EPS semi-automatic/auto garage door panel production line used for Canada

Key words:

Product category:

Tel/Whatsapp:

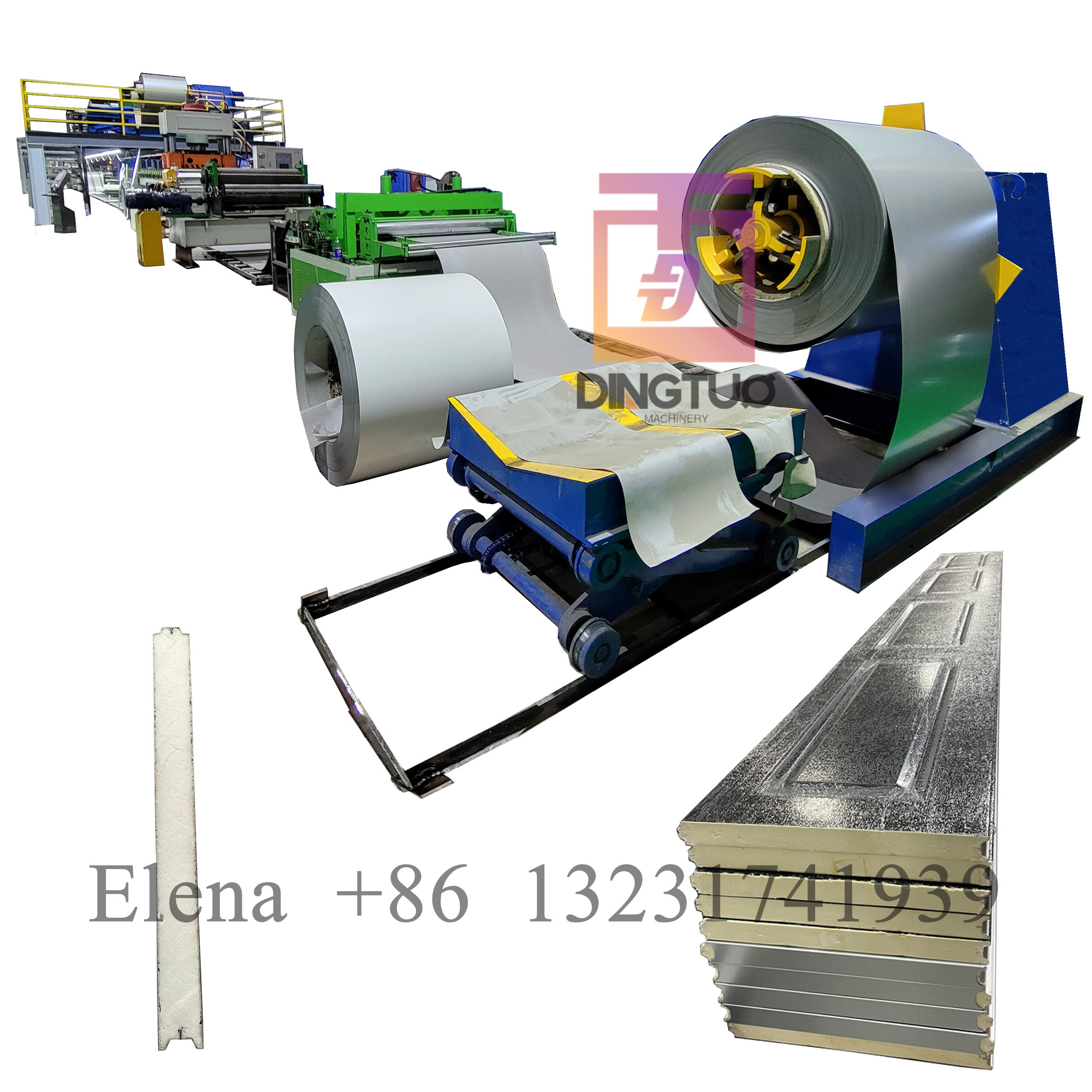

EPS semi-automatic/auto garage door panel production line used for Canada

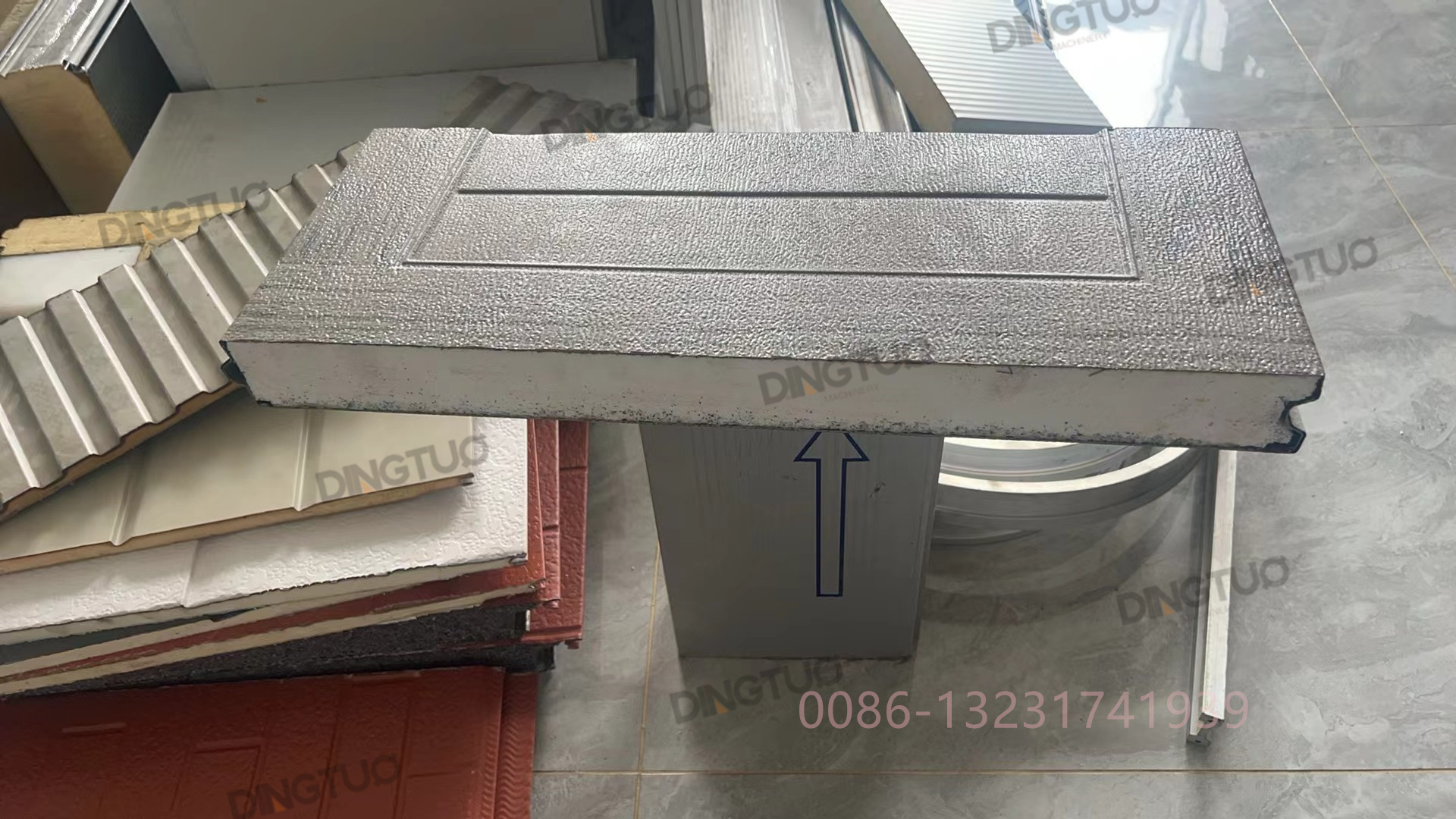

Semi-Automatic EPS Foamed Garage Door Production Line

EPS Foamed Garage Door Production Line is successfully tested running in our workshop. EPS Foamed garage door prodcution line is designed to produce industrial garage doors. This PU/EPS foamed garage door production line is a continuous EPS sandwich panel line that produces double-skinned sectional door panels with polyurethane insulated core. This garage door production line mainly consists of uncoiler, leveler, upper and lower roll formers, EPS foam injection machine, hydraulic press, fly saw cutting system. Nowdays, garage door is widely applied in private garages and public parking lots. The most advantage of this garage door are as below: 1. fast rolling 2. widen shutter slats, much safety 3. less space required, and is suitable for lower floor area.

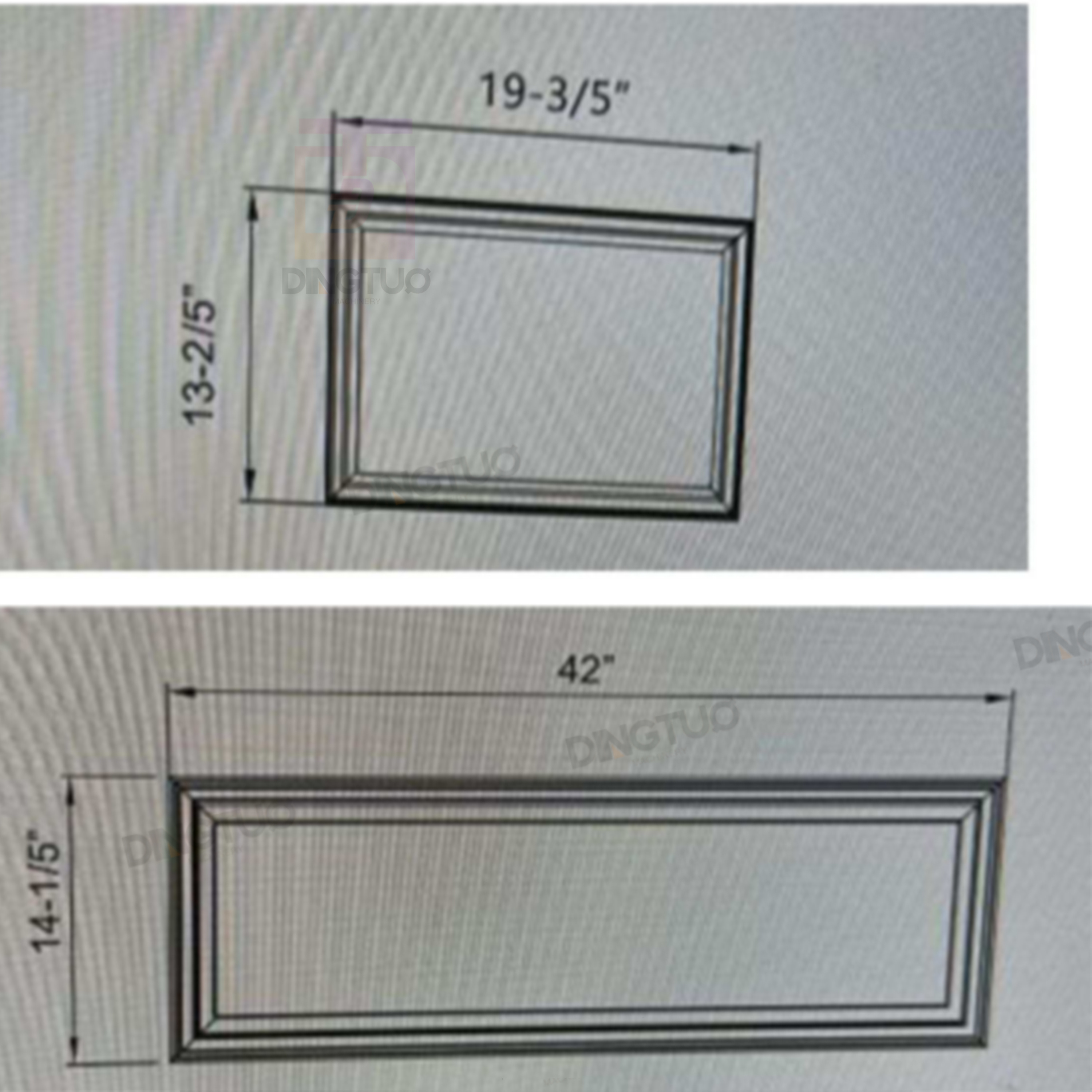

Profile Drawing: (customized)

Production Line General Parameter :

- PRODUCTION LINE SPACE TOTAL : L35M*W10M ENOUGH

- PRODUCTION LINE POWER TOTAL : ABOUT 160KW

- PRODUCTION LINE PRODUCTIVITY :6M SHEET , 12PCS/H

Production Line Components :

|

NO. |

Description |

Quantity (set) |

|

1 |

5T hydraulic decoiler with coil car |

1 |

|

2 |

Embossing roller 800mm feed |

1 |

|

3 |

Feeding and leveling machine |

1 |

|

4 |

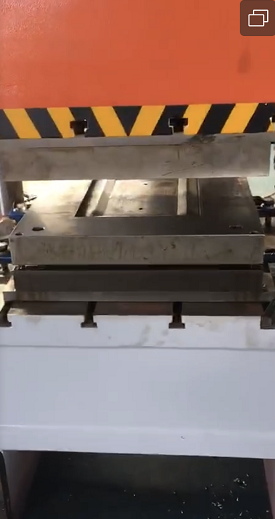

315 tons YANGLI BRAND hydraulic oil pressing machine |

1 |

|

5 |

Pattern dies ( one big and one small ) |

2 |

|

6 |

High Quality Hydraulic Cutting Machine |

1 |

|

7 |

6m Electric conveyor platform |

1 |

|

8 |

Roll forming machine |

1 |

|

9 |

6 meters Run out table |

1 |

|

10 |

High pressure foaming machine |

1 |

|

11 |

6 meters foaming table |

2 |

|

12 |

Hydraulic pump station and electric control cabinet |

1 |

1. Decoiler

2. EMBOSSING ROLLER

3. SERVO FEEDER AND LEVELING MACHINE

4.YANGLI BRAND HYDRAULIC OIL PRESSING MACHINE

5. PATTERN DIES * 2SETS

6. HYDRAULIC CUTTER

7. ELECTRIC CONVEYOR PLATFORM TO ENTER INTO ROLL FORMING MACHINE

8.ROLL FORMING MACHINE

a. Purpose: The cold bending forming machine is used to cold bend and deform the sheet into the required profile.

b. Function and structure: The sheet is rolled through a 20-piece forming mold and gradually becomes the base plate required by the drawing.

c. The rollers are forged with GCr15 and CNC machined after overall quenching. The hardness can reach HRC56-62°.

Processing technology: rough machining, heat treatment, finishing.

d. Host frame: overall welding, CNC processing.

e. Forming frame: column arch type, chain drive.

f. The archway is a casting and the slider is a casting. It is cast, annealed and CNC finished.

g.Chain drive. The transmission is smooth and the molding precision is high.

h. Roller shaft diameter: ¢60mm Material: 45# steel

Processing technology: quenching and tempering, rough machining, finishing

i. Bearing brand: Harbin Bearing

j. Main drive motor: 7.5kw

9.6M FOAMING TABLE *2

4.9.2. HIGH PRESSURE FOAMING MACHINE

Foaming machine configuration sheet:

|

Item |

Parameters |

Quantities |

|

1、 base frame |

1800mm*1420mm*2300mm |

1set |

|

2、 Original solution barrel |

Volume 250 liters (including stirring motor) |

2sets |

|

3-1、Metering system motor |

1.5KW reduction motor, speed ratio 10 |

2sets |

|

3-2. Metering system connector |

Pump frame + coupling |

2sets |

|

3-3. Metering system metering pump |

CW-9CC/CW-12CC gear pump |

2sets |

|

4. Filtration system |

Diameter 100 filter + filter |

2pieces |

|

5. Equipment pouring head |

High pressure nozzle type |

1set |

|

6-1. Equipment electrical cabinet |

Factory standard distribution cabinet 1.5m*700*280mm |

1set |

|

6-2. Electrical appliances |

Circuit board assembly Chint Electric |

1set |

|

6-3. Frequency converter |

Delta 2.2KW inverter |

2sets |

|

6-4. Control system |

Delta PLC + Delta touch screen |

1套 |

|

6-5. Control collection feedback |

Delta input module + 4-20mA pressure transmitter 3 pieces |

1set |

|

7-1. Hydraulic station |

Volume 88L |

1set |

|

7-2. Hydraulic station motor |

3kW/Level 4//5MCY14-1B |

1set |

|

7-3. Hydraulic station energy storage device |

NXQ-4.0/31.5-L-Y |

1set |

|

10. Automatic feeding of equipment |

2.2/1.5KW motor + KCB55 gear pump |

2sets |

Foaming equipment technical parameters:

1. Suitable foam types: soft foam, semi-hard foam, hard foam, self-crusting

2. Suitable viscosity: (normal temperature 22 degrees Celsius)

Polyether polyol: -2000MPa.s Polyisocyanate: -1000MPa.s

3. Material to weight ratio: 1:1

4. After mixing A and B, the injection amount is 15g-100g/sec.

5. Injection time: continuous or intermittent injection (1.00-99.99 accurate to 0.01s)

6. Original liquid barrel: The volume of the original liquid barrel is 250 liters/piece, and 2 pieces are required. The inner tank of the raw liquid barrel is made of 304 stainless steel * 3mm thick. The outer tank is made of cold plate 5mm thick and sheet metal welded. The raw liquid barrel is equipped with: raw liquid stirring reducer, raw material constant temperature heating tube. The display is equipped with a level gauge.

|

4.9.3. ELECTRIC CONTROL CABINET

a. The whole machine adopts PLC control, LCD touch screen and human-machine interface. Realize the interaction between people and PLC. The operator automatically operates through the set program (programmable control) and monitors the control process, allowing the operator to control the production line and modify the control parameters, and can monitor the equipment operating status, operating parameters and fault indications in real time. The length of the workpiece is digitally set and the length of the workpiece is adjustable. Real-time monitoring of equipment operating status and fault indications.

b. There are two modes of operation: manual/automatic. It has manual and automatic switching functions: in the manual state, it can operate as a single machine, which is convenient for maintenance; in the automatic state, it can carry out full-line production operation and start in sequence; the entire line is equipped with emergency stop buttons, which is easy to handle emergencies and ensures the safety of equipment operators. Safety.

c. There is a manual operation panel next to the machine for workers to operate.

d..Main electrical components

1)PLC: Delta

2) Frequency converter: Delta

3) Touch screen: Delta

4) Encoder: Omron

Spare Part

|

No. |

Name |

Quantity |

Country |

|

1 |

Rely |

2pcs |

China |

|

2 |

Encoder |

2pcs |

China |

|

3 |

Encoder wheels |

2pcs |

China |

|

4 |

bearings |

2pcs |

China |

|

5 |

limit switch |

2pcs |

China |

|

6 |

Switch buttons |

3pcs |

China |

|

7 |

sensor |

4pcs |

China |

|

8 |

Oil tubes |

2pcs |

China |

|

9 |

Gears |

2pcs |

China |

|

11 |

circlip |

30pcs |

China |

|

12 |

Tool Box |

1 Set |

China |

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat