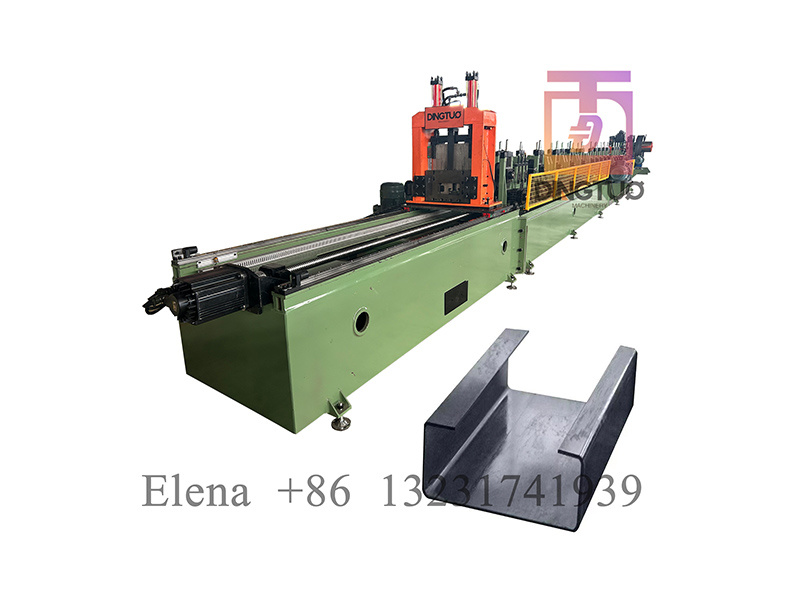

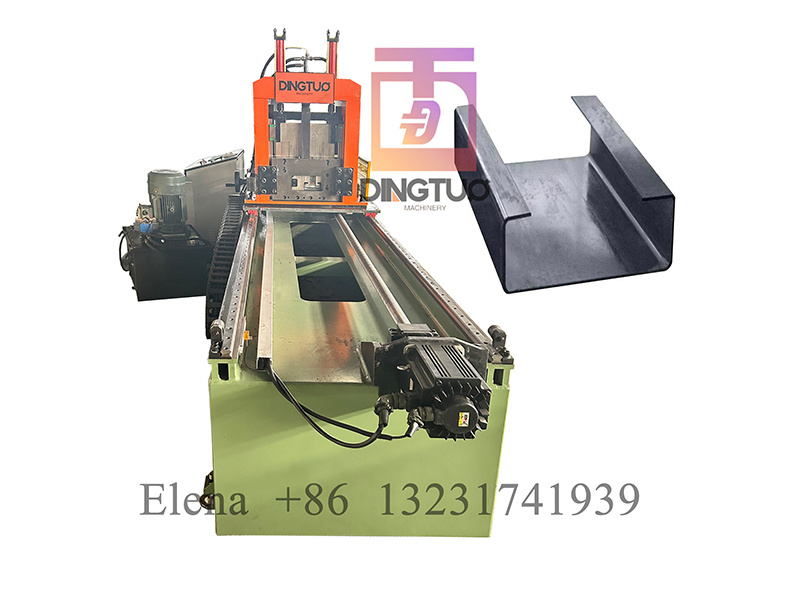

faster speed flying cut 80 to 200 c purlin roll forming machine with double head hydraulic decoiler

Key words:

Product category:

Tel/Whatsapp:

faster speed flying cut 80 to 200 c purlin roll forming machine with double head hydraulic decoiler

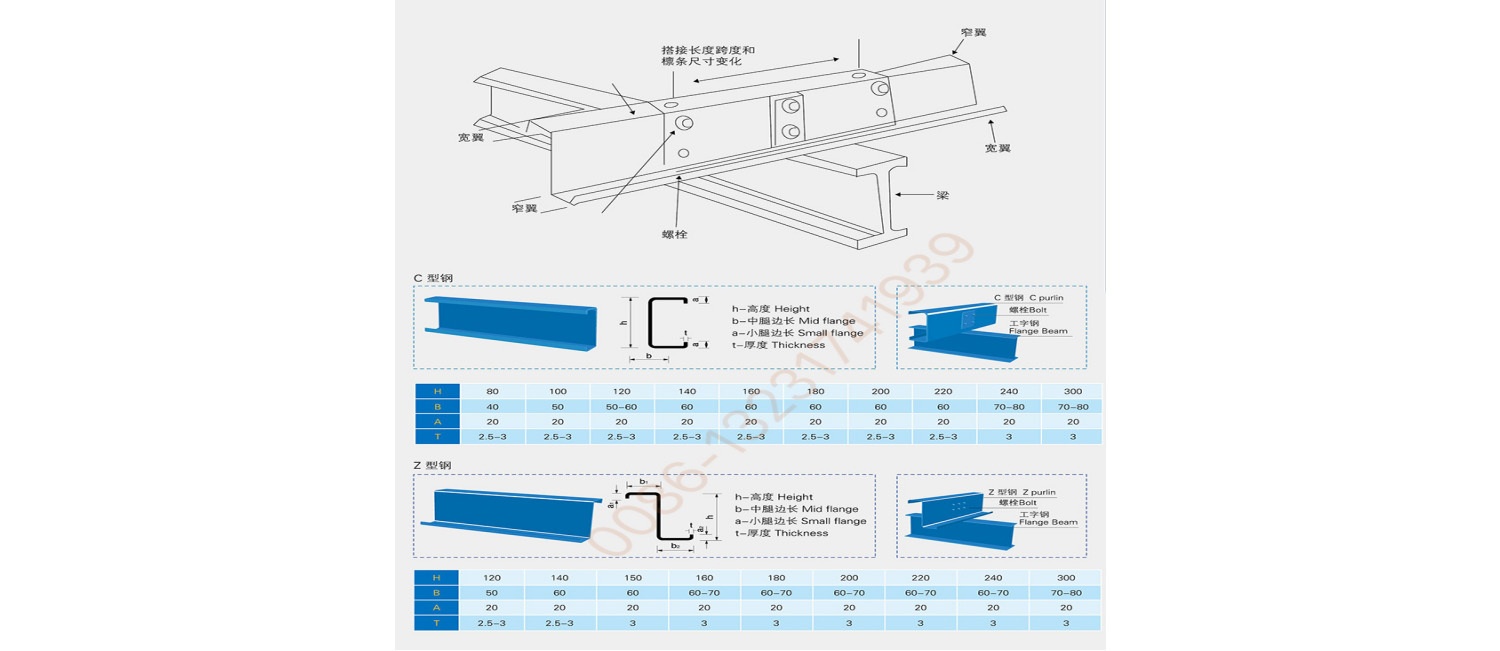

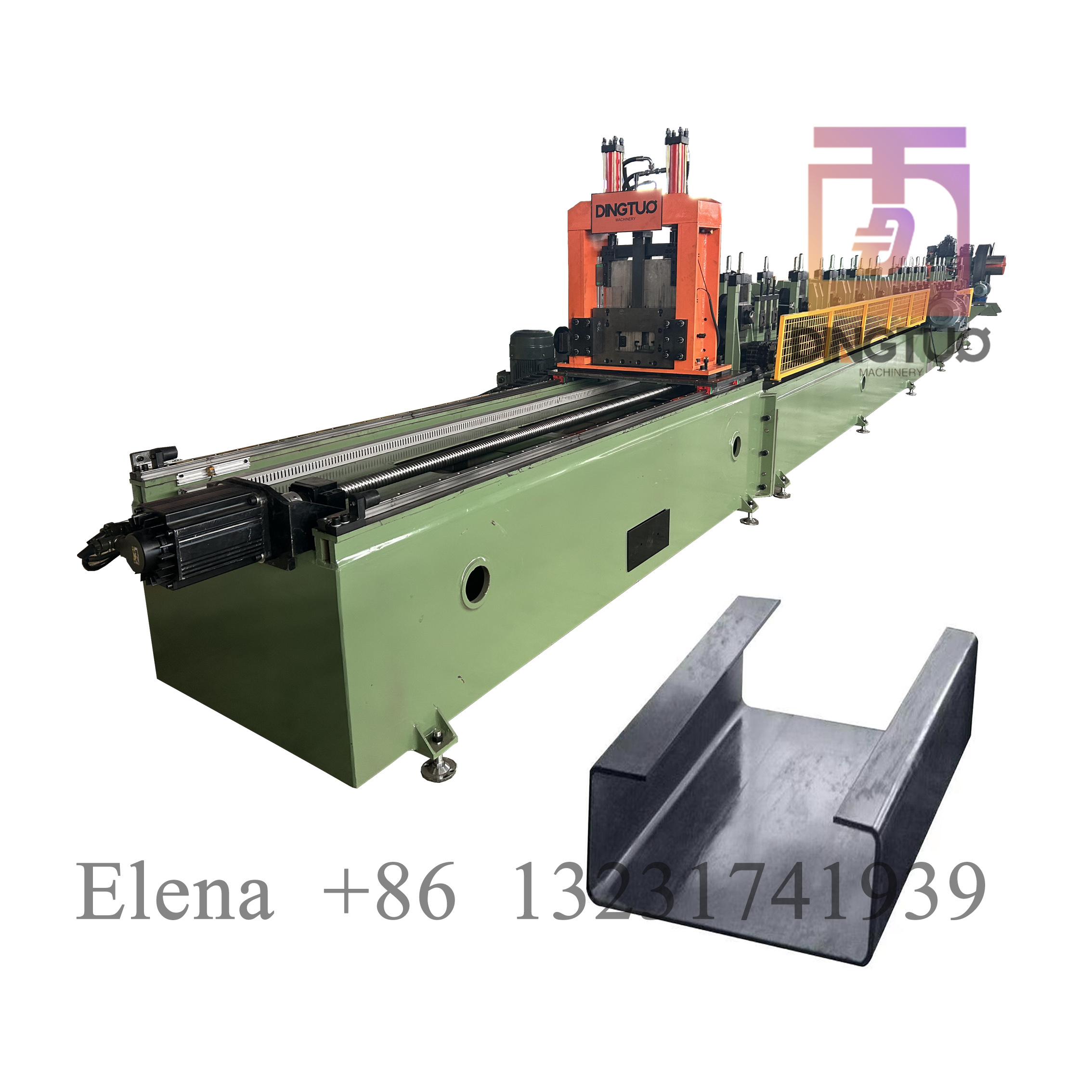

Profile Drawing

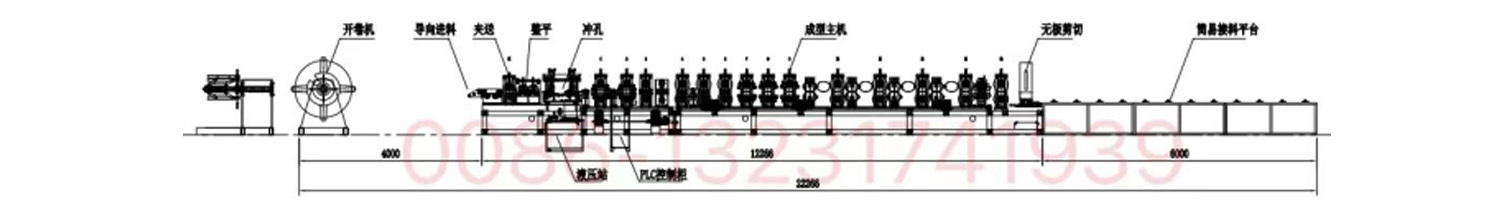

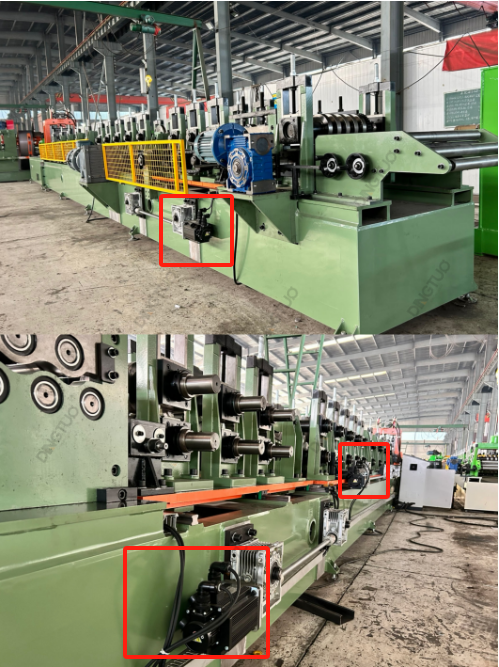

Machine Schematic Diagram

Machine Parameters

| No | Item | Parameter | Parameters’ Explanation |

| 1 | Raw material | Galvanized steel ; Carbon steel; black belt Maximum 345Mpa |

customized |

| 2 | Thickness | 1-3mm | customized |

| 3 | Decoiler | 5 tons double head hydraulic decoiler | two heads total10 tons |

| 4 | Feeding width/coil width | according to your profile drawing | according to your profile drawing |

| 5 | purlin sizes |

80-150 mm width 40-80mm height 10-15 lips |

customized |

| 6 | Machine stands | Cast iron type : 140# | More stability |

| 7 | Forming Speed | 20 m/min | Exported standard .If you need more higher speed, please let me know. The machine can realize higher speed through changing some machine design. |

| 8 | Forming station | 14 stations | Calculated the forming stations according to your profile drawing . Either no more stations to waste your purchase cost or no less stations to affect your finished profiles’ effects. The forming stations i wrote here was most suitable. |

| 9 | Total Power | 18.5kw (main servo motors power) + 11 KW(hydraulic pump station motor power) | 29.5kw.h Enough power to run the machine stably. |

| 10 | Mill bed material | table top is 30mm, the thickness of the side plate is 10mm, the whole is sanded and derusted after welding, and the table top is processed by CNC gantry milling |

Best machine base frame which is very stability |

| 11 | Voltage | 380 V ,50 HZ,3 phases | machine motor power is customized according to your voltage. |

| 12 | Diameter of shaft | 80 mm diameter solid shafts | 3mm thick material asked us to use 80 mm solid shafts for your machine. |

| 13 | Transmission type | 2 inch Chains |

Standard type can choose gear boxes transmission |

| 14 | Cutting type | Automatic Hydraulic Cutting type without changing blades when doing CZU various types | CZU uses one set of blade |

| 15 | Forming Shaft | 40Cr, quenched and tempered by heat treatment, spacer 8mm thick | Exported standard |

| 16 | Forming Roller | Gcr15 Bearing Steels with Quenching | High Grade Materials , with quenching can increase the whole materials’ hardness and abrasion resistance |

| 17 | Cutting Blade |

Cr12 with hard treatment flying cut |

Exported standard which shear life exceeds 1 million times |

| 17 | PLC/Touch Screen | DELTA brands | From Taiwan,China |

| 18 | Electrical motor | SHANGHAI BOJIANG brand | Top brand , quality tested |

| 19 | Encoder | OMRON Brand with aluminum bracket | From JAPAN |

| 20 | Low-voltage electrical | SCHNEIDER Brands | From FRANCE |

| 21 | Machine rough size | L 15m*W2.3*H2.3m | |

| 22 | Machine rough weight | 15000KGS | |

| 23 | Run out table | 6m | 2*3m |

One Set Of Double-head Decoiler (2 heads total 10 tons coil bearing weight)

Feeding&clamping& leveling part

Forming Unit

Servo Motor Size Changeable

3 Sets Of Size Changeable Motors : 2 sets of C purlin height size changeable motors ;1 set of C purlin bottom width size changeable motor

Flying Cut Infinite Shear

Run Out Table :standard/pneumatic/auto-stacker optional choice

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat