Kazakhstan Türkiye Russia Commonly used garage door panel production line

Key words:

Product category:

Tel/Whatsapp:

Kazakhstan Türkiye Russia Commonly used garage door panel production line

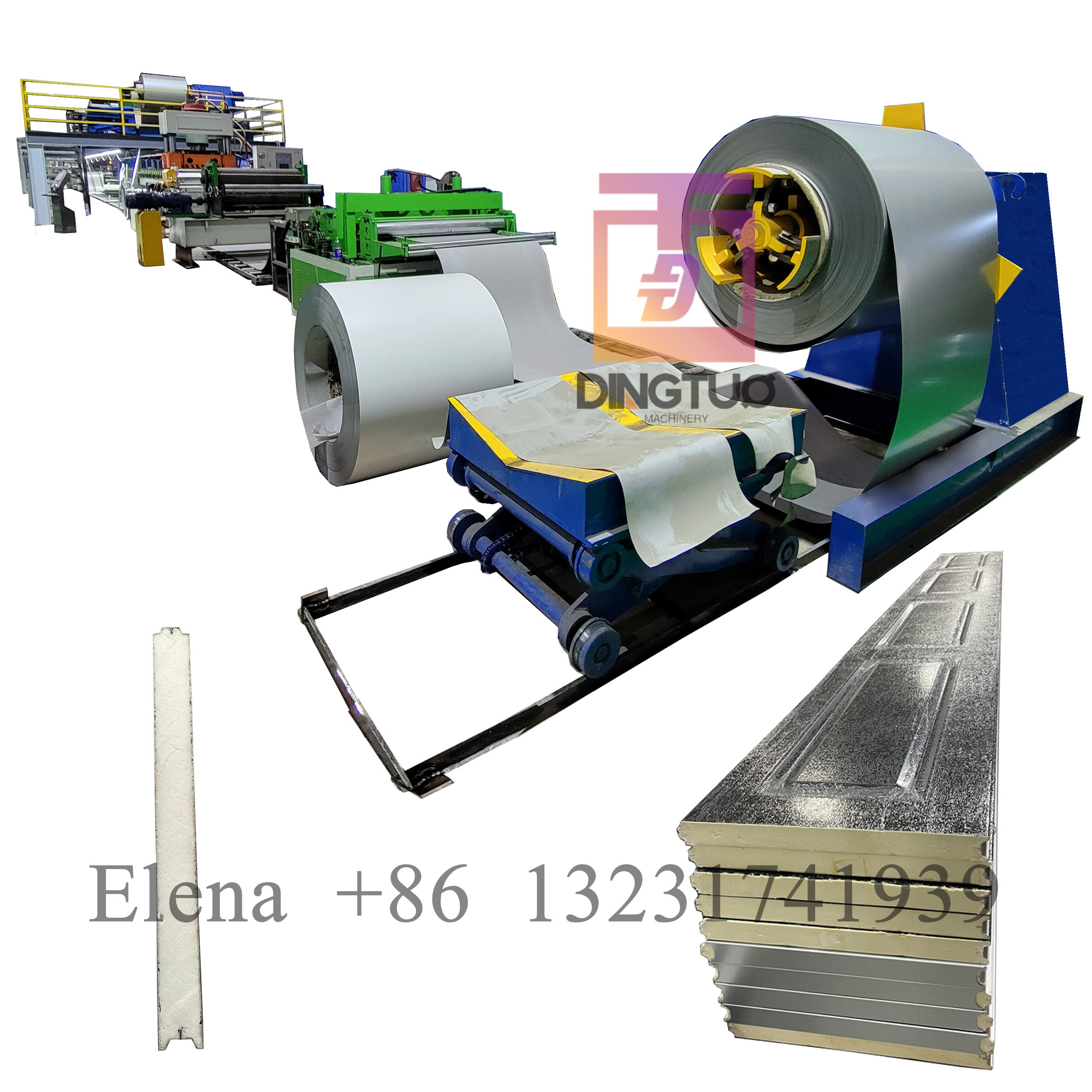

KAZAKHSTAN TURKIYE RUSSIA COMMONLY USED GARAGE DOOR PANEL PRODUCTION LINE

CANGZHOU DIGNTUO MACHINERY EQUIPMENT CO.,LTD is specially in all kind of garage door panel roll forming machines and industrial door panel machines. We can provide continuous line or discontinuous line according to customer’s requirement. Continuous line is from entry coil to finished door panels, high efficiency. Discontinuous line is separately working for door panels, and foam injection. Discontinuous line is a great alternative for the customer with limit space, lower production need.

Automatic PU Foam Roll Forming Machine Profile Drawing: (customized)

Production Line General Parameter :

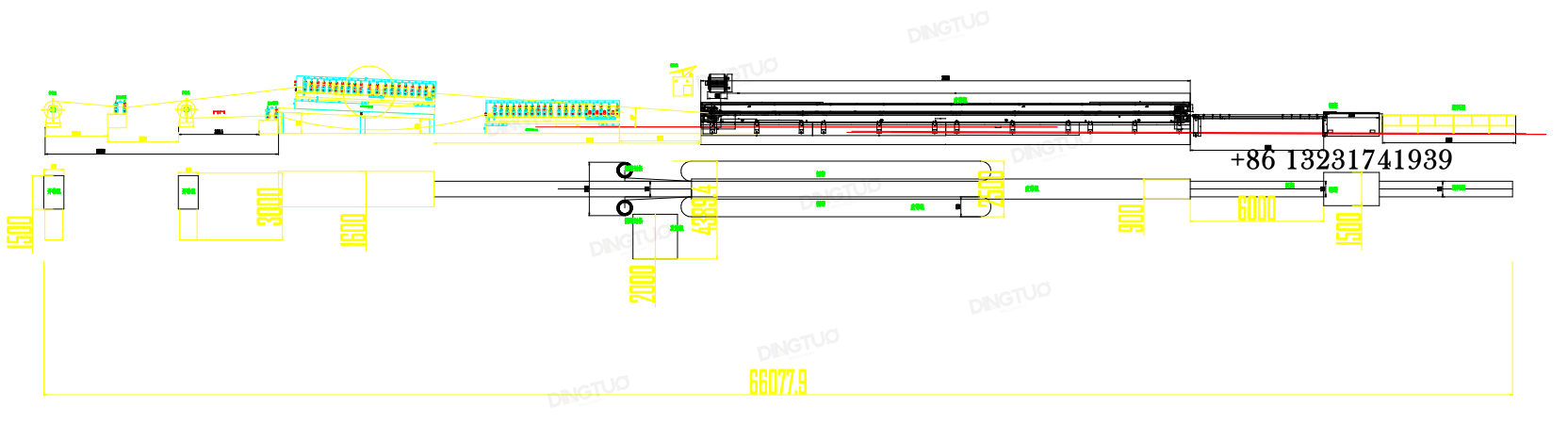

- PRODUCTION LINE SPACE TOTAL : L70M*W2M*H2M ,WEIGHT :30000KGS

- PRODUCTION LINE TOTAL POWER : 100KW

- PRODUCTION LINE PRODUCTIVITY :6M SHEET , 12PCS/H

- LOADING CONTAINER : 4 * 4HQ CONTAINERS

Machine Outlet

NO. | Description | Quantity (set) |

1. | Roll forming machine part | |

1.1 | 5T *1000mm wide manual decoiler with coil car | 2 |

1.2 | Embossing and lamination equipment | 2 |

1.3 | Roll forming machine | 2 |

1.4 | Second floor platform and viaduct and upper and lower layer machine conveyor platform | 1 |

1.5 | Electric control cabinet | 1 |

2 | Sweeping and foaming unit | |

2.1 | High pressure continuous foaming machine | 1 |

2.2 | Sweep cloth system | 1 |

2.3 | Electrical control system | 1 |

3 | Double-layer belt laminator system | |

3.1 | 24m double-layer belt laminator system | 1 |

3.2 | Side sealing chain supports and systems | 1 |

3.3 | Each specification of side rail mold | 1 |

4 | Hydraulic Cutting part | |

4.1 | Cutting machine servo tracking cutting | 1 |

4.2 | Finished product conveyor belt | 1 |

Production Line Components

1 . roll forming machine part :

- 5 tons hydraulic decoiler X 2sets

- Embossing and lamination equipment X 2sets

3. roll forming machine X 2 sets

4. platform ( pictures for reference , real platform will customized as machine budget )

standard platform size:L19m*W3m*H2m

2 . Sweeping And Foaming part :

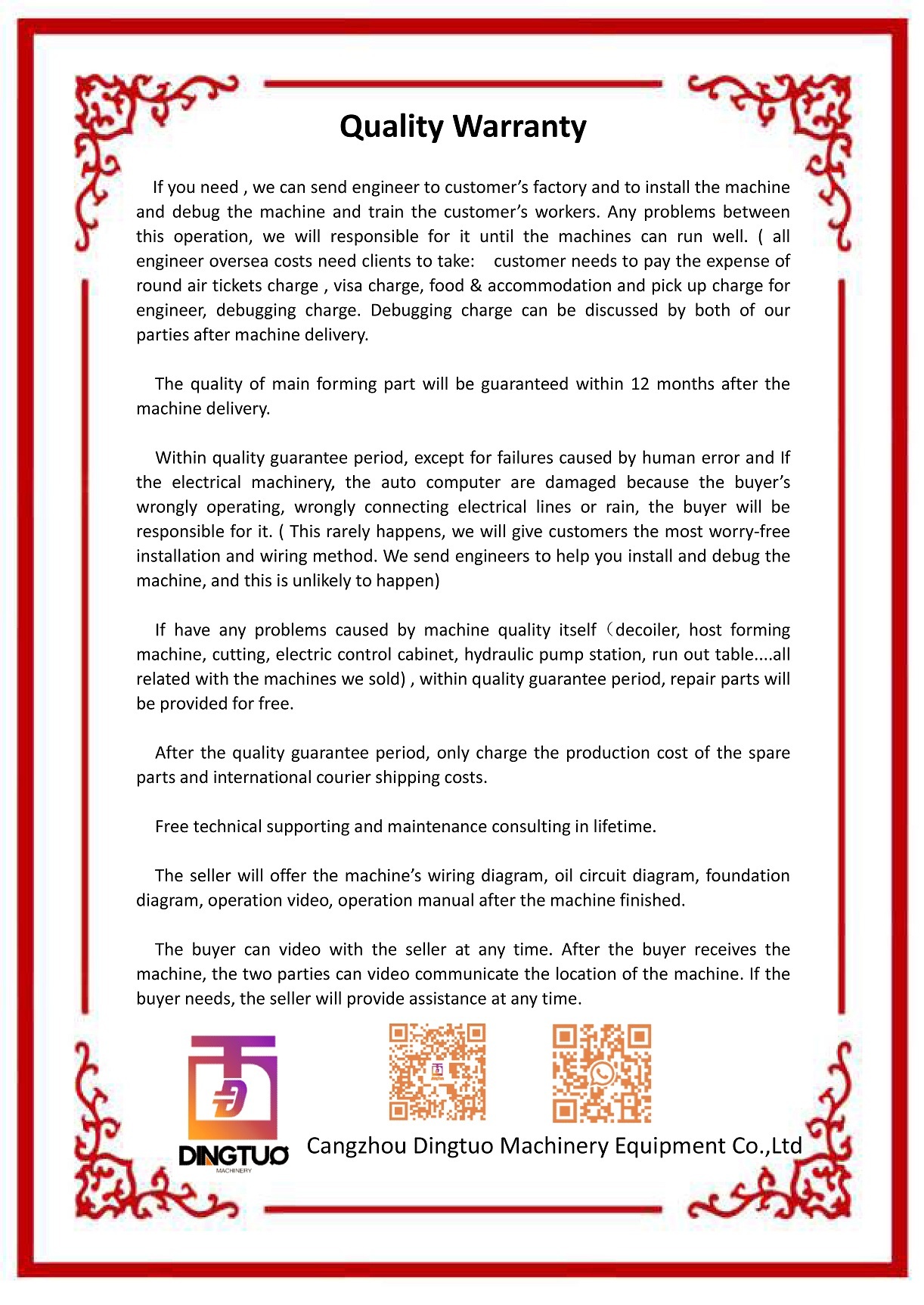

1. Suitable foam types: soft foam, semi-rigid foam, rigid foam, self-skinning

2. Suitable viscosity: (normal temperature 22 degrees Celsius)

Polyether polyol: -2000MPa.s Polyisocyanate: -1000MPa.s

3. Material weight ratio: 1:1

4. The injection amount after A and B are mixed is 15g-100g/sec

5. Injection time: continuous or intermittent injection (1.00-99.99 accurate to 0.01s)

6. Stock liquid barrel: The volume of the stock liquid barrel is 500 liters/piece, and 2 pieces are required. The inner liner of the stock liquid barrel is 304 stainless steel * 3mm thick. The outer liner is a cold plate 5mm thick and sheet metal welded. The stock liquid barrel is equipped with: stock liquid mixing reducer, raw material constant temperature heating tube. The display is equipped with a liquid level gauge.

3 . DOUBLE-LAYER BELT LAMINATOR UNIT :

The polyurethane mixture applied to the lower layer is conveyed to the laminator for curing synchronously with the upper layer.

The double belt laminator is designed to control the pressure rising during the foam reaction. The unit consists of an upper and lower belt. The side sealing chains on both sides are the closed foam and also contain the pressure of the side sealing foam. When the chain bolts move into the teeth of the sprocket, the return wheel prevents the pitching effect of the slats. This measure prevents any distortion and scratching of the panel surface.

In addition, high-precision manufacturing methods such as gap tolerance, vertical offset between slats and parallelism between upper and lower belts are required to achieve the requirements of panel surface appearance.

The double crawler machine is driven by two motors, one for the upper and lower. The motor of the lower belt acts as the pilot drive of the laminator and is electronically synchronized with the motor of the upper crawler to achieve completely uniform and parallel movement of the two belts.

There is superior heat transfer and heat distribution to better control the temperature of the foaming amount.

Main technical parameters:

Double crawler: length: 22 meters

Belt width: maximum width 0.7 meters

Number of lifting gearboxes: 24 sets

Lifting shaft diameter: ¢60mm

Lifting motor: 1.5KW*1 set

Chain plate lifting stroke: maximum 200 mm

Chain belt lifting time: about 2 minutes

4 . CUTTING UNIT

Spare Part

No. | Name | Quantity | Country |

1 | Rely | 2pcs | China |

2 | Encoder | 2pcs | China |

3 | Encoder wheels | 2pcs | China |

4 | bearings | 2pcs | China |

5 | limit switch | 2pcs | China |

6 | Switch buttons | 3pcs | China |

7 | sensor | 4pcs | China |

8 | Oil tubes | 2pcs | China |

9 | Gears | 2pcs | China |

11 | circlip | 30pcs | China |

12 | Tool Box | 1 Set | China |

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat