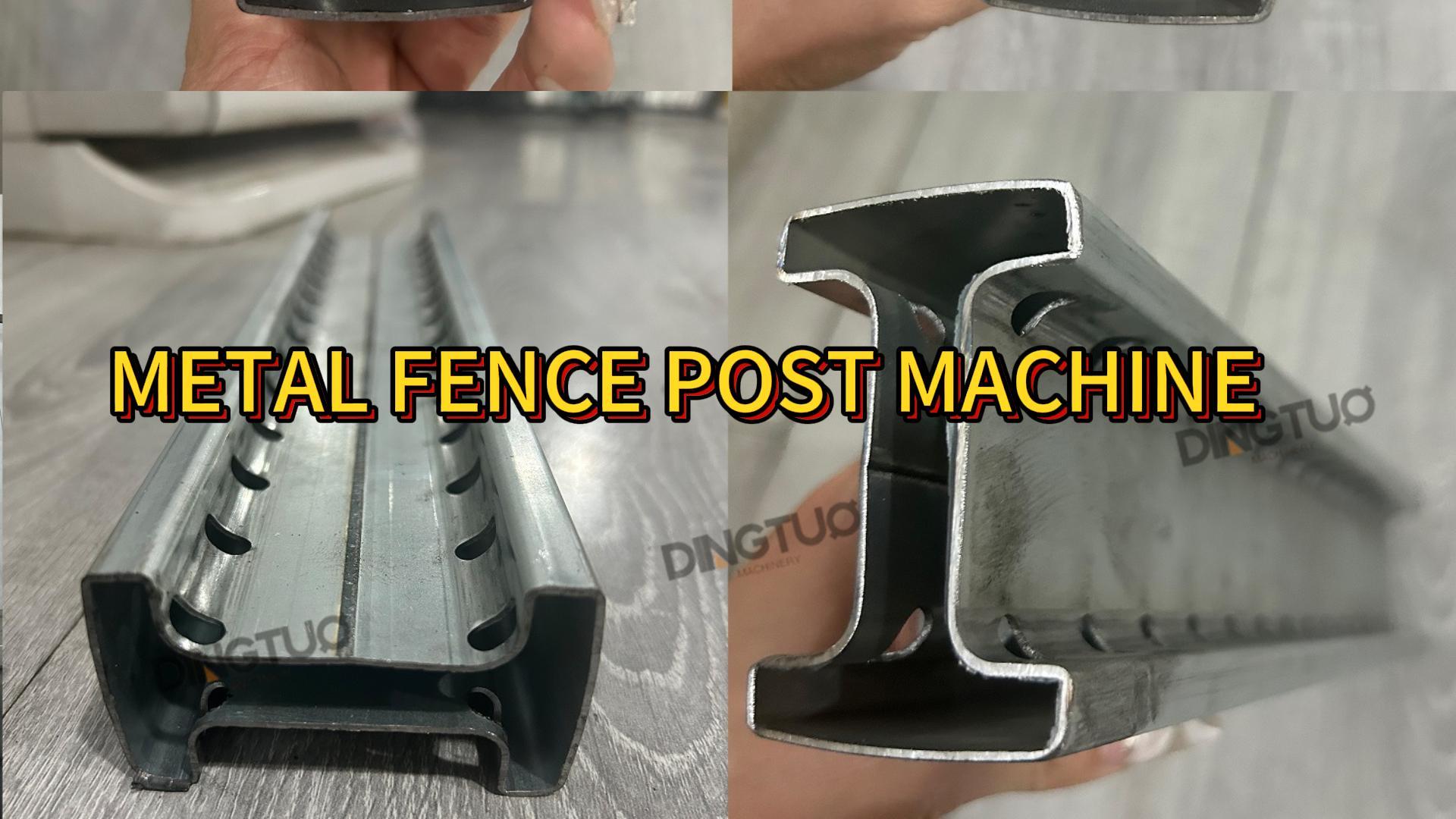

Metal Fence Post Roll Forming Machine

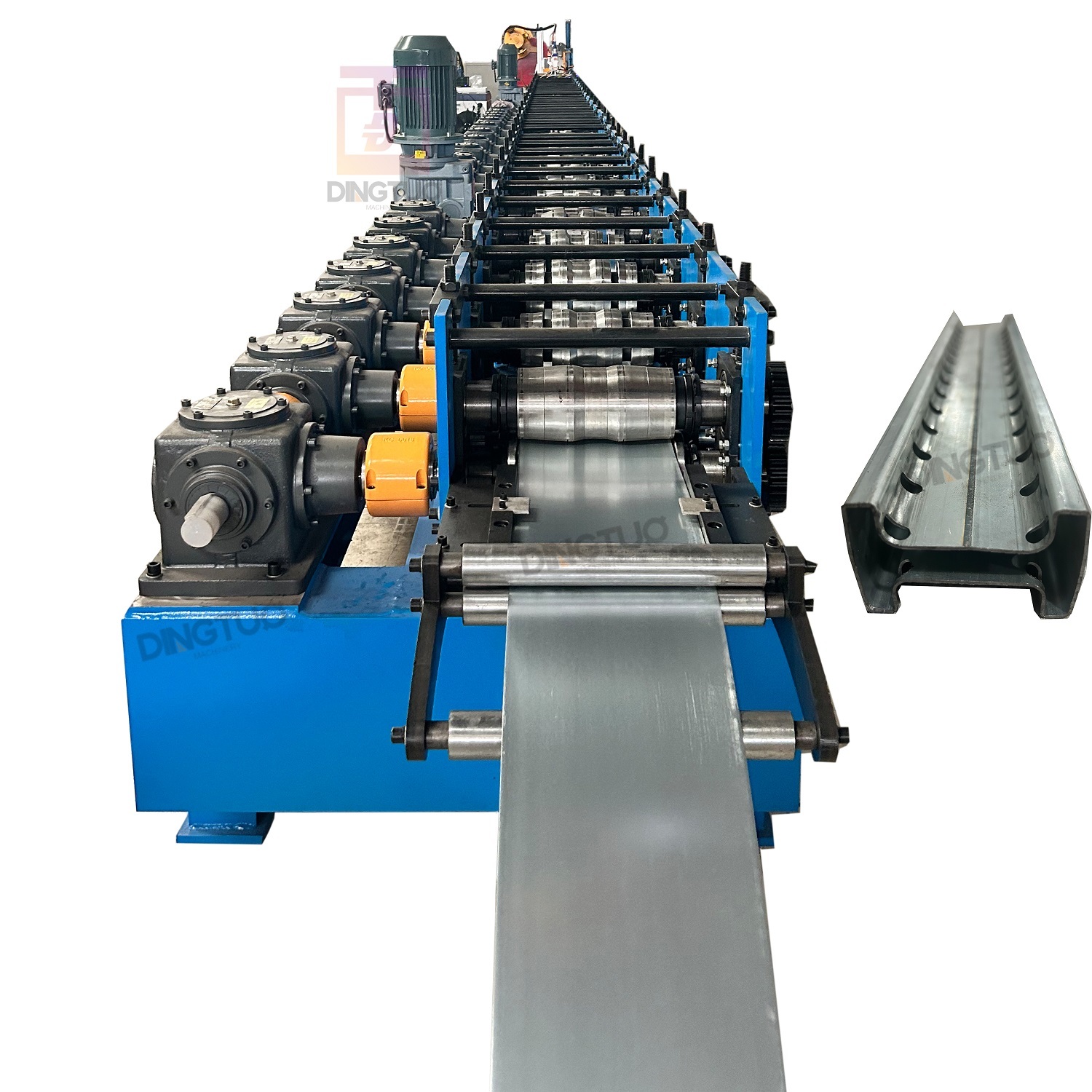

Our metal fence post roll forming machine is designed for fast and efficient production of fence posts with high precision and quality. With the innovative online laser welding and flying cut technology, this machine is able to produce fence posts at a faster speed compared to traditional methods.

The flying cut mechanism allows for precise cutting of the fence posts to the desired length, ensuring uniformity in the final product.

With this advanced technology, our metal fence post roll forming machine is suitable for large-scale production and can meet the demands of the market efficiently. Whether you are a fence post manufacturer looking to increase production capacity or a contractor in need of high-quality fence posts for your projects, our machine is the perfect solution for your needs.

In conclusion, our metal fence post roll forming machine offers faster speed, precision, and quality in the production of fence posts. Invest in our machine today and take your fence post production to the next level.

Machine Profile Drawing ( customized)

Machine Components

NO. | Description | Quantity (set) |

1 | 2 IN 1 DECOILER AND LEVELING MACHINE | 1 |

2 | 40 TONS PUNCHING MACHINE | 1 |

3 | AUTOMATIC SERVO FEEDER MACHINE | 1 |

4 | PUNCHING MOLD FOR NOTCH AND ROUND HOLE | 1 |

5 | HOST FORMING MACHINE | 1 |

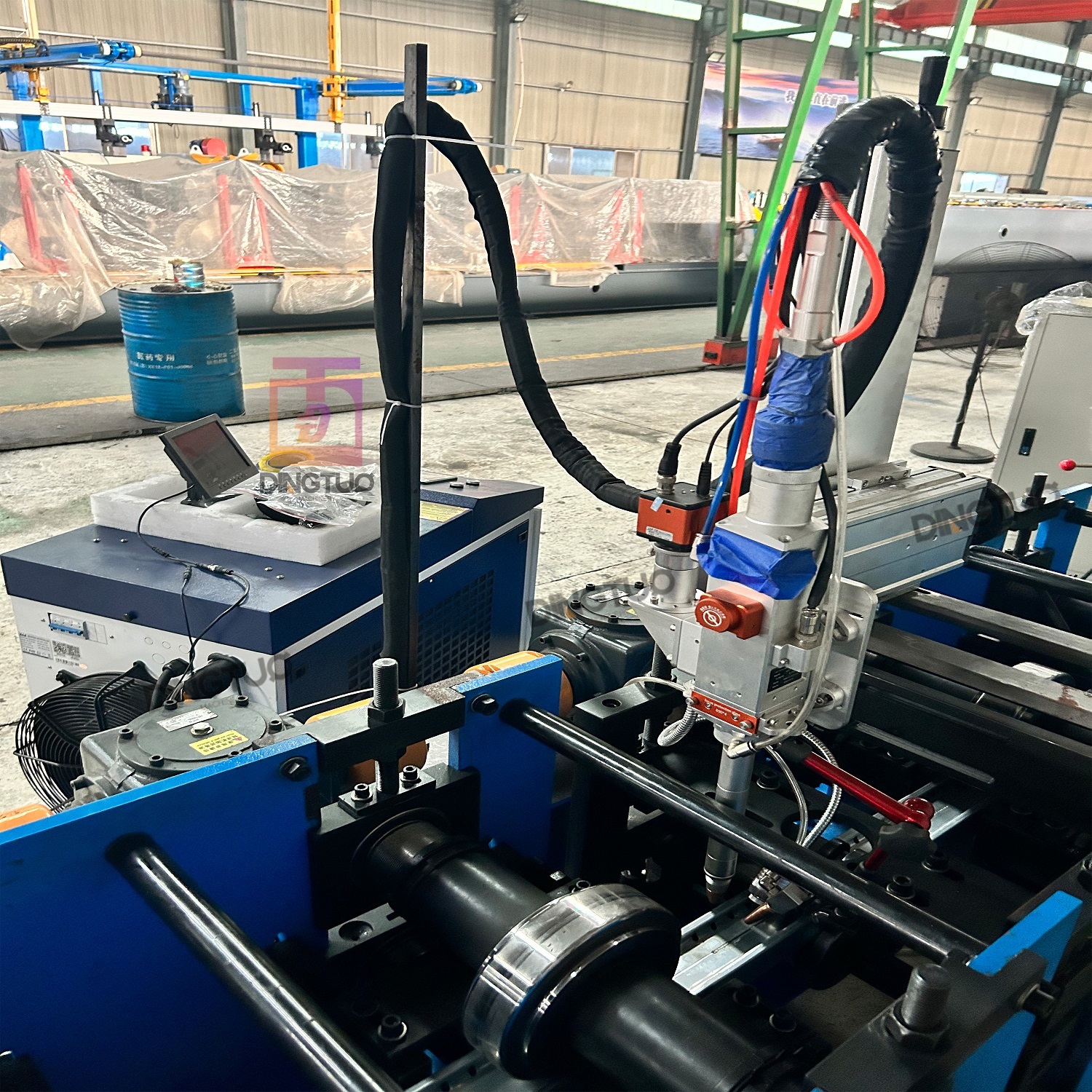

6 | WELDING UNIT | 1 |

7 | STRAIGHTENING UNIT | 1 |

8 | SERVO TRACKING FLYING SAW CUTTING UNIT | 1 |

9 | RUN OUT TABLE | 1 |

10 | SPARE PARTS | 1 |

Metal Fence Post Roll Forming Machine Parameter

No | Item | Parameter |

1 | Raw material | st37 steel and 1.2mm thickness |

2 | Feeding width | as your profile drawing |

3 | Machine stands | 20 mm plates welded or make machine stands as your needed |

4 | Machine whole line real Speed | 3m/min including whole line speed Note: Without calculating the flanging speed, the equipment can reach 8-10 meters per minute including shearing and punching |

5 | Forming station | 25 stations |

6 | Machine Total Power | 2*7.5 KW (2 main motors ) + 2.2 kw ( servo motor flying cut motor EURA Brand ) + 4kw saw cutting motor |

7 | Voltage | 380V 50HZ 3 phases or customized |

8 | Diameter of solid shaft | 60mm solid shafts |

9 | Forming Shaft | 45# steel material with tempering, fine grinding |

10 | Forming Roller | Gcr15 bearing material with turning+quenching(hardness 58-62degrees)+grinding+fine turning treatment WUXI processing |

11 | Rolling riveting unit | Fast speed ( riveting shape : square shape or rectangular shape ) |

12 | Flange punching unit | Have |

13 | Transmission | Gearboxes transmission |

14 | Touch screen/PLC | DELTA Brand ( FROM TAIWAN , CHINA ) |

15 | Low voltage electric system brand | Schneider brand ( FROM FRENCH ) |

4.1. PRODUCTION LINE MACHINE PARTS INTRODUCTION

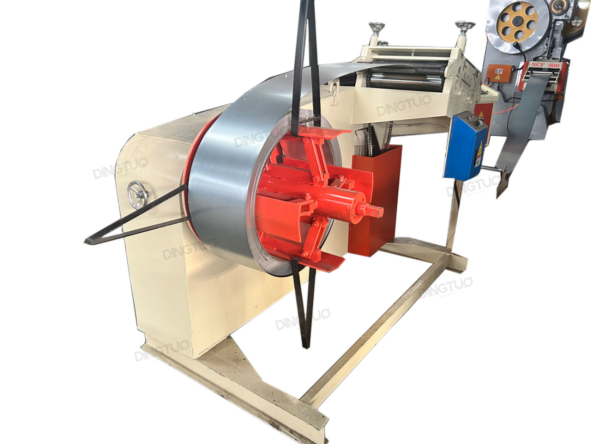

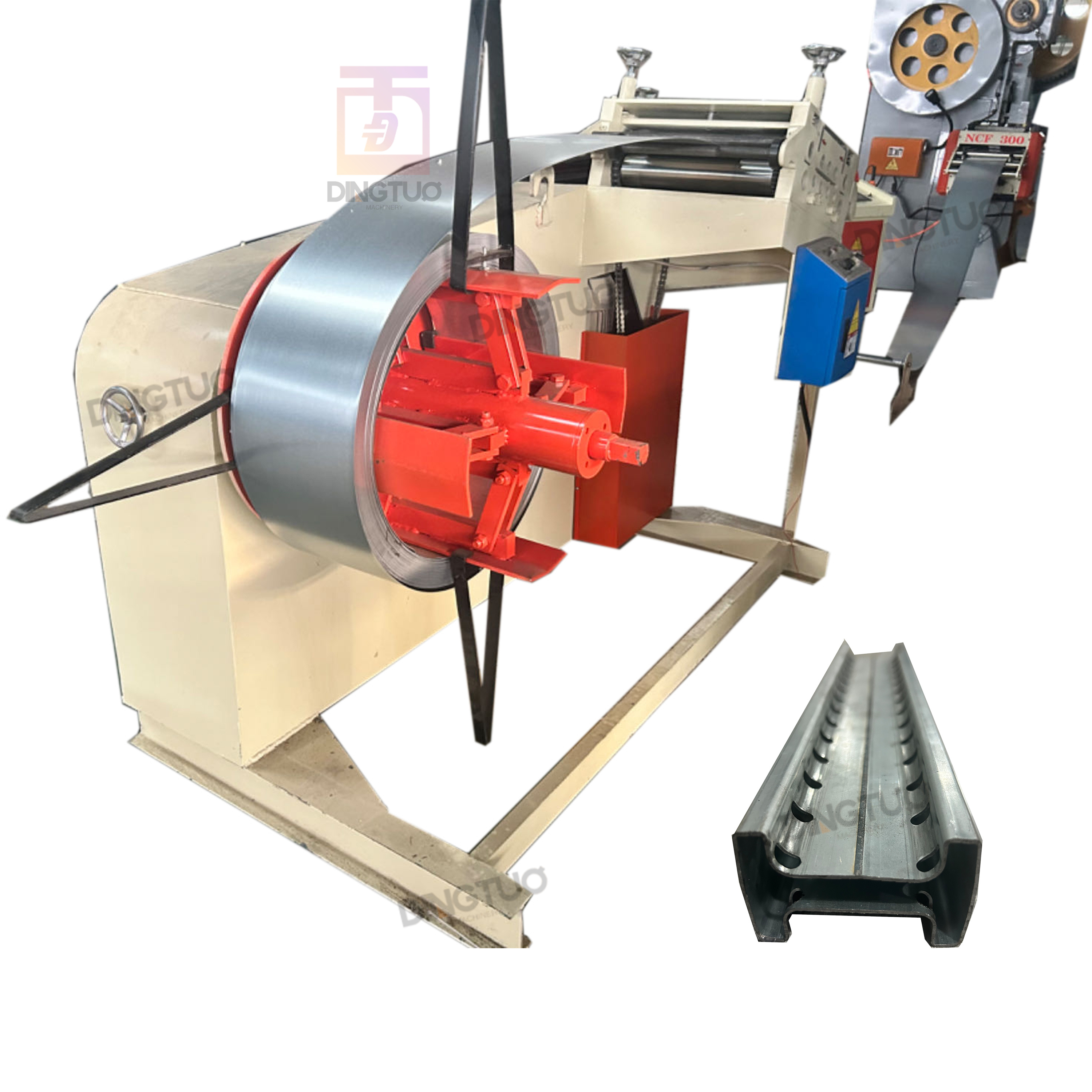

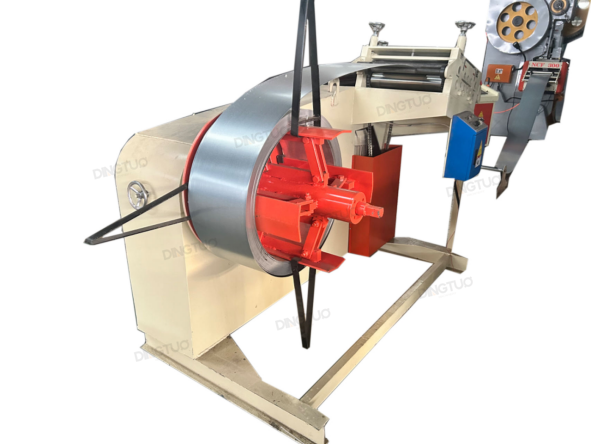

4.1.1: 2 IN 1 DECOILER AND LEVELING MACHINE

1 | TYPE | GO-400 |

2 | MATERIAL WIDTH (mm) | Within 400 |

3 | MATERIAL THICHKNESS(mm) | 0.35-2.2 |

4 | Material I.D. Ø(mm) | 450-530 |

5 | Material O.D. Ø (mm) | 1200 |

6 | Material Weight (kgs) | 1500 |

7 | SPEED OF FEED | 15M/MIN |

8 | MOTOT(HP) | 2 |

9 | Coil Expansion | MANUAL |

10 | MACHINE WEIGHT(KG) | 680 |

11 | MATHINE L×W×H(M) | 2.1×1.5×1.5 |

4.1.2: PUNCHING MACHINE AND SERVO FEERDER AND PUNCHING MOLD

40 TONS PUNCHING MACHINE PARAMETERS | |||

NO. | ITEM | UNIT | DESCRIPTION |

1 | Nominal pressure | ton | 40 |

2 | Nominal pressure stroke | mm | 6 |

3 | Slider stroke | mm | 100 |

4 | Slide stroke times | (times/min) | 55 |

5 | Maximum closing height | mm | 320 |

6 | Closed height adjustment | mm | 80 |

7 | Distance from the center line of the slider to the bed | mm | 230 |

8 | working desk size (Front and back/ left and right) | mm | 400/650 |

9 | working desk size blanking hole size (Front and back/ left and right/diameter) | mm | 170/240/160 |

10 | Overall dimensions of the bottom surface of the slider (front and rear/left and right) | mm | 220/300 |

11 | Die handle hole size(diameter/depth) | mm | 50/70 |

12 | The distance between the two columns of the fuselage | mm | 260 |

13 | Net distance between worktable and track | mm | 340 |

14 | Backing board thickness | mm | 80 |

15 | The tilt angle of the fuselage | degree | 25 |

16 | motor | kw | 4 |

Rpm | 1440 | ||

17 | Punching machine size | front and rear(mm) | 1500 |

left and right(mm) | 1100 | ||

Height(mm) | 2400 | ||

SERVO FEEDER PARAMETER | |||

18 | NCF 400 | SET | 1 SET |

PUNCHING MOLD | |||

19 | ONE SET | SET | 1 SET |

4.1.3: Machine feeding platform & rollers & shafts & machine stands & machine transmission

4.1.4 Straightening Unit And laser Welding Unit And Hydraulic Flying Saw Cut

4.1.5 : Run -Out Table : 2*3m long welded

Spare Part

No. | Name | Quantity | Country |

1 | Rely | 2pcs | China |

2 | Encoder | 2pcs | China |

3 | Encoder wheels | 2pcs | China |

4 | bearings | 2pcs | China |

5 | limit switch | 2pcs | China |

6 | Switch buttons | 3pcs | China |

7 | sensor | 4pcs | China |

8 | Oil tubes | 2pcs | China |

9 | Gears | 2pcs | China |

11 | circlip | 30pcs | China |

12 | Tool Box | 1 Set | China |

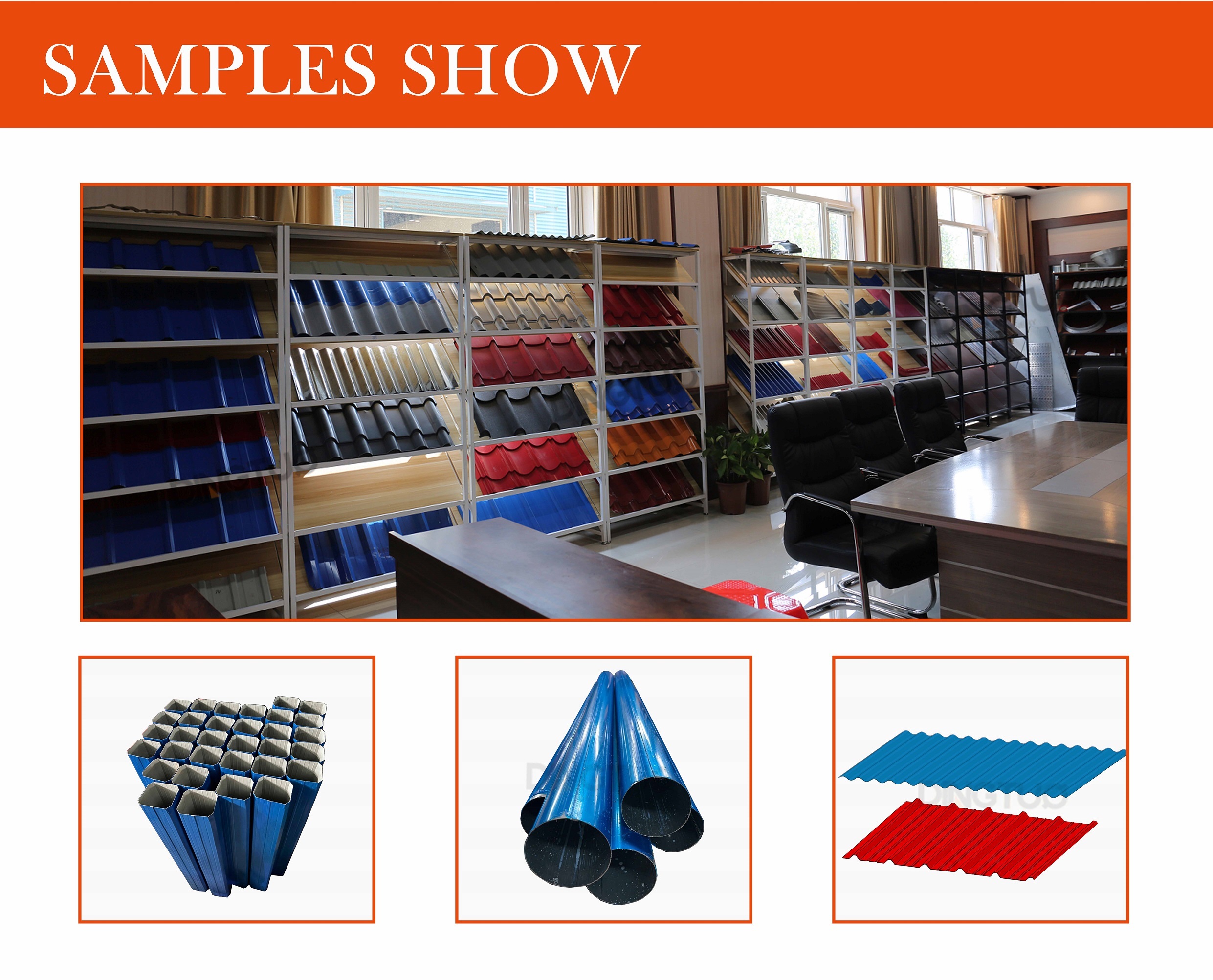

Recommend Products

Product Consulting

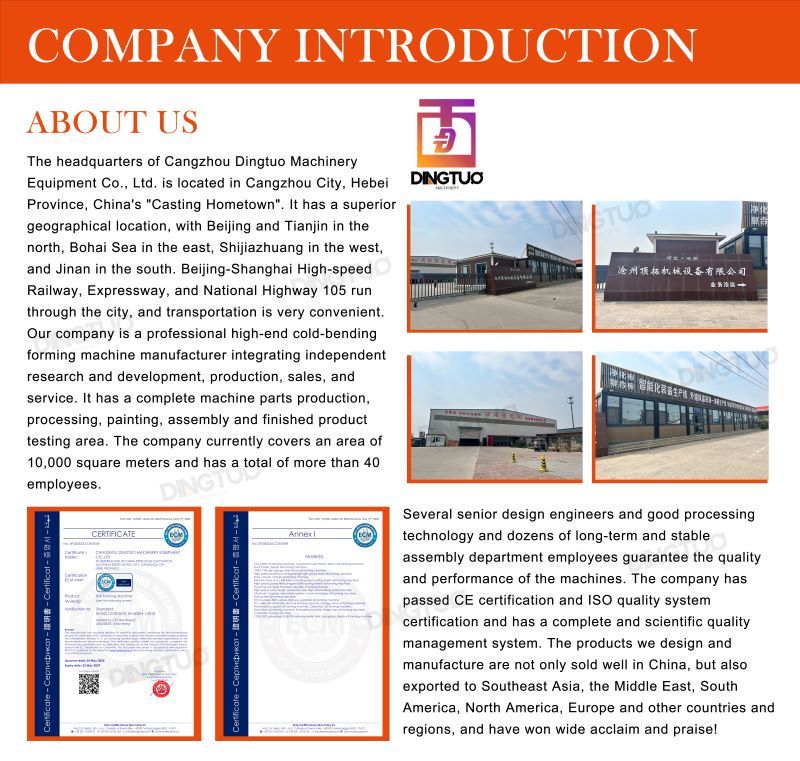

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat