perforated 45 55 77 95 cassette quick change all in one type PU foam rolling shutter slat roll forming machine

Key words:

Product category:

Tel/Whatsapp:

perforated 45 55 77 95 cassette quick change all in one type PU foam rolling shutter slat roll forming machine

Automatic 45 55 77 95 all in 1 Cassette Quick Change Type PU Foamed Rolling Shutter Slat Roll Forming Machine

This is a high-speed production line for perforated 77 PU foam rolling shutter slats. The entire process, from the coil to the finished PU shutter slats, is fully automated. The Polyurethane Rolling Shutter Door/Window Production Line continuously manufactures rolling shutter door and window slats. The equipment primarily comprises a decoiler, feeding guide, roll forming unit, Insulation oven device, PU foam injection machine, shaping and curing system, servo flying saw cutting unit, automatic conveyor platform, high-speed punching device, and output table. The operational speed of the entire line ranges from 40 to 60 meters per minute, and it processes aluminum sheets with a thickness of 0.2 to 0.3 mm.

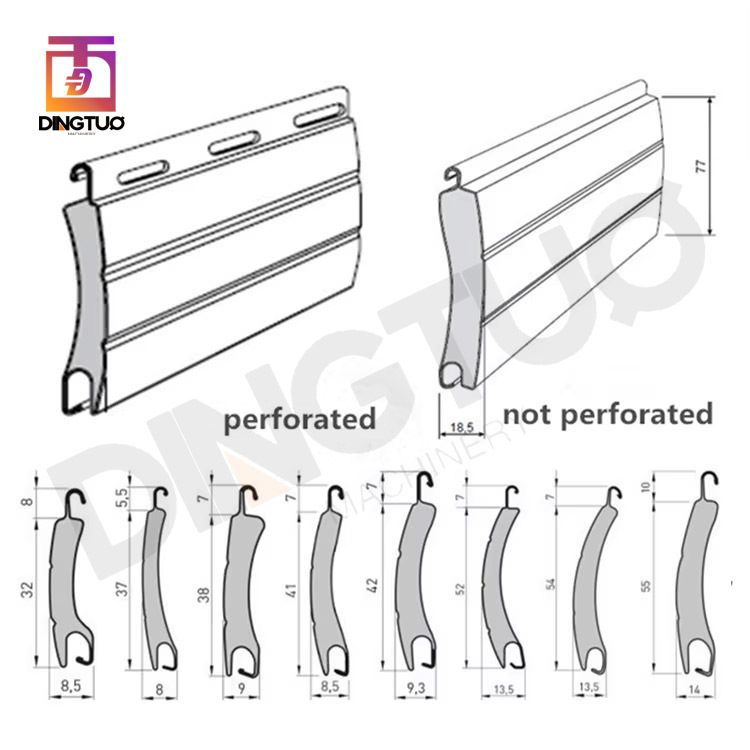

Profile Drawing: (customized)

Profile Drawing: (customized)

PU Shutter Slats' Parameter :

- raw material thickness:0.2-0.3mm

- raw material :aluminum

- whole production line speed :high speed 40-60m/min (40m/min included punching ,60m/min without punching)

- PU rolling door slat straightness error: <+-1.5mm/1500mm

- PU rolling door slat angle error: <+-1.5mm/1000mm

- PU rolling door slat fixed length error: 10m+-1.5mm

Production Line Components :

NO. | Description | Quantity (set) |

1 | 3T manual decoiler | 1 |

2 | forming unit | 1 |

3 | Insulation oven device | 1 |

4 | PU foam injection machine | 1 |

5 | shaping and curing part | 2 |

6 | servo flying saw cutting part | 1 |

7 | automatic conveyor platform | 1 |

8 | high-speed punching device | 1 |

9 | 6 meters Run out table | 1 |

10 | output table | 1 |

1. Decoiler

a. Inner diameter of the material roll: ¢500mm; Inner diameter expansion and contraction range: ¢400--¢520mm

b. Maximum outer diameter of the material roll: ¢1200 mm; Maximum load-bearing weight: 3T

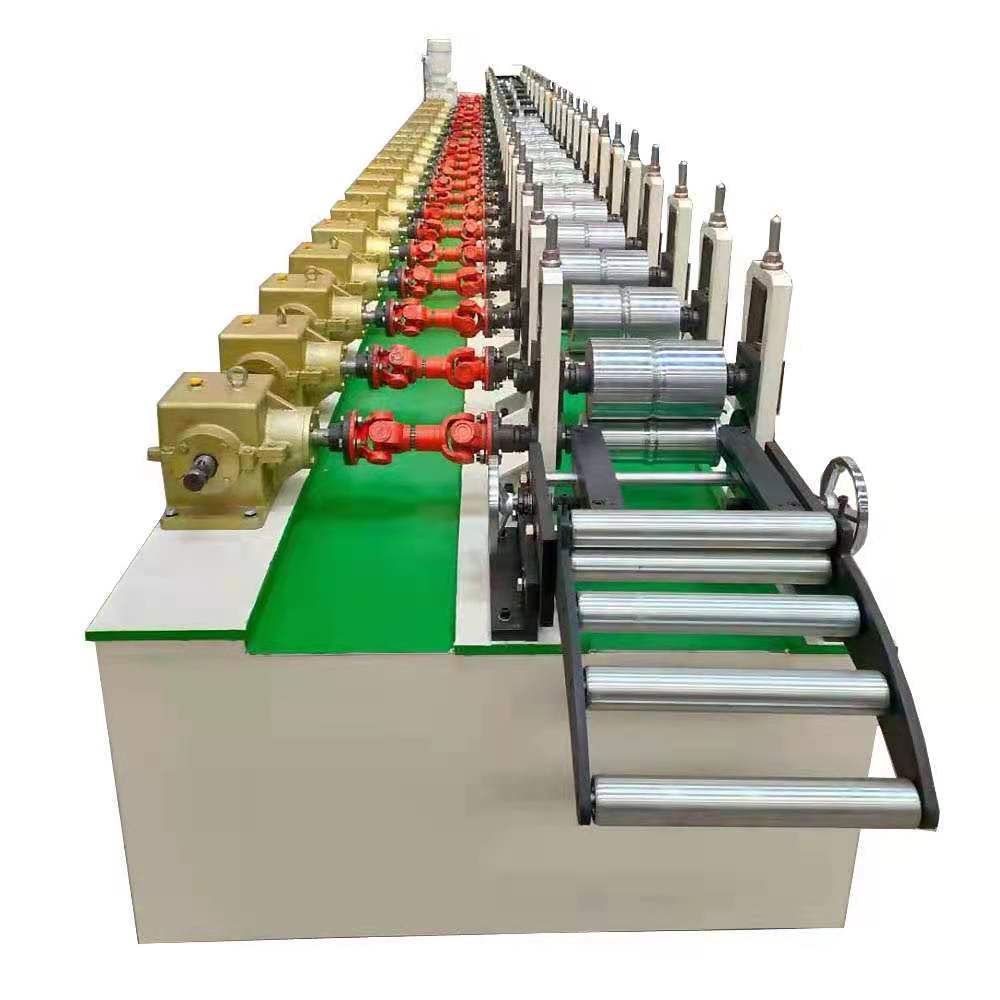

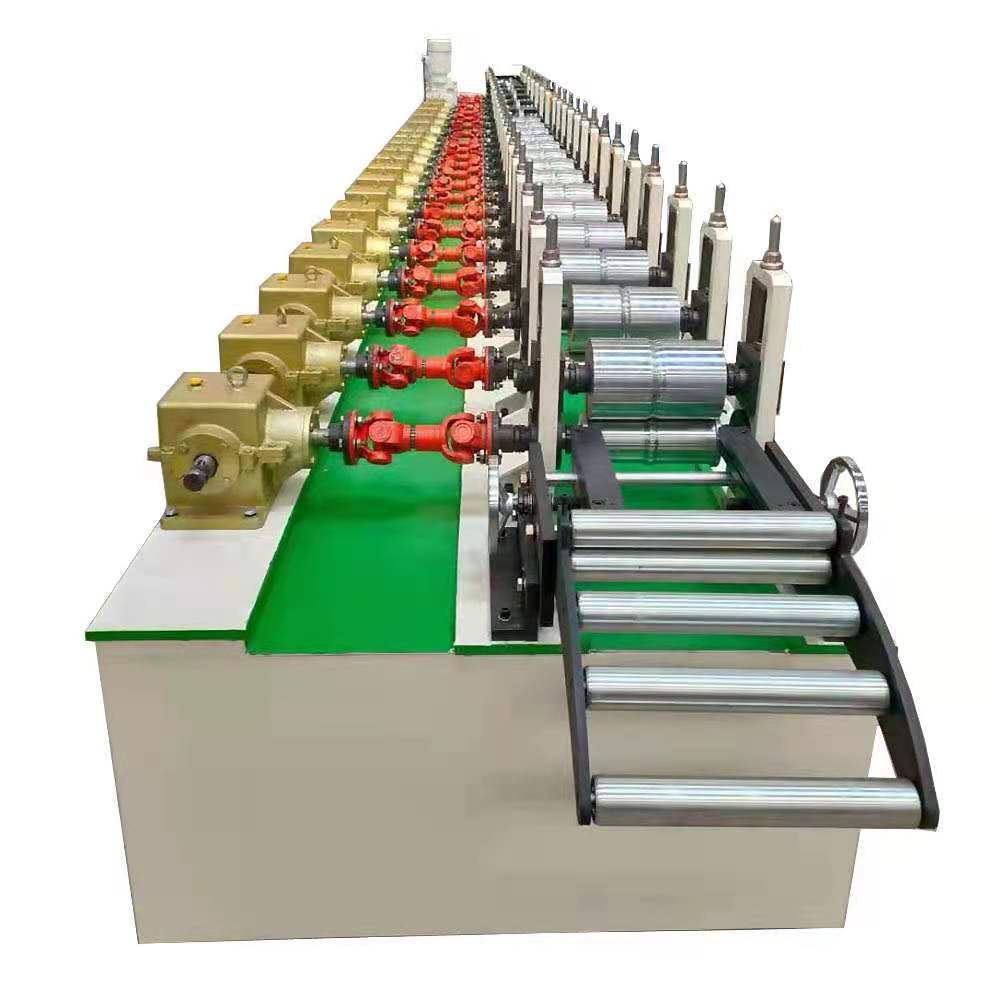

2. FORMING UNIT

a. Purpose: The cold bending forming machine is used to cold bend the sheet to the required profile.

b. Function and structure: The PU shutter slat is rolled through 37 sets of forming stations

c. The roller is made of 45# steel, which is CNC machined after overall quenching. The hardness can reach HRC55-58°. It has the advantages of high strength, high hardness, high precision and long service life.

d. Main machine frame: whole iron plates welded ,Iron Plates with CNC machined.

e. Forming passes: 37

f. Forming frame: cast iron machine stands, gearboxes transmission.

g. Roller shaft diameter: ¢40mm. Material: 45# steel.

Processing technology: quenching and tempering, rough machining, fine machining.

h. Roller die material: 45# steel.

Processing technology: rough machining, heat treatment, fine machining. Quenching hardness: HRC55-58°

i. Main drive motor: 7.5k

3. INSULATION OVEN DEVICE

Install an insulation box before and after foaming to heat the material and help foaming

4.PU FOAM INJECTION MACHINE

Reference for foam glue and the number of meters of produced profiles:

A barrel of foam glue purchased from outside is generally 250 liters, which can produce more than 10,000 meters of PU rolling door slats (the thinner the profile thickness, the more meters produced). The foam barrel that comes standard with our equipment can add 70-100 liters of foam glue at a time, and glue can be added while production is in progress without affecting normal production.

5. SHAPING AND CURING UNIT

6. LEVELING UNIT AND FLYING SAW CUTTING UNIT

a. Form: Flying saw shearing

b. Structural features: Cutting is an independent mechanism, from the bottom up. The length is set by the PLC main computer, and the cutting length can be set by yourself. Flying saw cutting process, small deformation of the cutting end face, no burrs, fast blade replacement, high production efficiency.

c. Cutting mode status: non-stop

7. AUTOMATIC CONVEYOR PLATFORM AND HIGH SPEED PUNCHING DEVICE

a. Servo feeding: 3KW

b. Hydraulic punching: 11KW

c. Automatic conveyor platform size: 8500mm*140mm*5mm

8. RUN OUT TABLE

Spare Part

No. | Name | Quantity | Country |

1 | Rely | 2pcs | China |

2 | Encoder | 2pcs | China |

3 | Encoder wheels | 2pcs | China |

4 | bearings | 2pcs | China |

5 | limit switch | 2pcs | China |

6 | Switch buttons | 3pcs | China |

7 | sensor | 4pcs | China |

8 | Oil tubes | 2pcs | China |

9 | Gears | 2pcs | China |

11 | circlip | 30pcs | China |

12 | Tool Box | 1 Set | China |

Recommend Products

Product Consulting

Address: 50 Meters South Of China Petroleum Gas’

Tel/Whatsapp: +86 13231741939

E-mail: sales@czdingtuorollformer.com

E-mail: formingmachine55@gmail.com

Message consultation

WhatsApp / Wechat